What could be an important development in materials occurred with an announcement from Mechnano.

Mechnano, an Arizona startup dedicated to the development of advanced additive manufacturing materials, has announced a new approach they call “D’Func”. Mechnano has developed a range of unusual 3D print materials over the past year, including a number of ESD resins that have been certified for various equipment. Their latest announcement is a new approach that promises to greatly improve the performance of carbon fiber materials.

Carbon Nanotubes and Reinforcement

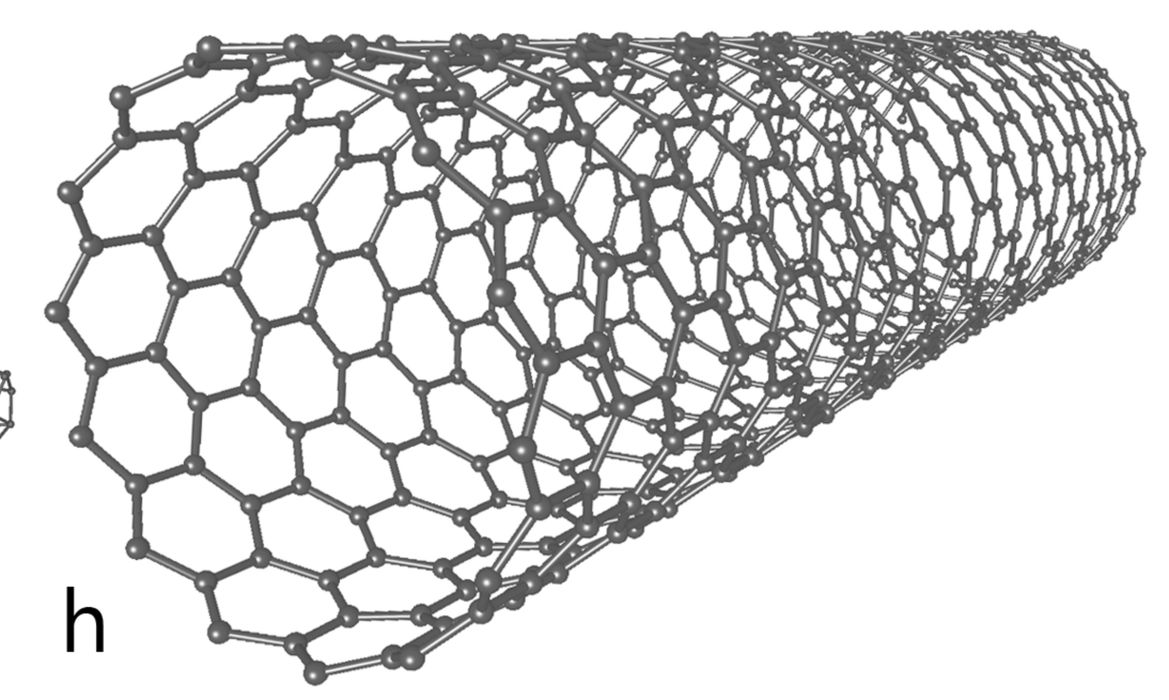

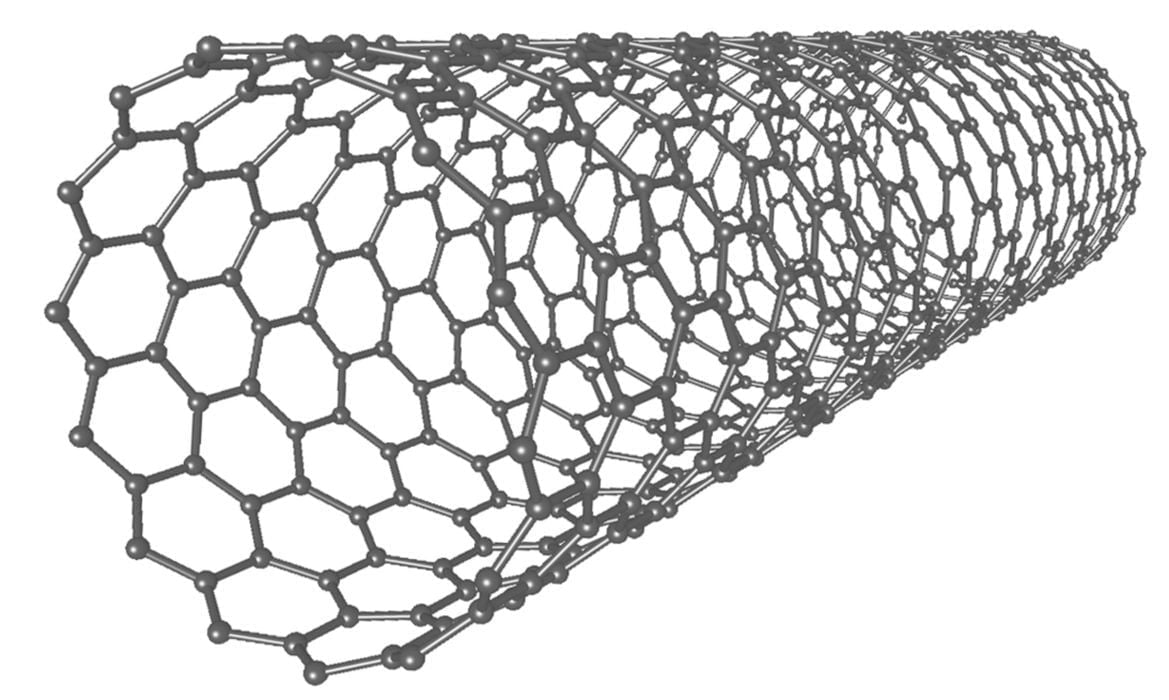

Carbon nanotubes are microscopic structures where carbon atoms are linked into a tubular configuration. The resulting geometry is unbelievably strong, and has long been desired as a 3D printing material. However, it is currently impossible to directly 3D print carbon nanotubes. As a result, composite materials that are a mix of a polymer and carbon nanotube segments are often used for reinforcement.

However, carbon nanotubes tend to clump or form “ropes”, which can lead to unexpected zones of weakness or conductivity in the resulting parts. Mechnano’s D’Func approach aims to solve this problem by mixing carbon nanotubes in a new way that uniformly distributes the reinforcing agent.

Mechnano’s D’Func Approach

Mechnano has produced an impressive 130 patents to develop the D’Func approach. Bryce Keeler, Mechnano President, explained that “D’Func provides Nano-Uniform ESD protection throughout the part, regardless of the process, which is why it is becoming the industry standard for AM providers who want consistent, reliable, Nano-Uniform ESD properties.”

Mechnano will be producing a series of 3D print materials using D’Func, and they will be labeled as such. This is very good news for 3D printing, as it is the beginning of a series of extremely strong materials that will almost certainly open up many new applications that require high-strength parts.

Applications for D’Func

D’Func promises to provide a uniform distribution of carbon nanotubes in composite materials, which will significantly improve the strength and conductivity of resulting parts. As a result, this new technology is poised to open up many new applications that require high-strength parts, including aerospace, automotive, and medical industries.

Conclusion

Mechnano’s D’Func approach to mixing carbon nanotubes is an exciting development in materials technology. With the ability to uniformly distribute carbon nanotubes, parts will be much stronger and better suited for high-performance applications. We can expect to see many more companies adopting this technology in the coming years as Mechnano continues to innovate in the additive manufacturing space.

Via Mechnano