I took a closer look at 3D printed meat startup MeaTech.

After adding the company to our 3D printing company stock tracker last week, I thought readers would appreciate an overview of the company. The Israeli company has been around for only a few years, but it appears to be one of today’s leading companies in the field of 3D printed cultured meat.

Two Ways To 3D Print Meat

3D printed meat is an emerging technology that has taken two paths.

One approach is to use vegetable sources as input material. These are combined in ingenious ways with various additives to produce meat-like materials. By 3D printing them, it’s possible to produce analogs of actual meat cuts. This type of product is typically called “alt-meat”.

That’s not the approach of MeaTech, which has pursued the other approach: growing vats of actual animal cells in a bioreactor, then harvesting them and 3D printing meat cuts. The results are essentially the same as real meat cuts down to the cellular level, but having an entirely different — and more attractive — production process. This type of product is typically called “cultured meat”.

It may be hard to believe, but the meat products produced by MeaTech actually contain real meat cells, identical to those found in animals. They are the same cells, except that they were grown inside a bioreactor instead of inside, say, a chicken.

Advantages of 3D Printed Meat

There are multiple advantages to this approach:

- Entirely independent of weather

- Isolated from the outside environment, minimizing or eliminating disease or parasite issues

- Can be located anywhere there is water and power, even in urban areas

- Decreases shipping requirements by producing meat where it is required

- No requirement for veterinary expertise

- Provides the same nutritional value as actual meat

- Control over the production process and not dependent on animal lifecycles or seasons

- Is notably more ethical than traditional agriculture

- Consumes far less resources to produce the same amount of meat

Cultured Meat Efficiencies

Let’s talk about last point a bit more, because it’s likely the most important.

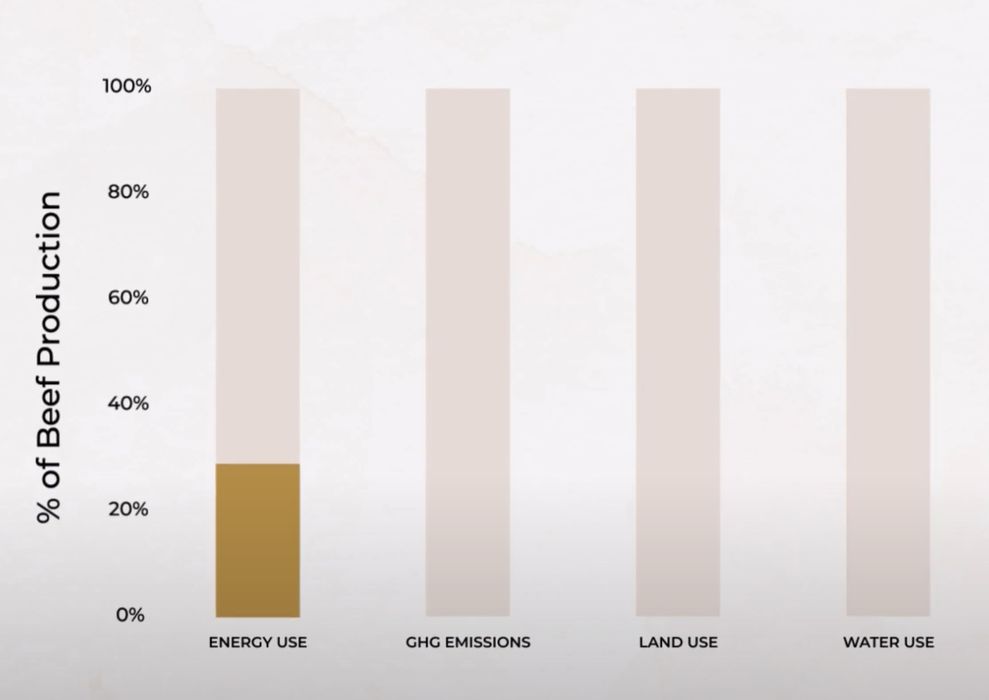

The 3D printed meat approach is vastly more energy efficient than traditional approaches, which require feeding and handling live animals for long durations. Cultured meat is created within a bioreactor that occupies a mere fraction of the land space required for animal production.

Due to the enclosed nature of the bioreactor and lack of a live animal, the need for water is minimized. Normal production of meat animals requires considerable amounts of water, while the bioreactor requires very little in comparison. This is an important factor, because the ongoing climate emergency could alter future weather to not provide as consistent rainfall as we’ve been accustomed to.

This chart shows the savings obtainable with the MeaTech approach:

MeaTech Products

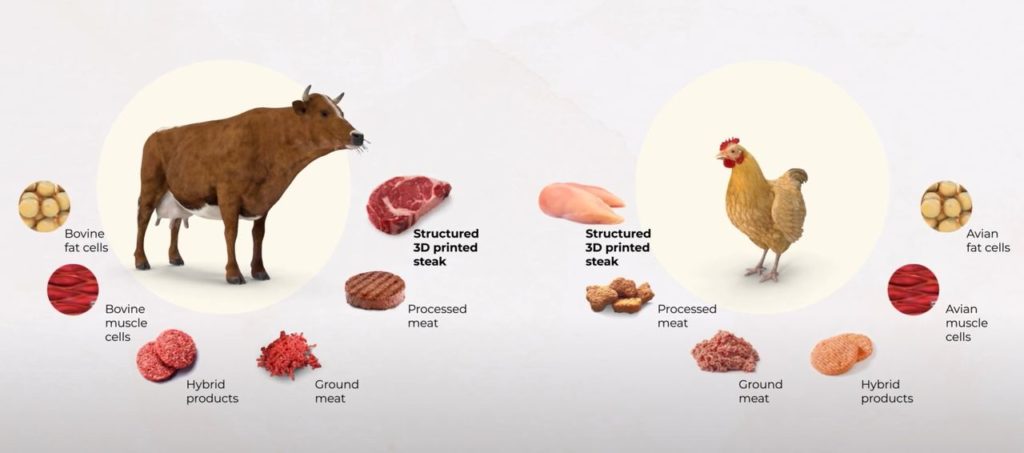

The MeaTech process is multi-stage. The first step is to isolate stem cells from samples taken from actual animals. These then go on to the second step, where they are multiplied and tuned in a bioreactor to create the desired cells types for meat production.

The final step is to build salable products with the cells that have been grown. MeaTech can provide generic patty-like products, but by adding a 3D bioprinter they can achieve much more interesting results.

The bioprinter allows MeaTech to build proper meat cuts by mixing meat and fat cells in desired ratios and patterns. Here you can see concept for their software, where you could, for example, specify the fat to protein ratio.

So far I haven’t mentioned a specific type of meat, and there’s a reason for that: the MeaTech process can, in theory, be used for almost any animal meat cells. While they have started their work with beef, they intend on quickly moving to avian (chicken) cells, and apparently have acquired a company that specializes in avian cells.

Their process can easily work with additional animals, including sheep, pigs, fish, or any other animal where they can source stem cells. They say their system will eventually be able to quickly switch production from one type of meat to another.

Their business plan involves building equipment and materials that would then be sold or leased by meat producers. These could be regional meat distributors, or food manufacturers requiring meat ingredients.

This 15m video explains much of their process:

With the increasing pressures of the climate emergency, it is likely that MeaTech’s compelling concept will be seen favorably by many. Those pressures may be sufficiently large to overcome pricing differences, should MeaTech’s products be priced higher than conventional meat. In the very long term it may even be that this method may be the primary source of meat for the world’s population.

Via MeaTech