Working with Additive Manufacturing Solutions Ltd and AMFG to develop SMART-APP tool for predictive material reuse.

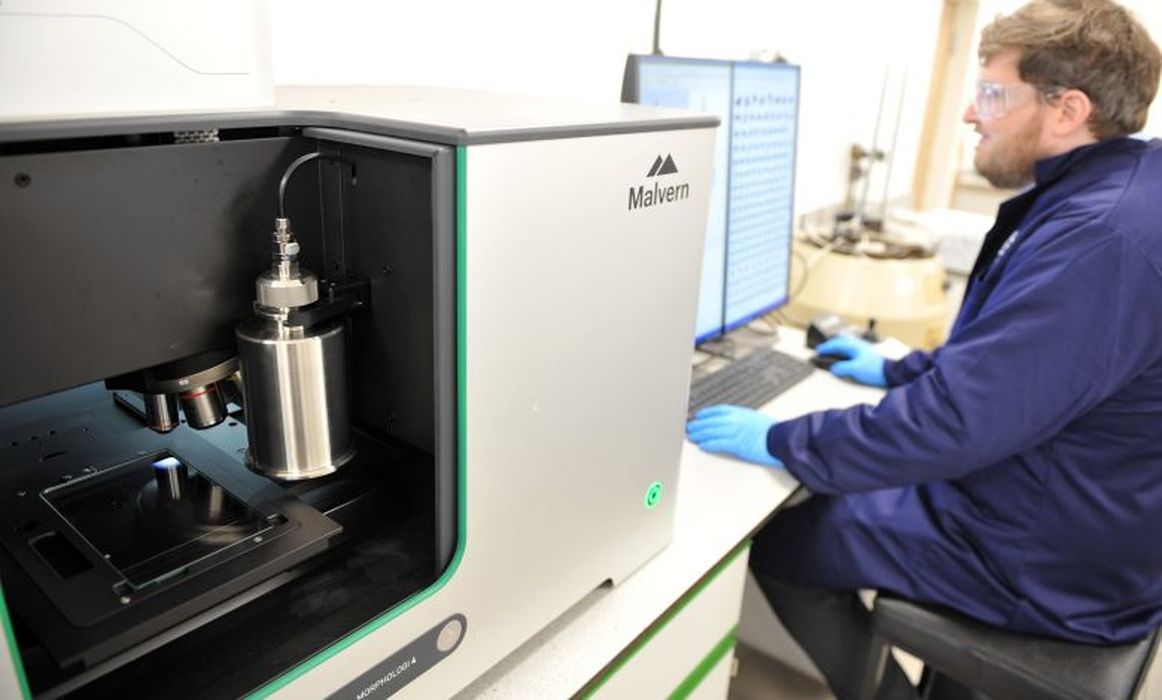

The Materials Processing Institute is leading a £600,000 research collaboration to develop SMART-APP, an AI-based tool capable of creating greater efficiencies within the Additive Manufacturing (AM) sector.

Working in partnership with Additive Manufacturing Solutions Ltd and AMFG, it aims to provide a versatile, commercial, predictive material reuse management tool enabling AM to expand by introducing greater cost efficiencies.

SMART-APP aims to enable the production of AM components, using Laser Powder Bed Fusion by introducing smart predictive models for resource efficiency and waste reduction.

Nick Parry, Industrial Digitalisation Group Manager at the Teesside-based Materials Processing Institute, said: “SMART-APP is the next logical step to continue the work the Institute has already undertaken in powder characterization. By developing an artificial intelligence tool that can help AM users create faster and cheaper ways of maximizing powder reuse, the AM industry, especially those needing to maximize the operational effectiveness of their machines.

“This predictive tool will develop and enable world-class production of AM components, with smart solutions for resource efficiency and providing longer use of materials feedstock and reducing wastage.”

SMART-APP predicts the quality change of the powder after each process and proposes alternative process parameters on used powder to extend its lifespan with a minimal or an in-specification impact on product quality.

The project is funded by Innovate UK, part of UK Research and Innovation (UKRI), the UK’s innovation agency, which drives productivity and economic growth by supporting businesses to develop and realise the potential of new ideas.

Read the rest of this story at VoxelMatters