Materialise announced a partnership with Sigma Labs that could dramatically increase the reliability of production 3D printing.

Materialise is the well-known provider of all manner of software tools for additive manufacturing, most notably their Magics suite, which is perhaps the most powerful job preparation tool around.

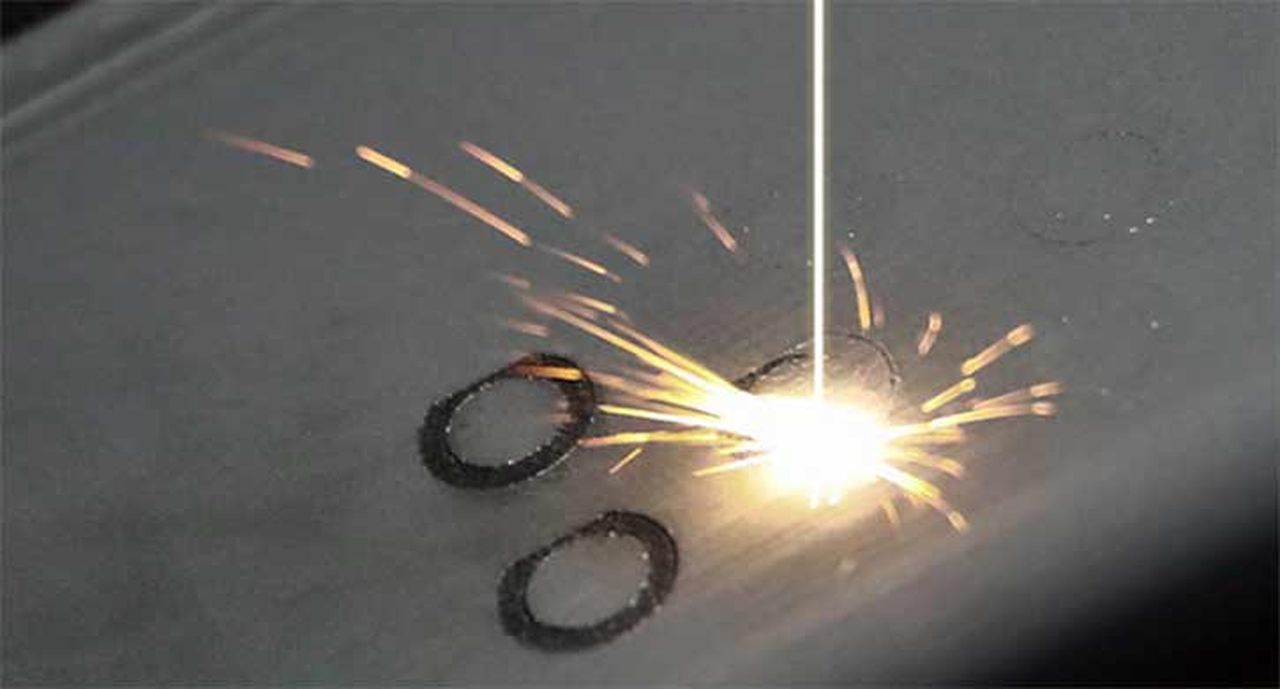

Sigma Labs is a US-based software company that we’ve looked at previously. They produce PrintRite3D, a system involving sensors and software that can monitor critical factors of a metal 3D print job and provide real-time alerts if something goes sideways.

This is a critical need for metal 3D printers, which are notorious for the difficulty of reliably producing consistent parts in serial production. Not only can powder be laid down slightly differently on each layer, but each machine’s hardware components are slightly different. These seemingly minor variations can accumulate into print failures, particularly on metal parts requiring notable strength. That’s because the microstructure of the fused metal particles determines the strength, and that in turn is created by the melting and cooling process that PrintRite3D monitors.

PrintRite3D is composed of both software and a sensor pack that must be installed on the machine. Evidently Sigma Labs is able to install PrintRite3D on a variety of popular metal 3D printers currently on the market.

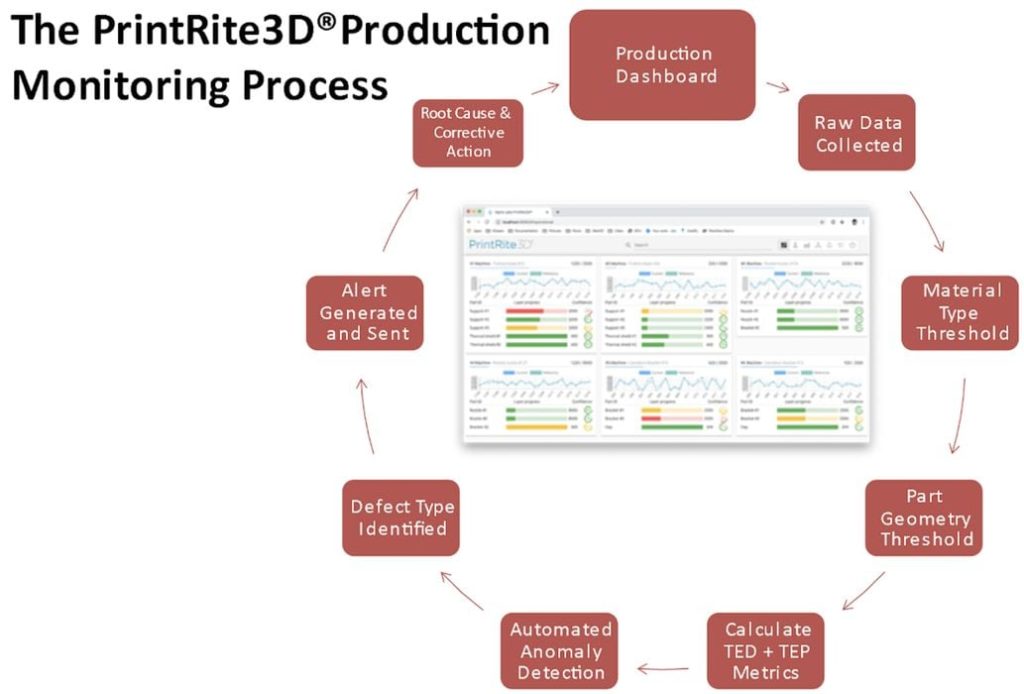

The system works by comparing sensors results against a comprehensive database of prior print job readings, making it easy for PrintRite3D to quickly detect issues.

Here is a chart of PrintRite3D’s production monitoring process:

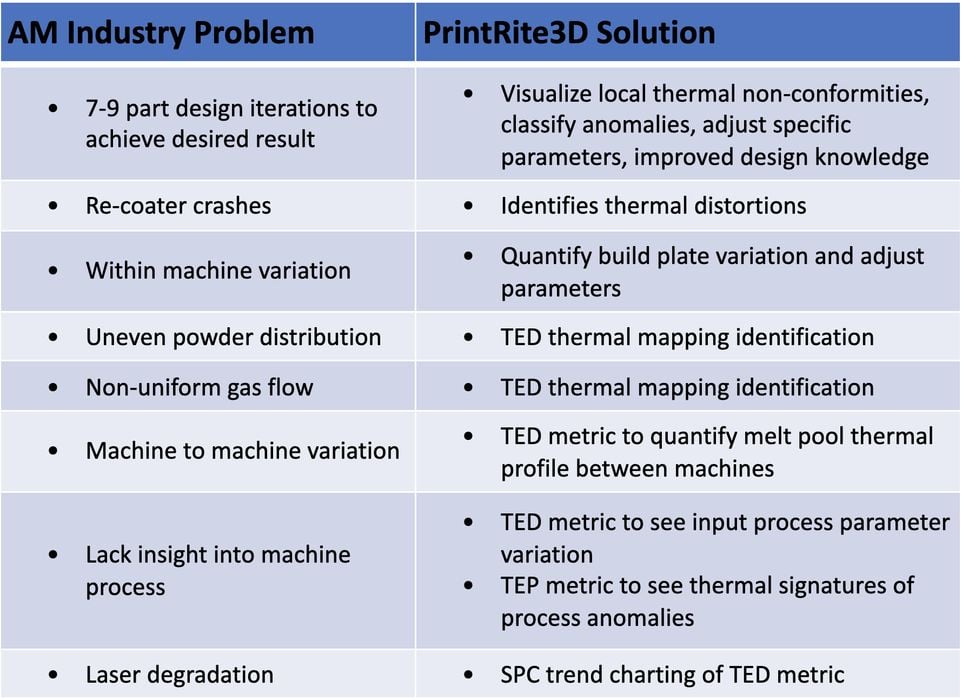

And these are the factors being monitored by PrintRite3D:

As you can see, PrintRite3D would allow an operator to know if a part wasn’t produced in optimal conditions, and possibly even stop the print before too much material and printer time is wasted. This is a very valuable capability.

As such, it’s my understanding that a great many metal additive manufacturing operations already use PrintRite3D.

Materialise’s MCP, or Materialise Control Platform, is a combination of hardware and software that provides advanced control of not only metal 3D printers, but many 3D printers using laser-based processes, including SLS.

MCP allows the operator to control over 250 print parameters directly, enabling precise results for each machine & material combination.

So what is this partnership all about?

The two companies have joined their functions together. Materialise explains:

“The Materialise Control Platform (MCP) is an embedded hardware solution that provides end-users more control over the AM process. By integrating the MCP with Sigma Labs’ PrintRite3D® sensor technology, the companies have created the possibility to identify quality issues and intervene to correct them in real time. This improves the productivity in metal AM and reduces scrap rates, paving the way for manufacturers to advance their operations and implement metal AM in serial production.”

My understanding is that PrintRite3D on its own reports issues and then the operator must take action. Now, MCP allows that intervention to take place easily and quickly. The combination of the two means that the operator should be far more aware of issues during prints and able to take immediate corrective action.

Materialise CTO Bart van der Schueren said:

“The platform we’ve developed eliminates one of the most common roadblocks for manufacturers interested in using metal additive manufacturing for serial production. The platform is open and flexible allowing manufacturers to take control of their specific processes to fit their unique applications. This makes it possible for customers to leverage their expertise and truly take advantage of the customization and localization benefits that AM provides.”

However, as this system is composed of both hardware and software, some work with equipment makers is required. Materialise explains:

“Materialise and Sigma Labs will collaborate with end-users and machine producers to refine processes for their unique applications. The companies are seeking partners across industries who are interested in expanding their use of metal AM in serial production.”

This development is obviously a powerful step for those using additive manufacturing, particularly in metals. It should provide a means for operators to reduce wastage costs and generally improve the throughput and efficiency of metal 3D printing processes.

To me the most exciting part is yet to come. While the two companies haven’t mentioned so, it would appear possible for a deeper degree of automation to be developed with this joint platform. Imagine if instead of the operator being notified, the system itself made the correct adjustments and allowed the job to continue and complete successfully? It would appear the pieces of that style of solution could be at hand, and we might see something like this evolve from the MCP PrintRite3D technology.

Via Materialise and Sigma Labs