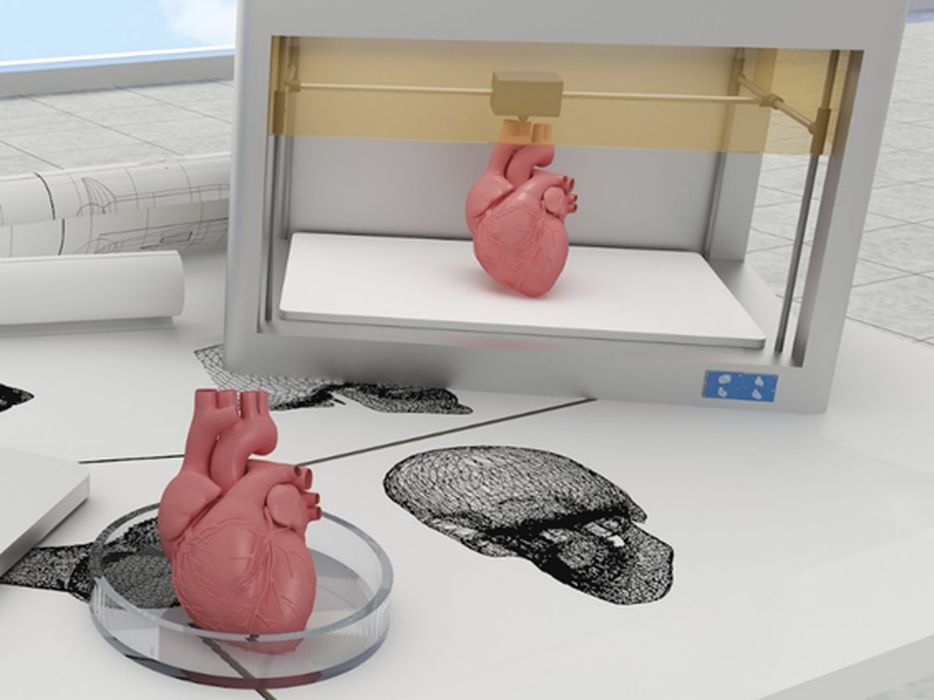

Charles R. Goulding and Preeti Sulibhavi review the concept of 3D printed human organs.

“I actually believe there is no organ in the human body that can’t be printed.” This is a quote from United’s CEO, Martine Rothblatt, formerly the founding CEO of Sirius Satellite Radio who pivoted careers to med-tech in the nineties after her daughter developed a rare lung disease.

Bioprinting tissue isn’t a novel concept in today’s world. 3D printers can print human skin and retinas. But bioprinting has been limited to tissues that are very small or very thin and lack blood vessels. United is trying to change this.

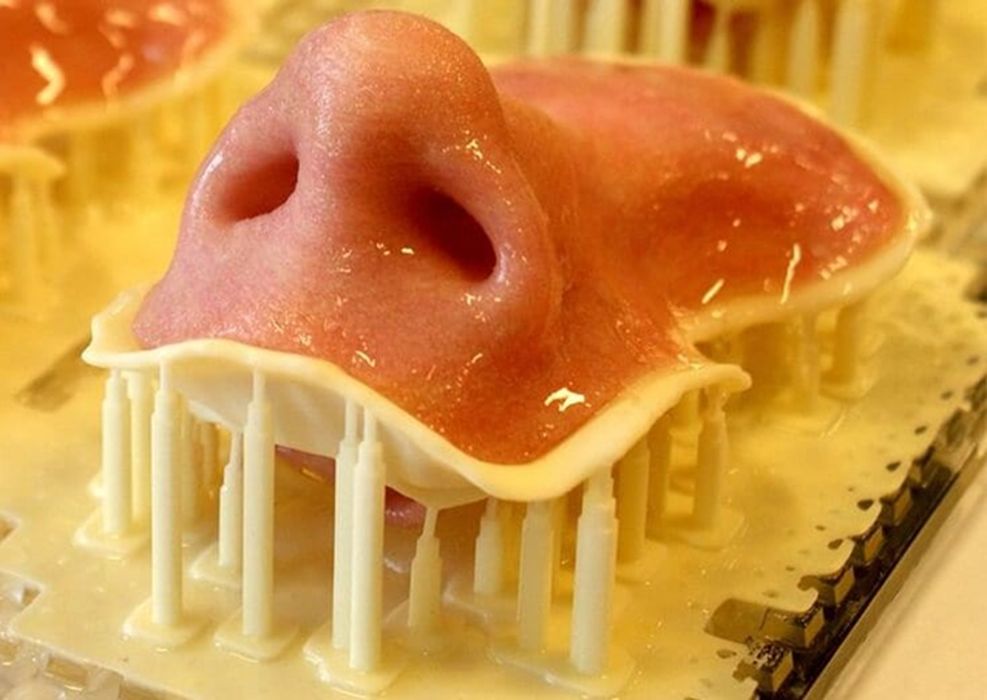

When United began this herculean task, it found that the problem with other bioprinting projects was that they used extrusion methods, squeezing cells and proteins through fine needles. This is likened to pushing water balloons through a straw, which limits printing resolution to the size of the cell. United has taken the opposite approach, to 3D print a lung scaffold first and then infuse it with human cells, a process called recellularization.

There is early evidence that a collagen matrix can be turned back into a functioning lung. In 2018, in an experiment partly financed by United, Harvard University experimental surgeon Harald Ott reported that he’d pumped billions of human cells (from umbilical cords and diced lungs) into a pig lung stripped of its own cells. When Ott’s team reconnected it to a pig’s circulation, the resulting organ showed rudimentary function, although the experiment lasted only an hour.

“You do get blood through the system, and you do get gas exchange,” says Finn Hawkins, a stem-cell biologist at Boston University, who is not involved in United’s project. “That is remarkable. But it’s a long way to transplantable organs.”

This type of regenerative medicine is the “fountain of youth,” the “holy grail,” so to speak of today’s healthcare industry. So many people are on waiting lists for organ donation that each day seventeen people die waiting for an organ transplant according to the Health Resources & Services Administration (HRSA).

We have covered how scientists are Achieving Breakthroughs in Drug Discovery with 3D Bioprinting as well as how certain corporate acquisitions can impact bioprinting activities at leading companies. The government is in fact now supporting the bioprinting industry through Biden’s Biotech Executive Order.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

What Rothblatt must have gone through upon hearing the diagnosis of her daughter can only be comprehended by those who have similar experiences. What she did as a result of this news was truly remarkable and we believe that the future of the 3D printing industry is bioprinting and med-tech to improve health outcomes for millions of people. This is the next 3D printing frontier.