Charles R. Goulding and Preeti Sulibhavi look at ways 3D printing could be used to offset inflationary factors.

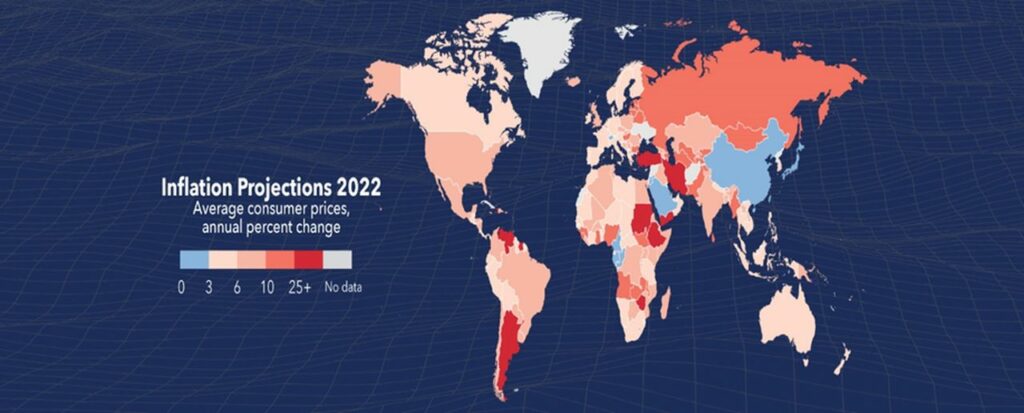

In the current high inflationary environment virtually all costs are increasing and need to be managed.

Labor Costs

Here it is important to make sure that you are providing your team with appropriate raises reflecting both inflation and merit otherwise in the current labor tight environment you will lose them. Benefit costs will typically rise proportionately with the firms benefits overhead percentage. With proposed legislation new employees will automatically be enrolled in the firms 401K plan. One way to manage labor costs is to use automation where appropriate.

Raw Materials

Commodity prices for raw materials have reached all time highs for many raw materials. Some companies have managed raw materials costs by controlling supply. Apple has done this with semi-conductors and steel companies have purchased scrapyards. In certain situations alternative materials can be substituted.

Components

Prices for many components have also reached all time highs. Some solutions include near shoring and using 3D printing to create components like KB Homes, the national home builder, now shifting to Whirlpool for appliances, which uses extensive 3D printing. Generative design and topology can often simply design and reduce the number of required components.

Increasing Sales Prices

No matter how well you manage the above costs some product sales price increases are almost inevitable in the current inflationary environment. In fact, your customers are experiencing price increases from most of their vendors. Try to refrain from the uniform price increases and be thoughtful about product price increases. Be prepared to justify your price increases with specific data related to increases in the cost categories discussed above.

Warren Buffet recently commented that one way to combat inflation is to be exceptionally good at something.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software. Higher costs for technical labor and materials used in prototypes will generate higher R&D tax credits.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Most U.S. businesses are not accustomed to operating in a high inflation environment. Taking a comprehensive approach should help manage through this volatile period.