Materialise announced a powerful new capability in an upcoming version of their Magics suite.

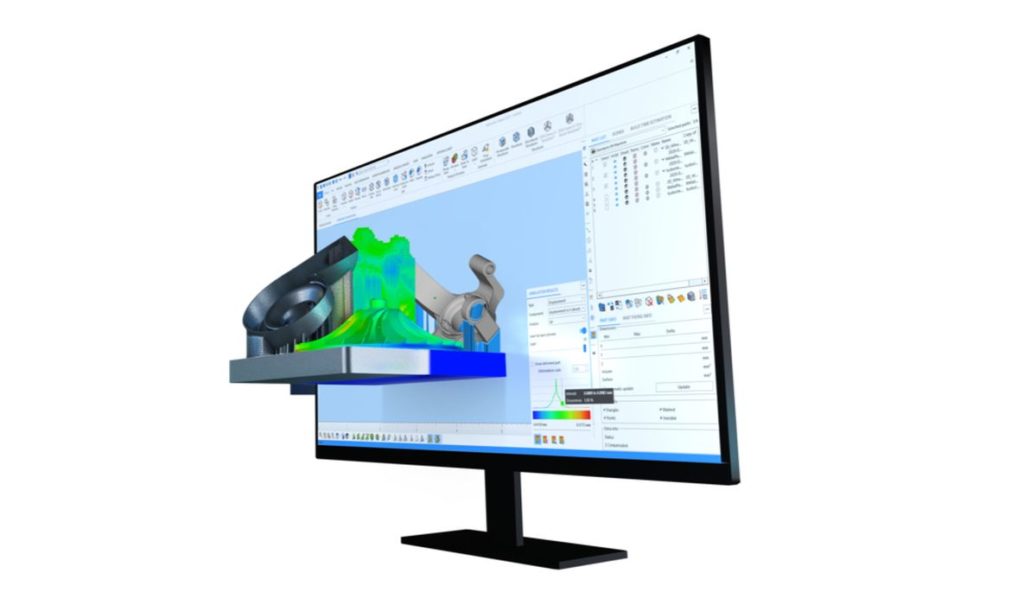

Magics is the flagship software product for the Belgian company, and it’s used worldwide by additive manufacturing operations to prepare 3D print jobs. The tool includes the ability to track and manage print orders from initiation to fulfillment, including the planning of production jobs and even post-processing steps.

The software includes very sophisticated repair and setup options that can squeeze more throughput out of a 3D printer. In fact, Magics is compatible with and can build machine-specific print jobs for virtually all popular 3D printers in the industry.

The workflows in Magics typically involve mesh files, that is, STL, OBJ, 3MF and the like. These are geometric descriptions of the exterior surfaces of 3D objects, often used in 3D printing. Mesh files are typically created by exporting from a CAD system, where the object’s original design is created. Mesh files are usually quite large and cannot easily be modified after export, aside from basic repairs.

The change coming in Magics version 26 is that they’ve licensed Siemens’ ParaSolid software.

Parasolid is a geometric solid modeling kernel, in other words, core software that performs solid 3D modeling. This provides the ability to perform operations on 3D models, such as boolean modeling, surfacing and much more. The key difference here is that Parasolid works not only with CAD objects, but also with meshes and even lattices. Materialise explains:

“Parasolid is at the core of the Siemens’ Xcelerator portfolio’s open and flexible ecosystem and has been adopted by more than 200 software vendors giving end-users 100 percent 3D model compatibility across 350+ Parasolid-based software applications.”

The bottom line here is that Magics 26 will include BOTH mesh and CAD workflows, which should greatly simplify the efforts of Magics users, because CAD formats can be directly handled by the Parasolid kernel. Materialise explains what this means to Magics users:

“With Parasolid technology, Materialise will add native CAD workflows within Magics 26, providing an additional toolset on top of mesh functionality. This powerful combination of trusted solutions will allow users to continue iterating CAD designs in Magics to prepare for additive manufacturing processes, improving productivity and providing cleaner, more accurate and fit-for-purpose data.”

Materialise VP of Software Stephan Motte said:

“For years, the 3D printing industry has discussed whether CAD or mesh is the preferred workflow for file preparation. We believe both offer unique benefits and a seamless integration of both formats will provide users with the optimal workflow.”

While this change enables new paths through product development and production workflows, it’s likely Magics 26 users will have to experiment with the new capabilities to fully optimize their specific workflows. But by doing so, it’s very likely cycle times can be improved, and that’s a good thing.

Via Materialise