I had a chat with the folks from Lynxter to find out what they’ve been up to.

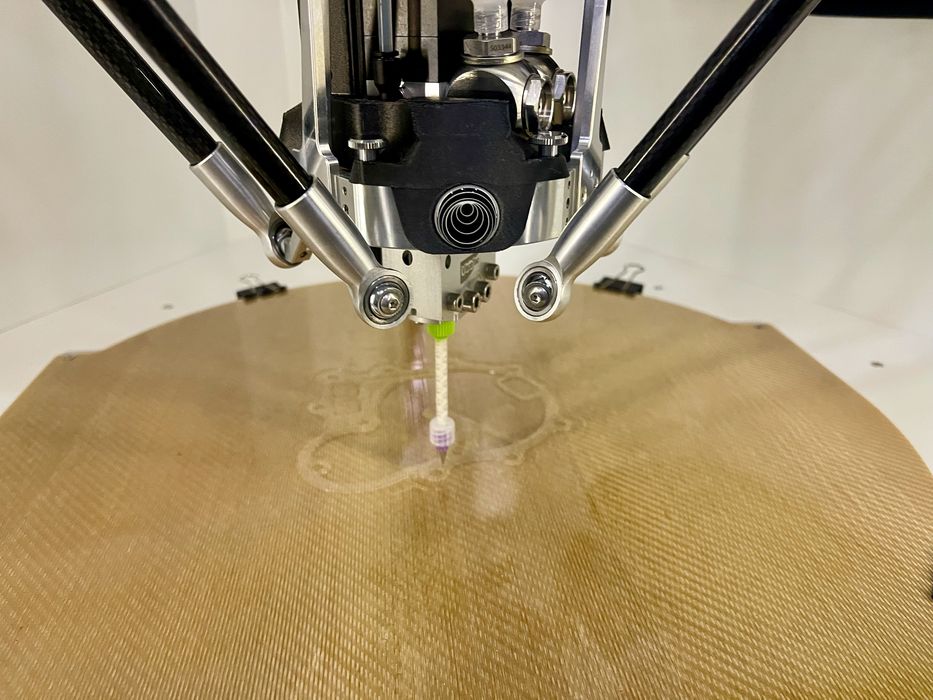

The French company launched several years ago as a school project, but soon commercialized. Initially, their tall delta-style 3D printer offered several unique features, such as water cooled extruders for high temperature materials, and quick tool swapping through magnetically attached print heads.

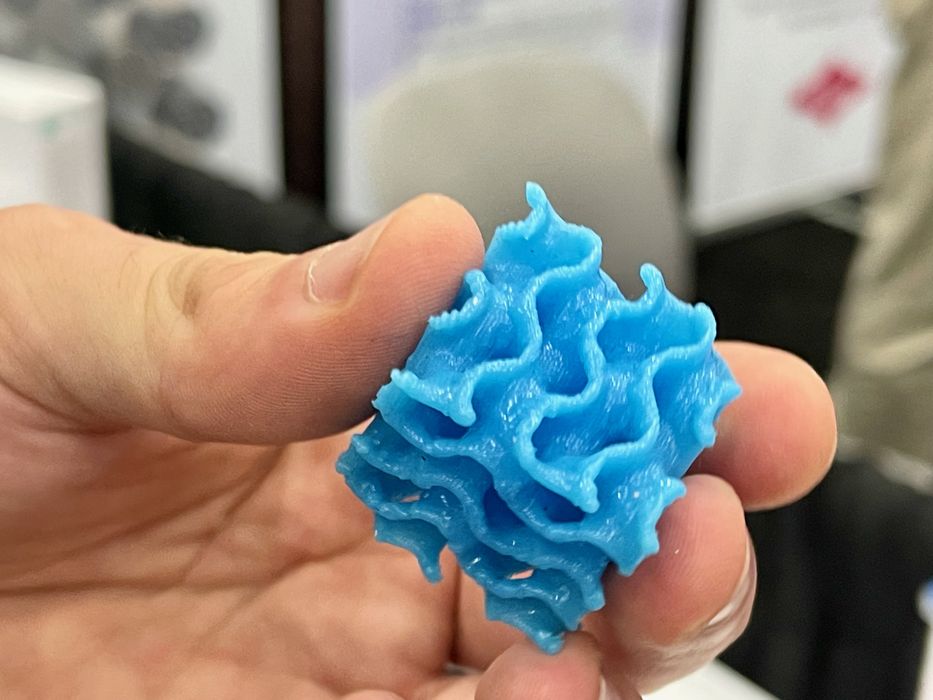

Later, the company added “liquid” tool heads that could deposit a variety of squishy materials through a syringe-like mechanism. These include materials such as silicone, resins, polyurethane and even wax.

Today the company seems to have perfected the technology, and you can purchase a device from them that is capable of 3D printing a wide variety of thermoplastics, silicones and ceramics.

They’ve strongly leveraged their original machine’s ability to quick-swap tool heads, resulting in a multi-material device that’s ready for professional use.

The latest news is that the company has developed yet another tool head, this one for 3D printing flexible materials, which are notoriously difficult to 3D print on Bowden systems, which the Lynxter S600D uses.

For materials, Lynxter is apparently developing new materials to be announced at this year’s Formnext exhibition in November. However, it sounds like they are working on a way to 3D print silicon carbide. That’s a very special material, a semiconductor, that is extremely hard. This means it could be used for applications where there are extreme mechanical requirements, like vehicle brake pads.

They also seem to be adding more silicones to their widening silicone selection. We were also told they’re working on an alumina zirconia material that will not require debinding, and apparently can go directly to sintering. This could avoid an entire post processing step.

On the corporate front, Lynxter is widening their market. Based in France, their original market is mostly Europe. However, they’ve set up a network of resellers in the EU, and are to pilot this same approach in the US market.

It seems that Lynxter is doing quite well, and it’s likely you’ll be hearing a lot more from them in the future.

Via Lynxter