Charles R. Goulding and Preeti Sulibhavi look at the use of Lucite and similar materials in industry and 3D printing.

Lucite is a high-quality, trademarked product of acrylic resin that was created and developed by DuPont in the early 1900s. This acrylic plastic resin is used primarily in windows and fashionable interior and furniture design due to its strength, crystal transparency, and flexibility along with its resistance to UV rays, wind, and water.

With so many decorative home items such as furniture, lighting fixtures, bathroom fixtures, kitchen and home appliances being 3D printed it should not surprise anyone that Lucite is becoming a go-to material for such objects. Not only for its aesthetic appeal but its durable and often scratch-resistant properties as well.

There is a myriad of consumer products where 3D printed transparent materials are highly useful. They include cosmetics packaging, kitchen products, and food and beverage containers. There are also more functional applications as well, such as acrylic adapters.

Lucite & 3D Printing

Multi-material 3D printing technology enables the fabrication of translucent parts and components to be more efficient and convenient.

Polymethyl methacrylate (PMMA), commonly referred to as acrylic, is a transparent thermoplastic often used as a more durable substitute or alternative for glass. Therefore, because Lucite is an acrylic-based substance it can be 3D printed.

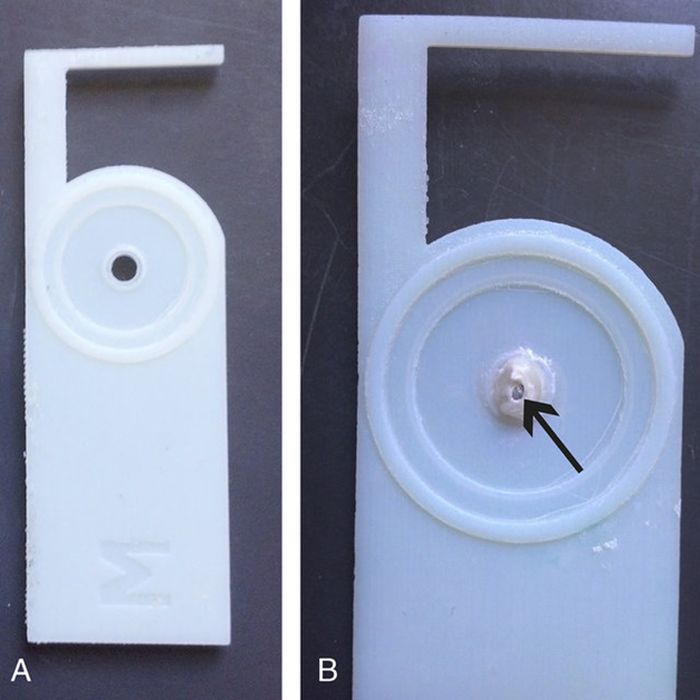

Among the more relevant uses of Lucite and 3D printing include med-tech products. One example is using Lucite to replace human teeth. There are companies such as Lucite Diakon and Vertex-Dental that are already creating such teeth.

Uses for Lucite in the medtech industry include hearing aids, prosthetics, and eyewear.

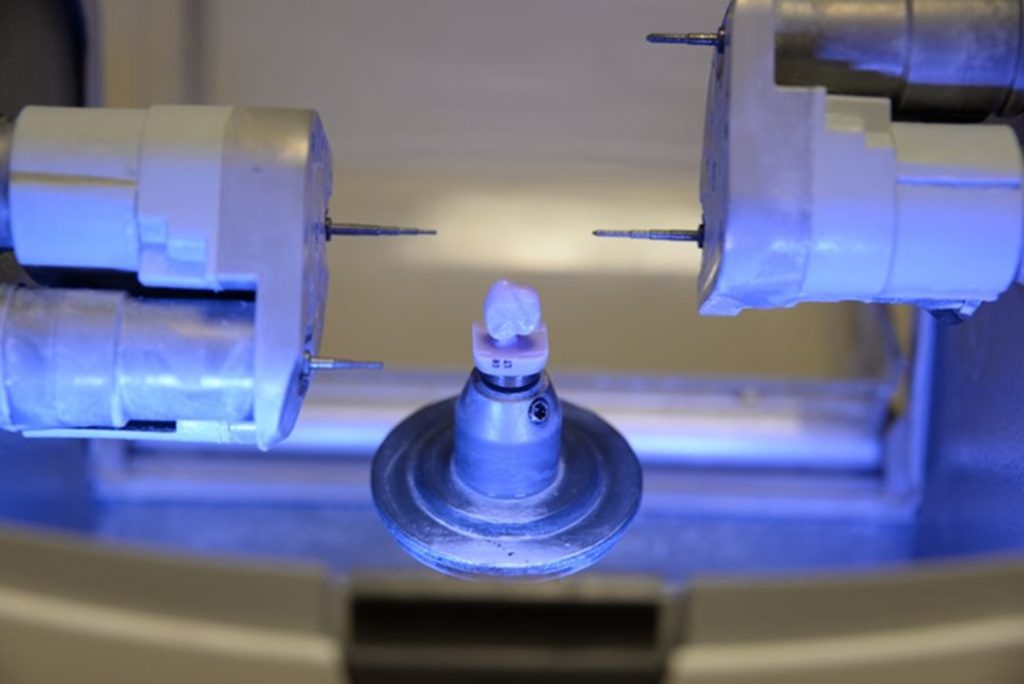

VeroClear, a Stratasys PolyJet material, is a transparent substance that simulates acrylic. Like PMMA, VeroClear is used as an alternative to glass. For prototypes that need to simulate glass or clear polymers for eyewear, VeroClear and VeroUltraClear are ideal choices. Nidek Technologies, an Italian company specializing in ophthalmology R&D, used VeroClear to prototype a special new optic device.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Clear Things Up

It appears Lucite is here to stay. The 3D printing industry can be certain there will be more demand for fabricating various items with this material. Many major 3D printing companies, such as Stratasys, are ready for this trend to continue.