Researchers have developed a method of 3D printing composite material at relatively low temperatures.

The research was undertaken by Dr. Mostafa Yourdkhani of the State University of Colorado, and recently highlighted in an ACS paper with the title “3D Printing of Short-Carbon-Fiber-Reinforced Thermoset Polymer Composites via Frontal Polymerization”.

Composite materials are highly desirable by industry because of their great strength and light weight. They’ve actually been used for years, but mostly using conventional manufacturing techniques. Those don’t have the advantages of 3D printing, which can reproduce almost any geometry without regard to the making process.

Some 3D printing of composite materials is being done, but almost exclusively with thermoplastic materials. The strong fibers are mixed in with a thermoplastic polymer, which acts as a binder for extrusion, sintering, etc.

On the other hand, there has been very little progress with thermosets, which are polymers that irreversibly solidify once engaged. Thermosets bond chemically, rather than through heat, so the making process is inherently low temperature.

But most thermoset materials are either too liquid or cure too slowly for effective use in large format 3D printers. One exception to this is the GDP process used by Massivit, in which they deposit a photopolymer gel, which gradually solidifies in a UV light bath.

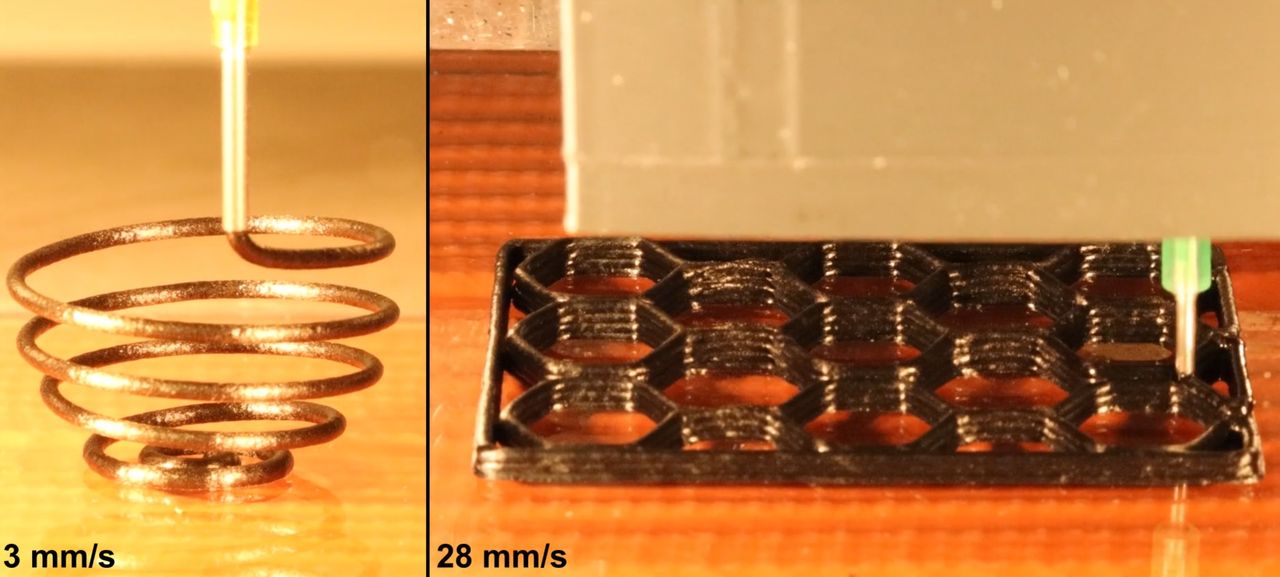

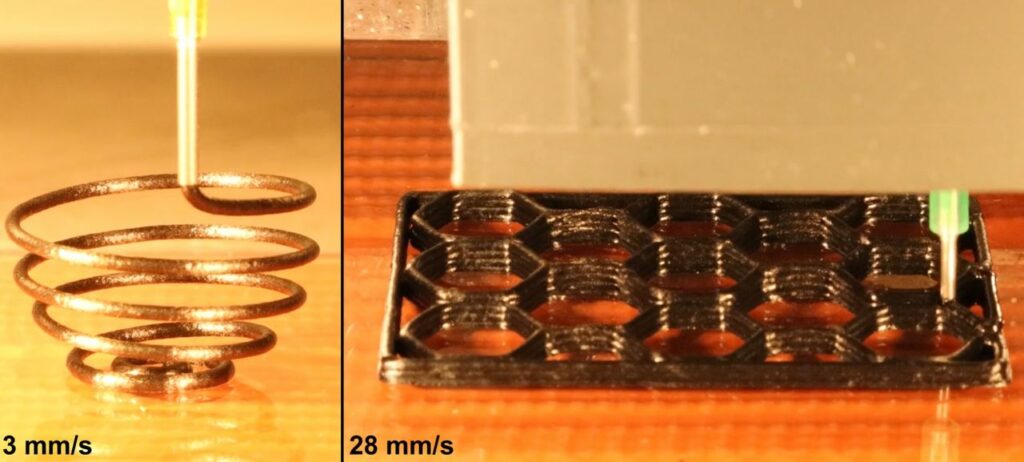

But what if you could 3D print a fiber-reinforced thermoset material that solidifies at great speed? Watch this video to see what could happen:

In the video you will see that the thermoset freezes almost instantly when extruded from the nozzle. This makes it possible to build extreme overhangs and other complex structures, quite different from Massivit’s GDP, which seems to avoid significant overhangs.

The research paper explains:

“Here, we demonstrate a new technique for in situ printing and curing of carbon-fiber-reinforced thermoset composites without any postcuring or postprocessing steps. Upon extrusion and deposition of the composite ink from a printing nozzle, the ink is cured via frontal polymerization, leading to rapid printing of high-quality composites. Tailoring the processing conditions allows for freeform or rapid, supported printing of 3D composite objects with zero void content and highly oriented carbon fiber reinforcements.”

This process seems to be unique and unprecedented in the 3D print world.

You’ll note the very rapid speed of printing, which suggests that objects could be created rather quickly. Also, there remains the possibility of engineering parallel deposition toolheads, which could dramatically increase deposition rates.

My suspicion is that this technology will sooner or later (likely sooner) become commercialized. However, it will face the fate of most unique 3D printing processes these days.

Ever since the dawn of 3D printing, a dilemma has faced every new technology: convincing people to use it. The issue is that adoption requires buyers to somehow conceive of the new things they could do with the technology — that are inherently different from the things they do today. It’s very hard for most people to think beyond what they currently do, and that requires considerable persuasion, demonstration and convincing.

This particular thermoset technology seems so utterly different from current capabilities that it will surely fall into this zone of unknown.

Eventually the parties realize what could be possible with the technology and adoption begins. But this process takes in some cases years, and that will require significant investment for a startup company to survive until that occurs.