The 3D-Rotoprinter has a motion system you have to see to believe.

Most 3D printers operate with a cartesian motion system, where the build chamber is tracked with X, Y and Z points. There are some other systems that use a cylindrical build chamber with a height and diameter, often seen on delta-style equipment.

Two other examples of rotational motion systems would be the massive dp-Polar i2 HSR system that has a spinning build plate, and the small scale Polar3D device.

However, the 3D-Rotoprinter has something quite different.

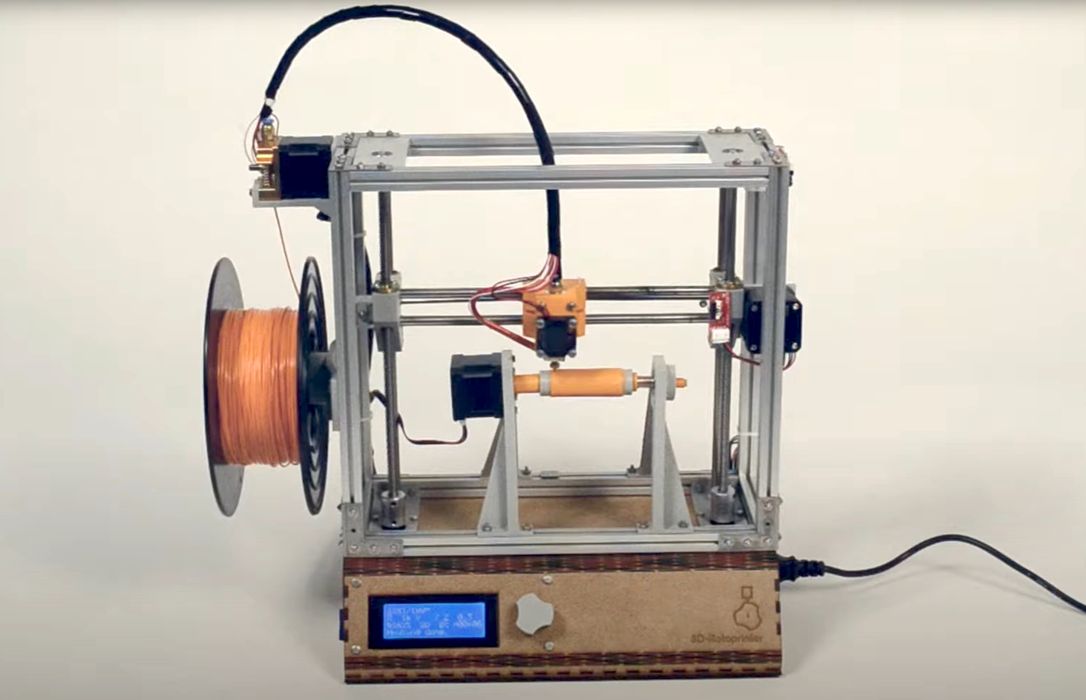

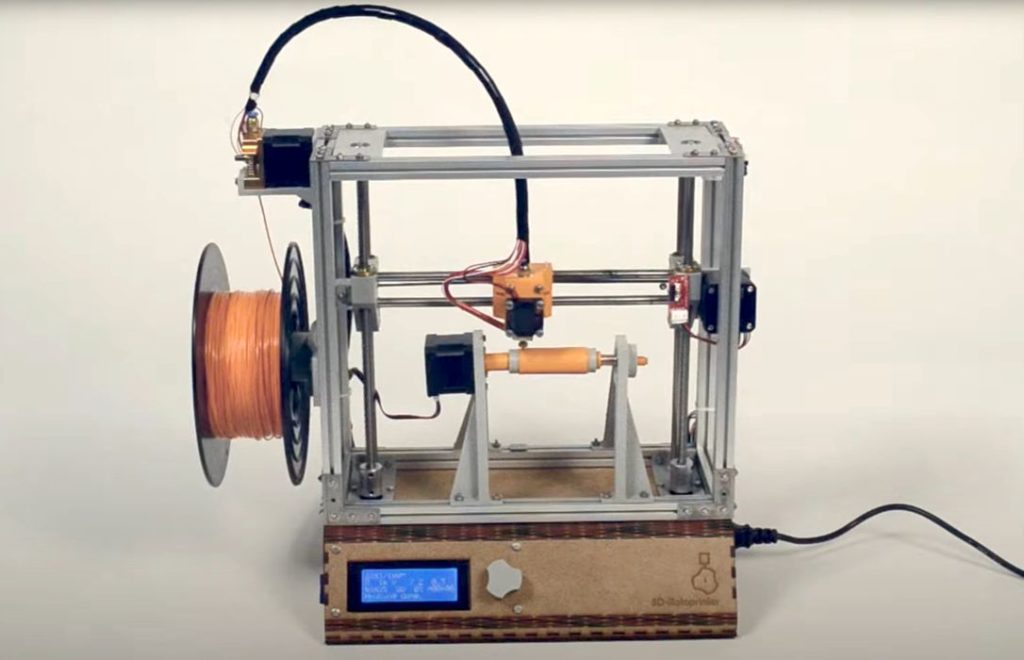

It’s basically a standard FFF device, except that the motion system is cylindrical. This is a bit hard to understand at first, but just imagine if instead of a rectangular build plate, the build surface was rolled up into a cylinder.

Using this approach, a 3D printer need only have a direct-drive rotating motor for the Y axis, and standard cartesian-style motion systems for the X and Z axes. Watch this video to see how it works:

But how can this work? Each 3D print job requires a “blank” to serve as the cylindrical build surface. This is inserted onto the 3D-Rotoprinter much like you’d mount a chunk of wood on a lathe. However, as the printer spins the blank, the extruder can lay down material on it.

The question is, what happens to the blank? The answer is that it is simply removed after printing completes. This means that each print produced on the 3D-Rotoprinter will have a cylindrical hole in the middle, but that’s actually OK or even desirable for many applications.

According to the 3D-Rotoprinter website, it was developed by Jonas Duteloff as part of his studies at Burg Giebichenstein University of Art and Design. He has apparently been working on the device since then, but as of now it does not appear you can purchase one.

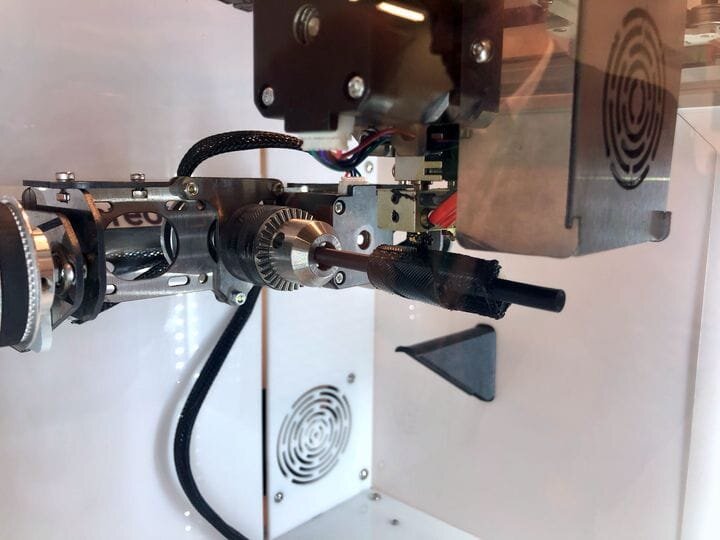

As unusual as this approach might be, I have actually seen something like this previously. At Formnext 2019 I had a chance to examine Volgograd-based Stereotech’s “5D STE520” 3D printer. That device had a single mount for a cylindrical blank, and could 3D print in a manner similar to the 3D-Rotoprinter. However, they have more axes of movement (hence “5D”), allowing more complex 3D models to be printed.

I hadn’t heard from Stereotech for quite some time, so I checked up on them and found they’ve continued development of their device, and now offer a larger volume version. It seems that if you’re interested in this approach and are looking for a commercial option, then Stereotech might be where to go.

Via 3D-Rotoprinter (Deutsche) (Hat tip to Benjamin)