We were able to take a close look at the Kings JS-FGF-1800 3D printer, from the inside.

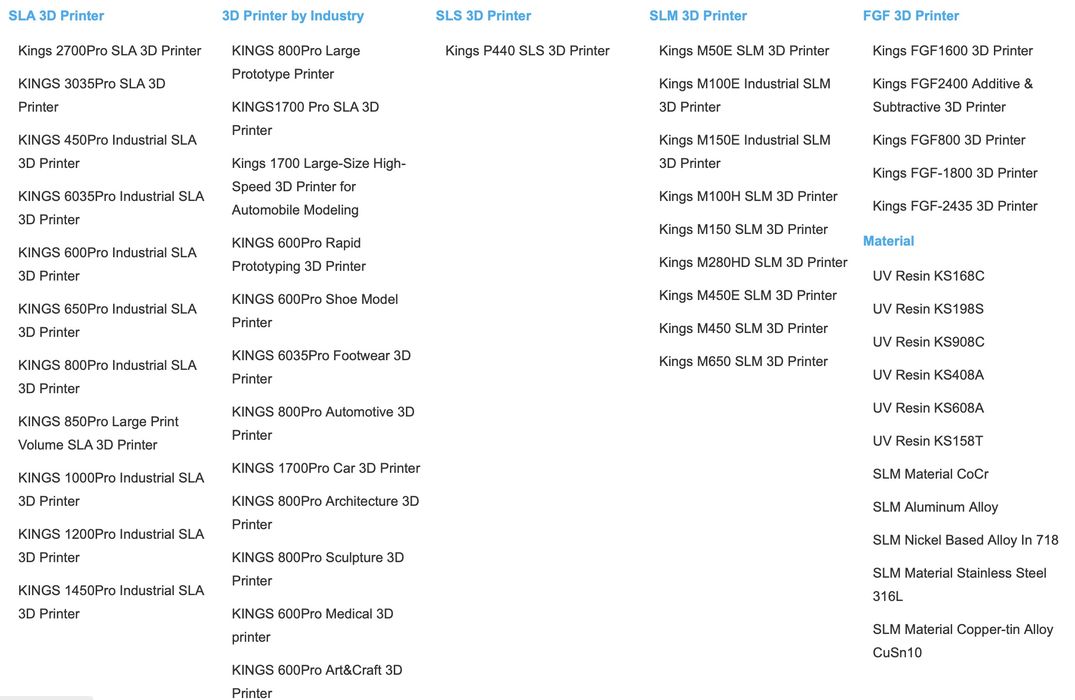

Kings is a Chinese manufacturer of industrial 3D printers, and they’re only now becoming more well known in the West. The company produces a vast array of 3D printers using multiple 3D print processes. I won’t describe them all here, but you can see this screenshot of their current product line:

Interestingly, they do not offer a FFF device. However, they do offer an FGF device. FGF, for those that are unfamiliar, stands for Fuse Granular Fabrication: pellets instead of filament.

The reason for the use of pellets is that material in that format is far less expensive than filament. Filament is actually made from pellets, so you’re basically cutting out an entire manufacturing step by using pellets directly.

This is quite advantageous for larger 3D prints that consume more material. It turns out that all of Kings’ products are rather large.

We were able to check out — from the inside — one of their “midrange” models, the JS-FGF-1800. In spite of laying in the middle of their FGF line, the 1800 is a truly enormous machine, as you can see in the image at top. How big is it? We literally had a meeting with company representatives INSIDE the machine. That’s entirely possible when the build volume is 1800 x 1300 x 1300 mm.

That leads to me to another finding: we’re told many of the customers of this device use it to produce furniture. The 1800 can deposit up to 12kg of material per hour, and that’s quite impressive.

The machine’s pellet hopper holds up to 50kg of material, so in theory the machine could run flat out for four hours or so before the operator would have to pour in more pellets.

The toolhead’s extrusion nozzle can range from 1mm all the way up to 8mm for fast, but coarse prints. They say a chair of the type in the image can be printed in only four hours — or one hopper.

While company representatives mentioned PLA, ABS, PETG and “others”, I expect the material compatibility to be quite broad as the hot end can heat up to 450C.

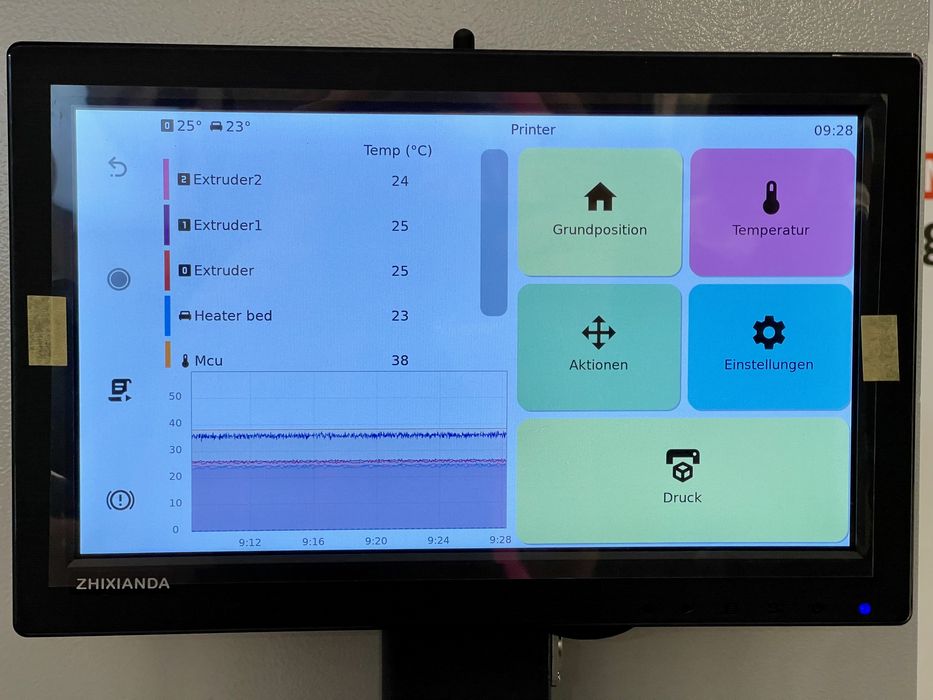

The machine is quite similar to a desktop FFF device, in spite of its enormous size. For example, it uses either PrusaSlicer or Simplify3D to prepare print jobs. For firmware, it runs Klipper, a current favorite in the desktop FFF world as it provides a means to achieve high speed 3D printing.

The 1800 leverages that capability completely by including an accelerometer. This sensor can be used by Klipper to calibrate vibrations, which can then be compensated for when printing at high speeds.

The print surface is simply an aluminum plate with magnetically attached surface. However, it can be heated to a whopping 120C. That, combined with the high hot end temperatures, means that this machine can likely handle a variety of engineering materials.

I asked about the cost of the 1800, and was told it was close to US$105,000. That’s quite a sum, but you can literally print furniture on it all day long.