How Italy’s Caracol is helping to spearhead the LFAM transformation of the marine industry.

From air, to land, to sea, additive manufacturing is helping to revolutionize virtually all forms of travel and transport. It’s today well known how the aerospace and automotive industries are utilizing the technology to accelerate product development and design new, more efficient parts. In fact, you’d be hard pressed to find a company within those sectors that doesn’t use 3D printing in some capacity. The uptake in the marine and maritime sectors has admittedly been a slower one, but we are now seeing just how transformative additive manufacturing can be thanks to a number of forward-thinking maritime players and AM companies.

Italian additive manufacturing specialist Caracol is one of the AM companies that is helping to pioneer marine 3D printing applications using its large-format 3D printing technology. As we’ll see in this article, the company’s large-format Heron AM system is enabling the industry to create more efficient, sustainable and customized structures for water vessels, including superyachts .

The Berth of Marine AM

In recent years, there has been a growing interest in the use of additive manufacturing for maritime and marine applications. On the industrial side of maritime, major players are exploring and using the technology for spare part production and structure repair. In this context, AM could accelerate maintenance for large ships and minimize down times for smoother logistics.

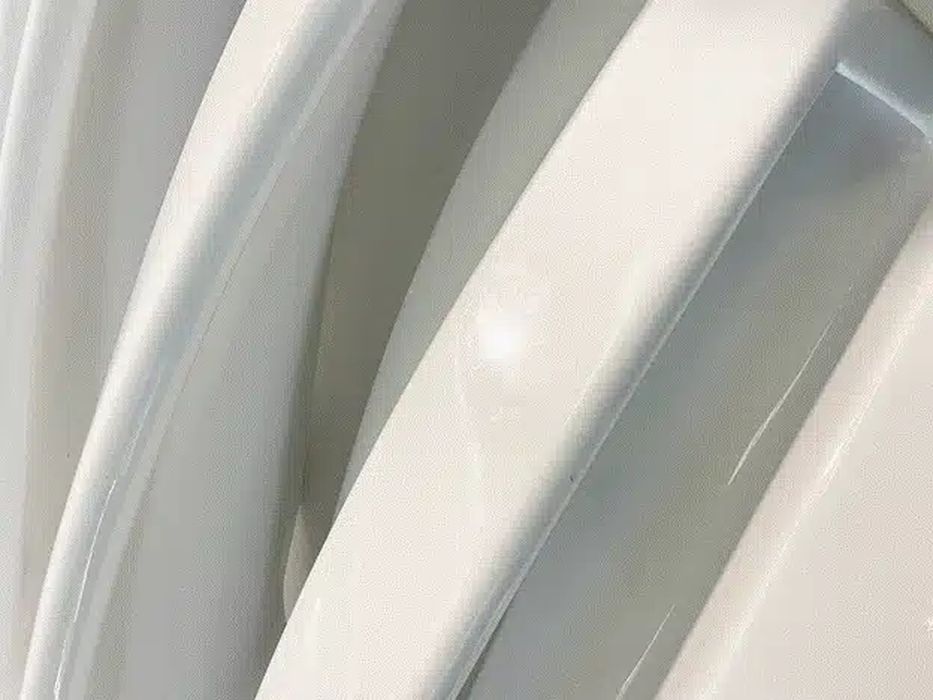

In the marine sector—encompassing sail boats, racings boats and yachts—there has also been enthusiastic adoption of 3D printing. In this space, we’ve seen several examples of AM being used to produce large-scale molds for yacht structures, as well as for the direct production of lightweight racing boat parts and customized yacht components, including large superstructures.

Interestingly, additive fits neatly alongside a number of other trends in the marine industry, such as the use of carbon fiber-reinforced polymers (CFRP), the exploration of more sustainable materials, and the use of more efficient energy systems, like hydrogen fuel cells. All of these trends are pushing the industry ahead in its mission to produce faster, higher performing watercrafts, as well as establish greater sustainability.

Why LFAM has a Leading Role

It’s no surprise that large-format additive manufacturing has—perhaps more than any other 3D printing technology—been critical to the advancement of marine AM applications. Boats, even small ones, require large structures and components, so the ability to print big is key. In addition to its sheer size, there are several other benefits to LFAM in the marine sector, such as the following:

- LFAM allows for the production of more complex components that are optimized for weight and performance.

- As an agile production process, LFAM enables part customization on a scalable, cost-efficient basis.

- Large assemblies can be consolidated into single-piece parts, reducing the amount of post-processing and assembly steps.

- LFAM accelerates production schedules by printing parts directly and eliminating the need for costly tools or molds.

- LFAM is compatible with a variety of durable, marine-ready materials, including more sustainable materials like recycled polypropylene with glass fiber reinforcement.

For these reasons, LFAM has been used for a range of marine applications, including the production of racing boat parts optimized for weight and speed, composite hulls (or hull molds), as well as customized luxury yacht structures designed to better meet client wishes. The technology is particularly well suited for these areas due to the small-batch nature of the production.

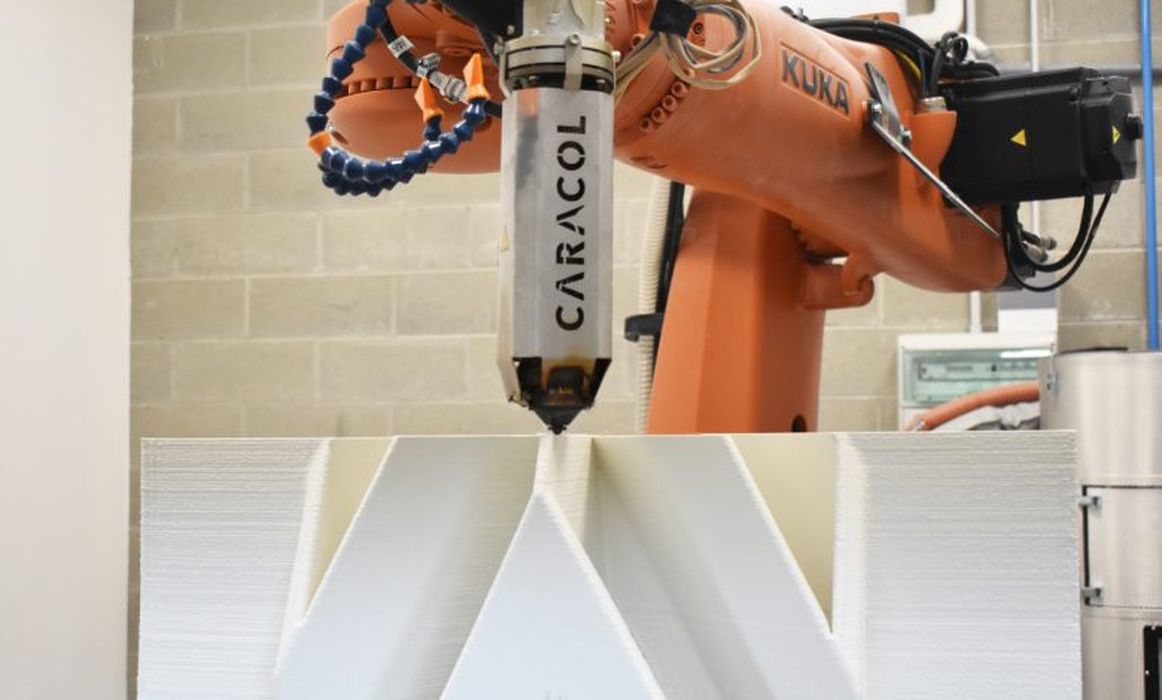

Amongst LFAM technologies, Caracol’s Heron AM platform has risen to the fore. Developed fully in-house by the Caracol team, the LFAM solution utilizes a 6-axis robotic arm fitted with a compact extruder. The system uses polymer or composite pellet materials, and is capable of depositing material precisely and rapidly to build large-scale structures. Notably, the Heron AM system is itself customizable, and can be configured to meet a range of different project requirements and shop environments.

The company’s Heron AM platform and its hardy materials, including recycled PP and ABS + CF or GF, have proven to be a successful combination for marine applications. To date, the technology has been used to produce large-scale marine components, including boat tooling, prototypes and end-use superstructures for a number of international enterprises as well as Tier 1 and Tier 2 OEMs.

Read the rest of this story at VoxelMatters