On May 25 and 26, 2021, Cimquest held its annual Xpand3D event, virtually.

R&D Tax Savers took a team approach to attending the event. The event opened on May 25th with Rob Hassold, Cimquest CEO, introducing Todd Grimm, Additive Manufacturing Consultant at T.A. Grimm & Associates, Inc, who provided an overview of the Additive Manufacturing (AM) industry and his thoughts on where the industry is headed. Grimm noted the biomedical and pharma industries were big this past year but focused more on what AM needs to be doing now in and in the next five to ten years, which it is currently not doing.

Here are some of our engineering team’s summaries of the sessions they attended. This is part one of two; please read part two here with insights into the future of CAD and how functional color is changing the game in additive manufacturing.

How to Select Your Company’s First 3D Scanner

Harry Foxman

Over the past three decades, scanning technology has advanced immensely. It is now a helpful tool to be used in reverse engineering, inspection, and 3D printing. With a large number of different types of scanners from a variety of manufacturers on the market today, it is important that a company selects the correct one. Before beginning the search for a scanner, companies should have predetermined criteria mapped out.

In order to narrow down the vast field of scanners on the market, there are several different steps to consider guiding you in the right direction. The first step is to determine what sizes of parts you want to scan. Are the parts large or small, mechanical or organic? For example, scanning a part to be used in a machine would require a drastically different scanner than scanning a feature on a body. The application of what is scanned also needs to be considered. An item can be scanned for a variety of reasons including reverse engineering, metrology, 3D printing, web content, and virtual reality. Additional software processing costs are also something that needs to be considered as scanners have specific software that they convey data through.

Accuracy and resolution are important aspects when determining what type of scanner. Accuracy in a scanner is how exact are the scanning measurements in a plus/minus sense compared to the actual object. Resolution refers to how well the scanner picks up fine detail in a part. Most scanners on the market have published resolutions. If accuracy is important for your application, make sure the scanner that is purchased has a published accuracy.

Repeatability is the ability of a scanner to repeat results when an item is scanned by a different person or a different technique. The deviation tolerances between repeated scans should be minimal. Color is another specification when considering what scanner to purchase for your company. Color can be a tricky aspect of scanning as sometimes a color scan can hide poor resolution. Texture needs to be turned off to reveal the poor resolution. In 3D printing, color is especially important when you have a color 3D printer and want to scan 3D parts in color.

The talk detailed a few specific scanners that they use. AutoScan Inspec has incredibly high accuracy and resolution. The EinScan HX handles low structured light scanning and laser scanning, and it has different specs for each. FreeScan UE X11 Laser Scanner can scan very shiny objects without have to put any type of covering on it. This scanner is extremely accurate. The C500 Structured Light Scanner is a stationary scanner with four different lens sets. It can handle very tiny parts to larger parts.

Optimize Your Manufacturing Process with High Efficiency Machining Training

Harry Foxman

This discussion examined the recent advancements in CNC tool path strategies. Understanding these advancements and how you can take advantage of them are key to growing your business. Sometimes the decision is difficult to purchase the equipment necessary for High Efficiency Machining (HEM). The discussion talks about the steps to prove and justify the purchasing of new equipment and training.

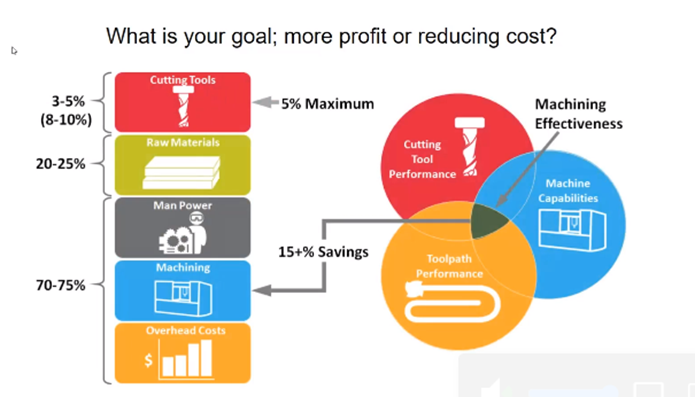

Increasing efficiency could mean a number of things including cycle reduction, cycle time reduction, or metal removal rate. You also need to address what your goal is. Is it increasing profit or reducing costs? Based on the chart above you can see the majority of profit increase and cost reduction opportunities come from overhead, machining, and manpower costs. Too often businesses try to make improvements to just the cutting tool and see limited saving results. It is a combination of improving toolpath performance, cutting tool performance, and machine capabilities that help your business achieve HEM.

When a new piece of equipment that could increase efficiency becomes available, there are several steps a company needs to take in order to justify the investment. There needs to be training and communication between the manufacturer of the machine, the owner, and the operator. Using Mastercam, perform an estimate of cycle time improvements and cost savings. If those time and cost savings are large enough to justify purchasing the machine, your company can now move on to implementing it. Implementation requires a lot of training and collaboration between programmers and operators. There can be damage done to the machine and tools, as well as minimal cost savings if the programmers and operators are not on the same page.

Some of the best CNC machines today for HEM involve dynamic motion toolpaths. Dynamic milling machines improve material removal rate while still maintaining process security. On average, dynamic milling machines reduce cycle time by 50%, and they have seen reductions of up to 82% from traditional toolpaths. These machines also increase machine and tool life.

Is Metal 3D Printing Ready for Primetime?

Joseph Castine

With the rapid expansion of the additive manufacturing industry, metal printing technologies continue to emerge, but this raises the question “Is Metal Printing Ready for Primetime?” The discussion by Nate Higgins (President, FreeFORM Technology), Ric Fulop (Founder/CEO, Desktop Metal), Bob Hedrick (President, CAMufacturing Solutions), Kenneth Fortier (Product Owner – Visualization and Simulation, Mastercam), and Rob Hassold (CEO/Founder, Cimquest) came together to discuss.

The metal segment is one of the fastest-growing of the additive manufacturing market, with some of the technology only recently becoming affordable. This is due largely in part to Desktop Metal, a company dedicated to making this growing technology more accessible for engineers, designers, and manufacturers. Desktop Metal went public at the end of 2020 with a valuation of $2.5 billion. Desktop Metal’s recent acquisitions include Adaptive 3D for elastomer and rubber materials and EnvisionTEC for photopolymer printers.

Within this industry, there are several metal additive manufacturing technologies emerging, including Binder Jet. Binder Jet is a technology that Desktop Metal has implemented in their Shop and Production Systems, since the printers use laser jet printing heads which can be found in paper printers around the globe, the systems can produce parts up to 100 times faster than that of their laser powder bed fusion counterparts. With the speed of this technology, it shows great promise for use in mass production scenarios, whereas many other metal additive technologies show greater promise in niche 3D printing applications.

These metal printing applications show great promise when used in series with traditional subtractive techniques such as CNC milling. At this point in the technology’s life cycle, the prints are not accurate down to 1/1000th, this is where the availability and existing knowledge base of CNC milling come into account. Using these technologies in series can allow for greater accuracy in dimensional tolerances accompanied by higher part output. Nate Higgins, the President at FreeFORM Technology, which was founded in November 2020 mentioned that with the use of Binder Jet the company has been able to send parts out the door just seven months into the company’s lifespan. Compared to traditional metal processes a seven-month period may represent the time required for the part tooling to be manufactured. Showing that if adopted correctly this metal printing technology can greatly decrease the wait times for part production.

Although metal additive manufacturing shows great promise there are some hurdles that need to be overcome before widespread adoption of the technology. As the technology is relatively new there still needs to be some standards and a larger gamut of usable materials. Nate Higgins added that in order for engineers to be able to design with this technology in mind there must be some material standards as well as a larger pool of materials as engineers cannot be constrained to use only a handful of materials. Additionally, Bob Hedrick asserted that the metallurgy of the materials needs to be constrained to ensure that the materials are robust enough to be used in their respective applications.

Overall, the group agreed that there does need to be some refinement of the processes and standards to ensure the efficacy of the technology. However, when asked the question “is metal printing ready for primetime?” the answer was a resounding yes. With Ric Fulop mentioning that depending on the specific application at this point the technology has an immensely bright future. The rest of the group echoed the sentiment that the adoption of this technology has obvious benefits and as the industry is projected to reach $100 billion by the end of the decade adopting now can propel you into the future.

This is part one of two; please read part two here with insights into the future of CAD and how functional color is changing the game in additive manufacturing.