Charles R. Goulding and Preeti Sulibhavi discuss one of LEGO’s newest product lines.

The Wall Street Journal recently featured an article that highlighted LEGO and its latest product line, “Dreamzzz.”

The world’s largest toy maker, with sales of US$9.2 billion (almost that of Hasbro and Mattel combined), is now competing with digital content in a formidable bid for children’s time. LEGO spent four years collecting feedback from about 30,000 children, globally, in their quest for the next greatest LEGO product line.

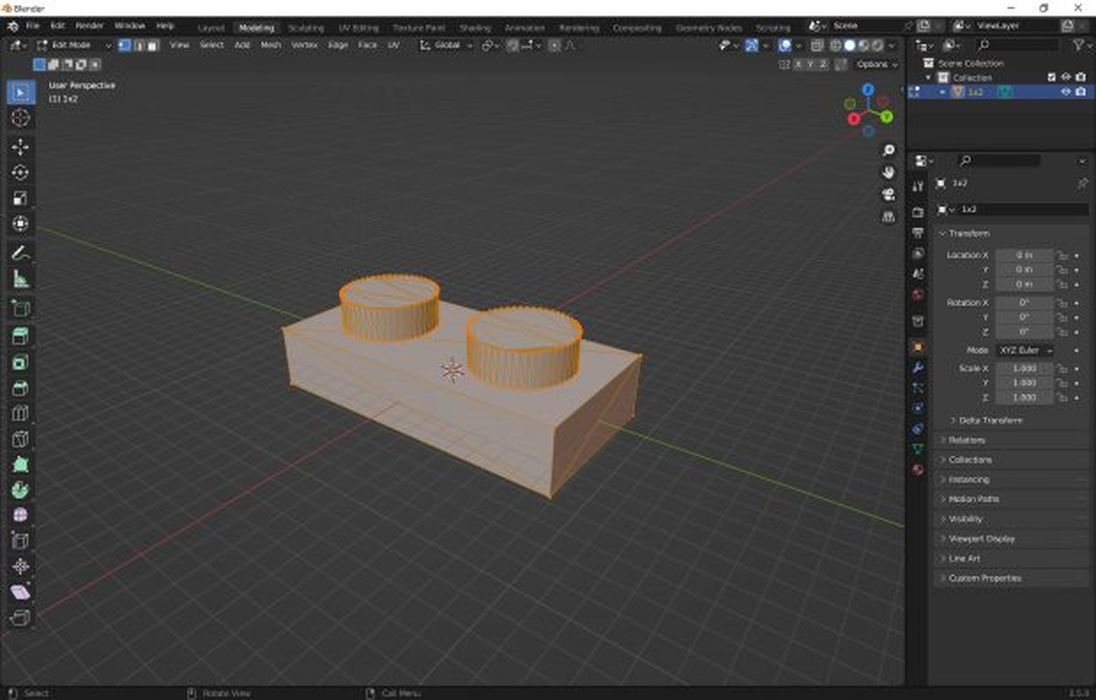

After an arduous development process, LEGO created their Dreamzzz product line with new shapes and animal heads (displaying distinctive features). To achieve this level of detail, successfully, LEGO used 3D printers.

There are other toys that involved 3D printers in developing them. We have covered Toybox, the 3D printer for kids as well.

LEGO has made a commitment to be more eco-friendly, as it has introduced various new products made from sustainable materials like plant-based plastic and recycled plastic. By 2030, the company hopes to replace all of its packaging with sustainably sourced materials.

LEGO uses 3D printers and 3D printing is not new to LEGO either. LEGO has used 3D printing in its research and development process to create prototypes and test new designs.

In 2019, LEGO released their first stand-alone 3D-printed piece, a duck. The 3D printed figurine had been included in a special edition set given to participants in the 2019 “LEGO Inside Tour” and could not be purchased directly. It did set the company on a more 3D printer-friendly path for its Dreamzzz product line.

Currently, LEGO’s manufacturing 3D printing sits alongside injection molding technology in the company’s manufacturing plants. Injection molding allows the company to make bricks at high speed and at a high quality. Meanwhile, newer technology offers support in product innovation and allows LEGO to make a greater variety of elements in smaller volumes.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Can LEGO Make Children’s “Dreamzzz” Come True?

With all the research and development that went into the Dreamzzz product line, all indicators lead to it being a success in terms of strong sales. However, it is a good thing that the current CEO, Niels Christiansen (formerly Danfoss’ CEO), is not afraid to discontinue unsuccessful product lines. Half of LEGO’s toys are discontinued and replaced with new ones, annually.

This means that LEGO needs to innovate and create new products at a pace that surpasses the products leaving their shelves. Industrywide toy sales declined for the third quarter in 2023. A successful Dreamzzz launch may result in a market share increase for LEGO.

With the help of 3D printers, LEGO can help make children’s “Dreamzzz” come true.