Leap71 has secured a major deal to provide their computational engineering services to the aerospace industry.

Fabbaloo readers may recall our six-part series on computational engineering, authored by Lyn Kayser, one of the founders of Leap71.

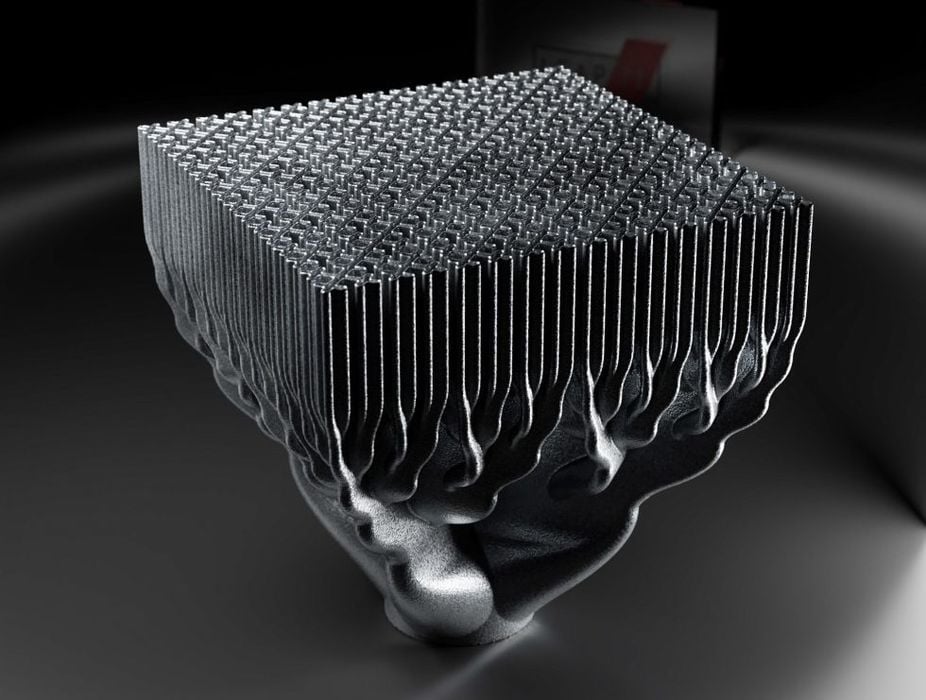

Computational Engineering is a new way to design highly complex 3D models. It’s not just another lattice generator, but instead uses engineering knowledge to create a kind of computational model. That model can then be tasked to quickly generate variants of a design based on inputs.

In other words, it can dramatically speed up the engineering and design process.

“CE” is so new few understand it, and even fewer have implemented it. That’s in spite of Leap71 open sourcing their PicoGK toolkit for developing computational engineering systems.

However, there’s now a major breakthrough. Leap71 has signed a deal with MIMO TECHNIK and ASTRO Test Lab to make heavy use of computational engineering in their aerospace and other projects.

The idea is that the three will develop a streamlined workflow for end-to-end product development. That will include design, manufacturing and part validation.

But who are the other partners?

MIMO TECHNIK is perhaps the leading metal 3D printing provider to the US aerospace and defense industries, currently operating a large farm of metal 3D printers to produce parts.

ASTRO Test Lab was the very first testing service dedicated to flight critical 3D printed parts.

Co-founder and Managing Director of LEAP 71 Josefine Lissner explained:

“Between the three parties, it’s pretty clear they have the skills to develop this workflow. Aerospace is a key focus for our company. Our computational systems can create sophisticated three-dimensional geometries based on encoded engineering principles and rooted in physics. However, we also need real-world manufacturing and testing feedback to continuously improve our models. By working with MIMO and ASTRO we can move to a truly collaborative workflow with a closed feedback loop, for the production and certification of very advanced systems.”

There are several important implications to this arrangement.

- First, it provides a way to much more rapidly develop highly sophisticated parts for aerospace.

- Second, it anchors computational engineering at the heart of US aerospace activity

- Third, it enables a significant growth step for Leap71, which might use this arrangement to generate further use of computational engineering in other areas.

For a long time I’ve thought that 3D printing has been held back by the limits and challenges with design software. It may be that computational engineering could help overcome that barrier and provide a path for 3D printing to become vastly larger than it is today.

Via Leap71, MIMO TECHNIK and ASTRO Test Lab