AML3D is an Australian startup producing large-format metal 3D printers.

The Adelaide-based company has been around for only a couple of years, but they’ve produced an impressive device that could generate many sales.

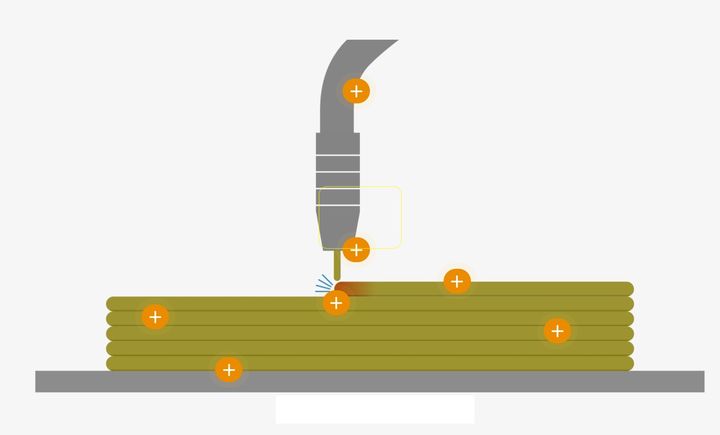

Their metal 3D printing process is not unique, as it is the familiar WAAM approach. WAAM, or Wire Arc Additive Manufacturing, has been around for several years. It involves pushing a metal wire through an electric arc to instantly melt the material. Yes, this is essentially a welding process, however the toolhead is moved in 3D space with a robotic arm, allowing the system to gradually build up material into a complete 3D object.

This video shows the process in action:

Curiously, AML3D calls their process “WAM”, or Wire Additive Manufacturing, but it’s really the same as WAAM as far as I can tell.

The AML3D system is called “Arcemy”, and it’s quite large. The company says it can be configured in a number of different patterns, as you can see in this video:

It’s possible to configure the Arcemy to different lengths, add secondary WAM toolheads and more. Because of this I suspect each Arcemy system will be custom built for clients.

The Arcemy system operates by depositing metal material on a metal sheet within the build chamber. The sheet is tied down during print operations, but is released and removed after printing completes.

After extraction, the print will have to be removed from the sheet, as is done in many metal 3D printing processes. AML3D doesn’t say, but this sounds like each Arcemy operator would also have to operate a wire EDM machine to cleanly slice off the prints.

AML3D provides their proprietary WAMSoft software tools with the Arcemy. This system management software can be used to prepare jobs for the Arcemy, and is able to handle a wide variety of metal materials that can be used on the wire arc toolhead.

The Arcemy device can also be used for welding, but it appears many of AML3D’s clients are focusing on the additive manufacturing capabilities.

As you might imagine, the surface quality of Arcemy 3D prints is pretty rough due to the nature of the coarse WAM process. However, that usually doesn’t matter when you are producing girder-sized objects. Function over appearance is the game with this type of device.

However, should an operator require smoother surfaces, they can be easily obtained by using a CNC milling device separate from the Arcemy. While there are some WAAM-style devices that include CNC tools within the 3D printer, that doesn’t seem to be the case with the Arcemy.

Who is the Arcemy for? It seems to be designed for industrial use, where low volumes of custom-designed metal parts must be produced. That suggests the market for AML3D equipment could be quite large worldwide, and that seems to be their plan.

One more thing: it turns out that AML3D is publicly traded on the Australian stock exchange. This means we’ll be adding AML3D to our list of biggest 3D printing companies in our weekly stock report.

Via AML3D