A French startup has developed an unusual food 3D printer, the Patiss3.

France is well-known for their amazing foods, and its thus no surprise that we see a food 3D printer emerge from Paris. La Pâtisserie Numérique (The Digital Patisserie), founded in 2019 by former Sculpteo Deputy CEO Marine Coré Baillais, has developed a printer that can produce dishes ready for baking, including pastries.

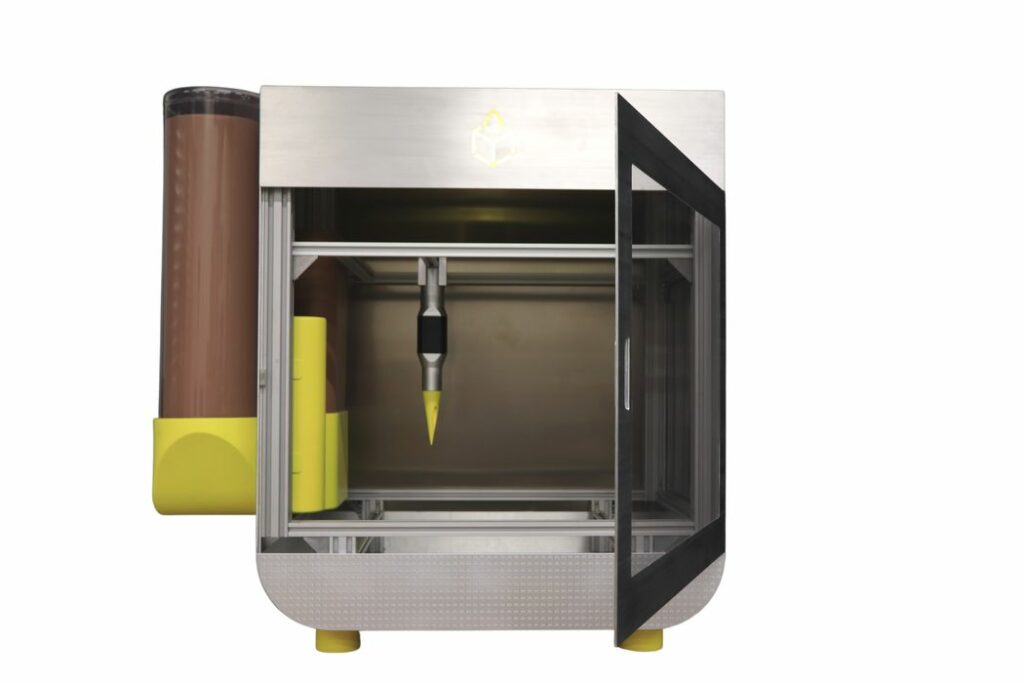

The Pattis3 follows the pattern of many previous food 3D printers in that it uses a cylinder of food material and a paste extruder, and is based on the company’s existing “Cakewalk” technology that can convert a typical 3D printer into a food 3D printer. The cartesian motion system allows deposition of material in desired patterns, layer by layer.

The difference with the Patiss3 is what happens next. The “build plate” for the device is actually a cooking pan. The idea is to take the completed print — still in the pan — directly to the oven for baking. This greatly simplifies the complications of trying to lift saggy dough from a print plate without disturbing its geometry.

Why build this? The company believes they can make life easier for pastry chefs, restaurants and industrial biscuit factories. The idea is that some pastries that have complex shapes can take considerable time to make using conventional methods, and with the Patiss3 they can be made automatically without much human intervention. That can also free up the pastry chef to do other tasks. La Pâtisserie Numérique believes they can “increase profitability by 26%” in such cases.

I have little doubt this device does work, but my questions are more about the software that drives the Patiss3. Pastry chefs are generally not known for their 3D CAD design skills, and there is a need to significantly assist them to create 3D pastry designs that are complex enough to warrant use of the machine.

It turns out that La Pâtisserie Numérique has indeed been considering this problem, and has developed a way to share designs. They explain:

“Aimed primarily at pastry chefs, restaurants and industrial biscuit factories, the Patiss3 printer includes a marketplace which can be accessed via an app. This catalog of 3D models features recipes from famous chefs. The app protects recipe creators and contributes to the payment of royalties for each culinary creation used via the app, allowing professionals to offer signature dishes.”

That is a very interesting concept, as it recognizes that likely very small percentage of pastry chefs will contribute original designs and therefore most Patiss3 operators will simply want to download existing designs, much like new 3D printer operators pull designs from Thingiverse.

La Pâtisserie Numérique also intends to open a “Foodlab”, where interested chefs can experiment and invent new dishes for the device.

You might be wondering about the materials used in the Patiss3, and it appears that it is up to the chef / operator. La Pâtisserie Numérique does provide some material recipes for their Cakewalk system, but they all seem to use standard food materials that are readily available.

The trick is tuning the device, as these random food materials certainly will have different physical characteristics, meaning print parameters such as flow rate, z-gap, layer sizes, infill percentages and much more must be determined.

This is an interesting food 3D printing concept that just might catch on, where other previous attempts have not.