Charles R. Goulding and Preeti Sulibhavi look at use of 3D printing in the bicycle industry.

The January 25, 2022, issue of the Financial Times included a piece about the Raleigh brand (owned by the Accell Group) agreeing to be bought by the U.S. private equity group, KKR for approximately US$1.8B in stock and cash. The Accell Group already has several leading bicycle manufacturers in their portfolio including, Raleigh, Haibike, Winora, Ghost, Batavus, Koga, Lapierre, Sparta, Babboe, and Carqon.

The hope is that the Netherlands becomes the bicycle center of the world, but as we have written on Fabbaloo before, there is intense competition from Portugal. The last major bicycle acquisition was when Adidas major shareholder, Groupe Bruxelles Lambert (GLB), took a controlling interest in the German company, Canyon Bicycles, near the end of 2020.

The bicycle industry is replete with examples of how 3D printing can be utilized, whether it is parts or accessories.

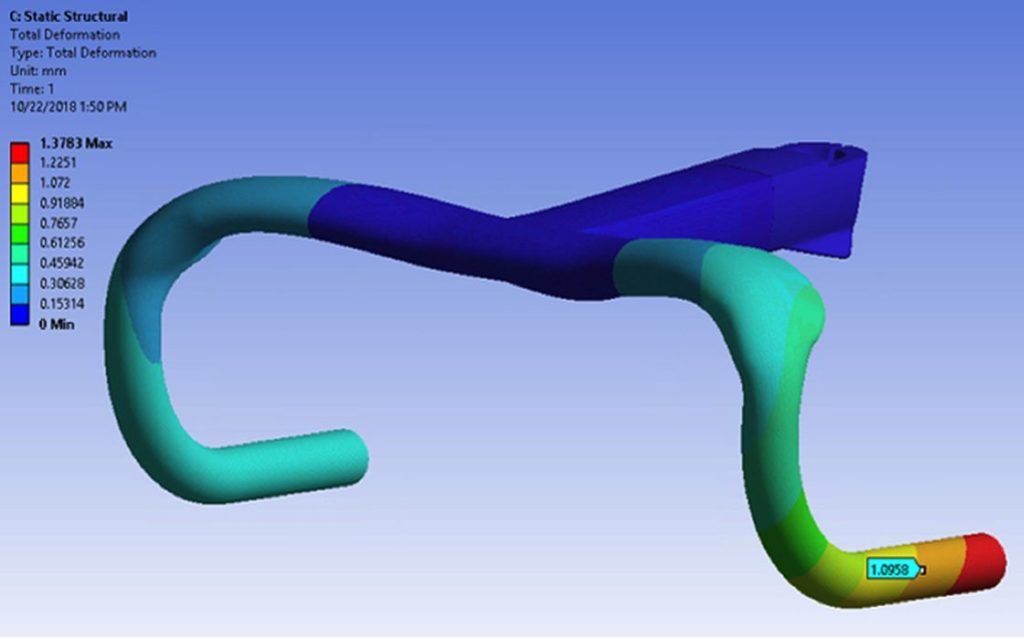

For the 2021 Olympics, bike manufacturers Koga and TU Delft designed and fabricated a bicycle frame and handlebars that were 3D printed and customized to the cyclist’s length and posture. 3D printing enabled the bike manufacturers to meet the targeted strength and stiffness by only adding carbon fibers according to calculated specifications.

But 3D printing is not just in the hands of industry bike giants. One man took to Reddit to explain how he managed to 3D print a bike bottle holder that would fit into the excessively wide bar of her Raleigh bike. He was unable to find one that would fit the Raleigh bike so he used STL and FreeCAD sources and he didn’t have to drill into the bike frame.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The Accell/Raleigh bike acquisition by a major private equity firm like KKR demonstrates that leading investors see great potential in the bike market. The 3D printing industry should continue to participate in helping to design and develop more customized, lightweight yet durable bicycle frames, parts and accessories.