Kings announced a new pellet-powered industrial 3D printer.

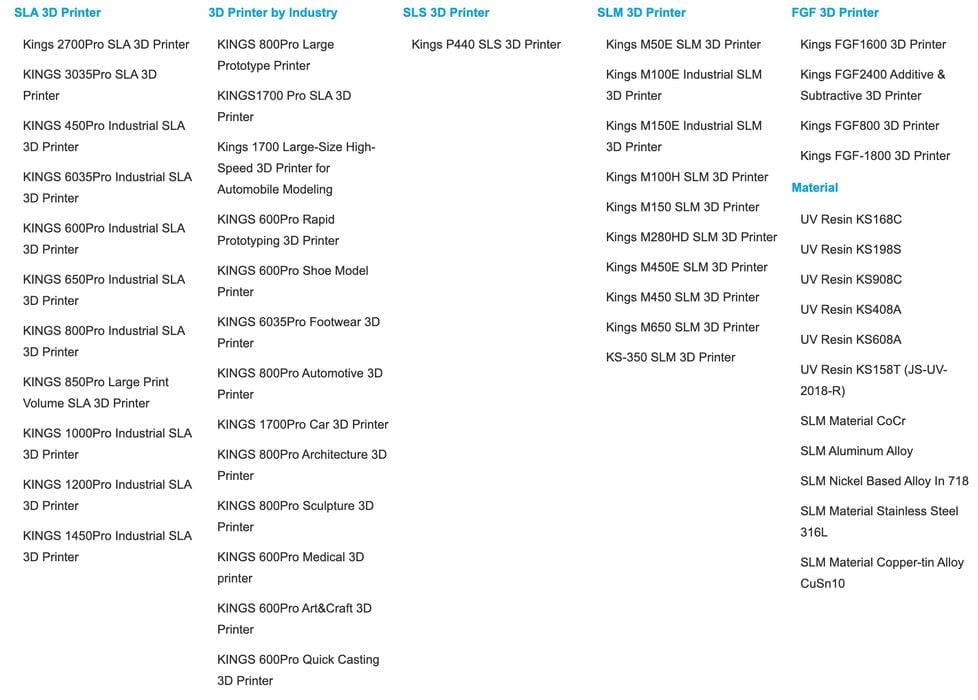

The Chinese company has been making industrial 3D printers for some time. They are not particularly well-known in the West, but they have the most incredible portfolio of equipment. Here is a list from their website of their current machine lineup:

Yes, there are no less than 28 different machines, and they happen to use four different 3D printing processes, including SLM, SLA, SLS and FGF.

“FGF”, or Fused Granulate Fabrication, is basically FFF, except that instead of a filament, the input material is in pellet form. Pellets are the raw material used to make filament, so FGF machine basically skip one step in the process and thus can be vastly less costly to operate. Gram for gram, pellets are much cheaper than filament.

The new 3D printer is the FGF800, and it uses the FGF process, if you didn’t notice from its product name.

The machine has a massive build volume of 800 x 600 x 800 mm, yet this is small compared to many of the other machines made by Kings. Their current largest machine is the 2700Pro SLA device, which boasts an enormous build volume of 2700 x 900 x 800 mm.

The FGF aspect is handled by a specially designed hopper system, which not only uses a pneumatic approach for driving pellets forward, but is also able to detect when the pellets run out. This avoids partial print failures.

There’s a large touchscreen to control the FGF800, and there’s the standard red emergency power off switch one always finds on industrial equipment.

Kings said there is also an optional high temperature version of the FGF800 if customers require to print materials such as PEEK, PEKK and ULTEM.

There are not that many pellet-style industrial 3D printers on the market, and it seems that Kings offers not just one, but four different models of various capacities.

Via Kings