Scientists have developed a method of 3D printing highly-desirable Wagyu beef.

If you’re of the carnivorous bent, you may have heard of Wagyu beef. Fewer will have actually sampled this incredible meat.

I happen to have done so on one occasion, and it was utterly unlike any beef I’d previously eaten. The meat quite literally melted in my mouth, and had an incredible beefy taste.

Why does this effect occur? It’s because Wagyu meat has marbling that’s a bit different from most meats. There is a huge amount of intra-muscular fat, which is of a type that melts at “mouth temperature”. This is why Wagyu meat is so desirable.

However, it’s hard to produce. Cattle have to be from a particular stock, and must undergo specific procedures to raise the animals. As a result, Wagyu meat is quite expensive. Wagyu originated in Japan, but today there are farmers who produce this type of product in other countries.

In the world of 3D printing, a pricey product is always attractive to the industry to offset the typically expensive process of 3D printing. While that rule usually applies to the mechanical part world, particularly in aerospace, here it might apply in the food industry.

Researchers at Osaka University — in Japan, no less — were able to produce a 3D printed Wagyu meat sample using bioprinting techniques. Specifically, they used a cultured meat approach, which we’ve described previously.

Their approach was to make use of two types of stem cells extracted from actual Wagyu cattle, from which they could culture all cell types necessary to produce the sample.

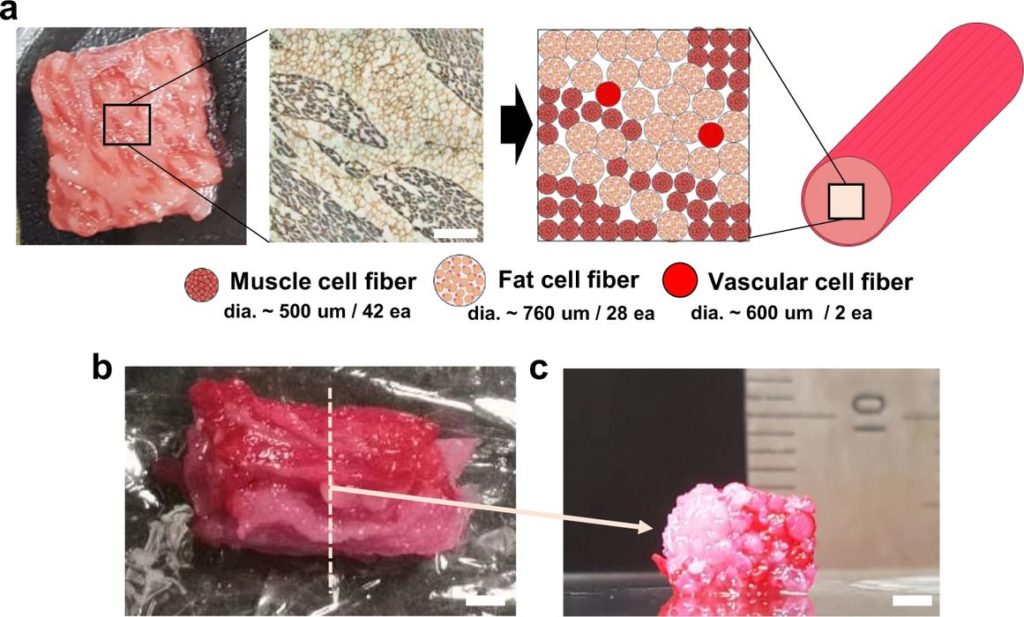

Once a supply of cells was obtained using lab cultures, the researchers were able to use them in a bio printer to 3D print “meat”. This is accomplished by 3D printing muscle fibers in strands to mimic actual meat, while filling in gaps with fat cells, along with other cell types as required.

They explain:

“We demonstrate in vitro construction of engineered steak-like tissue assembled of three types of bovine cell fibers (muscle, fat, and vessel). Because actual meat is an aligned assembly of the fibers connected to the tendon for the actions of contraction and relaxation, tendon-gel integrated bioprinting was developed to construct tendon-like gels. In this study, a total of 72 fibers comprising 42 muscles, 28 adipose tissues, and 2 blood capillaries were constructed by tendon-gel integrated bioprinting and manually assembled to fabricate steak-like meat with a diameter of 5 mm and a length of 10 mm inspired by a meat cut. The developed tendon-gel integrated bioprinting here could be a promising technology for the fabrication of the desired types of steak-like cultured meats.”

This is a notable development, as it could be an first step to commercializing cultured meat in a particular market.

While there are other ventures exploring 3D printed cultured meat, there may be challenges related to cost.

Successful entrepreneurs typically begin with a premium product, and then use the proceeds to develop successively less expensive products in later product generations.

Here we may have that “premium product” that would command higher prices for those seeking “perfect” Wagyu beef, particularly in areas where it is hard to find. I could imagine seeing Wagyu factories set up in regional locations, supplying meat distributors with premium cuts, all 3D printed.

But that’s just the financial dimension, and there’s more to the story here. Cultured meat approaches tend to be significantly more eco-friendly than traditional farming. They consume far less land, water, energy and produce much less CO2 than actual animals. This will also be an increasingly attractive property as time passes.

Will your next (or first) Wagyu steak be 3D printed? It may be, but not for several years.

Via EurekaAlert! and Nature