We have a quick update from JEOL on their metal 3D printing progress.

The Japanese company is relatively new to the Western scene, but it seems they are rapidly expanding. They seem to be leveraging their existing sales network, as the company was formed over 70 years ago in related industries. Specifically, their expertise in electron microscopes has been leveraged to make powerful metal 3D printers.

Their 3D printing process is similar to EBM, where an electron beam selectively melts a flat bed of metal powder. However, they’ve made some interesting tweaks to make their process quite a bit better than the standard EBM approach.

First, they’ve placed a transparent layer over the print bed. This allows the electron beam to pass through, but doesn’t let smoke and spatter go upwards and corrupt the cathode. This means the cathode has significantly longer life than typical EBM machines, making for lower maintenance costs.

Secondly, their process involves a “correction” step, in which the electron beam is more finely focused. This results in far higher quality prints from their equipment.

While they’re new to many outside of Japan, they’re now making moves in North America. JEOL has installed a system at Cumberland Additive, their first on the continent. Of note is that Cumberland Additive, a large print service, is AS9100D and ITAR certified, indicating that JEOL’s equipment is suitable for regulated environments.

JEOL representatives told us they have been strongly focusing on the aerospace market, and in particular the medical industry.

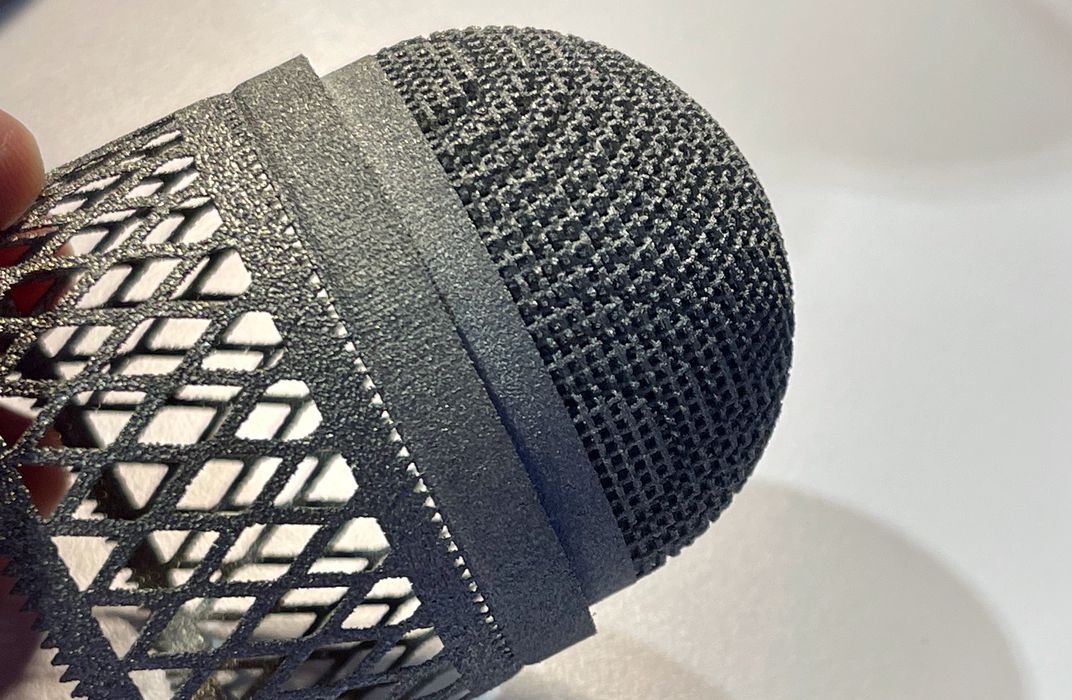

Here you can see print sample from their metal system. These “hipcups” are used as replacement hips. The fuzzy curved area is deliberately complex in order to encourage bone growth to permanently attach the hipcup.

JEOL’s system is able to rapidly produce volumes of hipcups, as you can see in this image of a stacked print job.

This is an ideal application for JEOL, as hipcups and other medical implants typically require these complex geometries, which are ideal to produce with the company’s high resolution EBM process.

One issue JEOL indicated is that they, like most 3D printer manufacturers, have to do a great deal of education of customers and prospect. There are still many manufacturers that have not yet adopted additive manufacturing practices, and those that do often require additional explanations of JEOL’s unique metal 3D printing process.

Via JEOL