This autobiography is a remarkable book and a must-read for those interested in innovation, design, manufacturing, and business.

Dyson is an unconventional thinker who takes products we accept as standard and completely re-invents them into an entirely new product category. This includes vacuum cleaners, fans, hairdryers and air purifiers. His quest for perfection is astonishingly evidenced by 5,127 interactions of the cyclonic cylinder vacuum cleaner in four years.

During his innovative process, he has revolutionized key components like miniature electric motors that power vacuum cleaners. Dyson has a formal art background which leads to beautiful design and functionality similar to Jony Ive, the great product and industrial designer who capped his commercial career as Apple’s chief designer and now is the Chancellor of the Royal College of Art.

Dyson uses his cumulative and extensive invention history to create his next iteration of products. Dyson spent decades facing formidable business challenges and he and his wife risked it all by financing his ventures with mortgages on their residence and facing economic hardship. Dyson explains how the major legacy vacuum cleaner manufacturers stopped innovating and opposed his bagless vacuums because their business model was based on selling replacement bags.

Dyson is highly critical of England’s traditional emphasis on class and lack of respect for engineering and manufacturing. Reluctantly, he has shifted a large part of his production and innovation centers to Singapore and the Philippines, where he has found the support for his company’s growth.

In 2006 the Dyson Airblade hand dryer went into production. In true Dyson fashion, there was no advanced market research but an intense focus on technology. The product uses a digital motor, touch-free infrared sensors, air moving at 430 miles per hour, HEPA filters and a carbon footprint six times less than paper towels. Like the vacuum cleaner bag industry Dyson has experienced aggressive pushback from the paper towel industry who still retains 90 percent of the hand drying market. Dyson has invented a leading hair dryer product after carefully studying the physical and chemical attributes of human hair.

In 2018, The Dyson Foundation awarded $500,000 to SUNY New Paltz to expand advanced manufacturing capabilities in the Hudson Valley. With the intent of transforming the manufacturing industry in the region, through a dramatic expansion of the Hudson Valley Advanced Manufacturing Center’s (HVAMC) ability to deliver high-value 3D printing for both prototypes and final-use parts to regional businesses, the grant will enable the HVAMC to purchase three distinct technologies and expand staffing to help Hudson Valley manufacturers take advantage of the Center’s new capabilities. These new additions will include an investment in a direct metal printer, produced by Desktop Metal, which fabricates metal parts and structures at a fraction of the production cost of previously available technology.

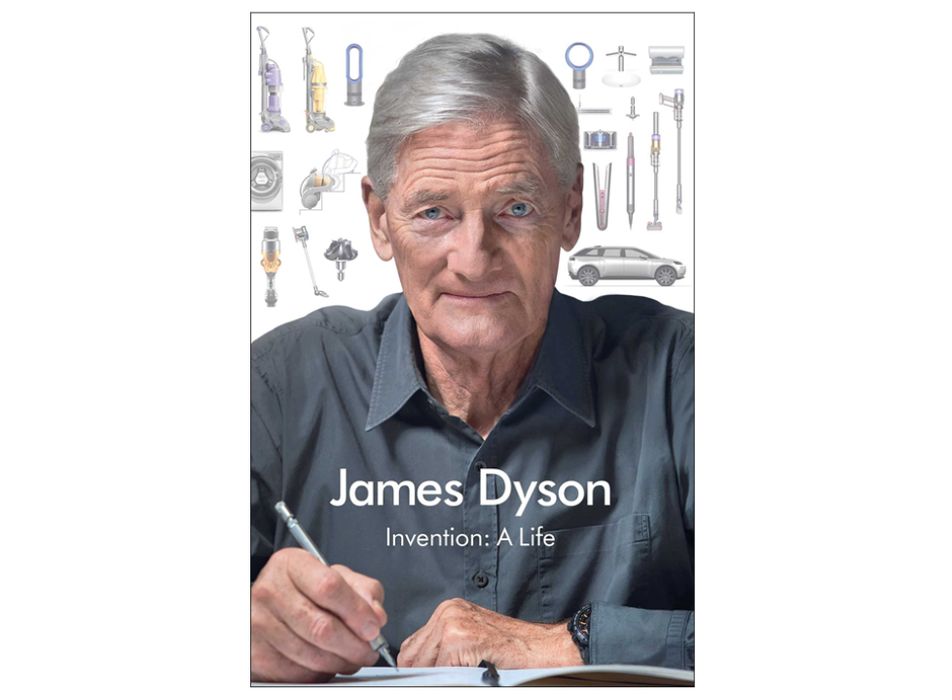

Like his products, Dyson’s writing style is simple, clear, and compelling. The book contains numerous product drawings, illustrating his and his engineering teams’ inventions. Dyson is highly critical of the patent system, which he feels is outdated and doesn’t protect the hard work of inventory from nefarious copying and infringement. I found Invention: A Life to be a page-turner that I couldn’t put down.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Sweeping the Competition

Like Dyson’s vacuum cleaners and other innovative products, Invention: A Life is a book like no other. I highly recommend to my colleagues, especially those in the engineering or design fields.