I had a chat with Jabil about their PK 5000 material.

Jabil is one of the most well-known contract manufacturers on the planet, and they use a great deal of 3D printing. So much so that they have their own materials. One of them is PK 5000 powder, used in SLS systems.

PK 5000 is based on PolyKetone, an unusual material in the 3D print space. It has an unusual production side effect, as Jabil explains:

“Our engineered powder, which is based on PolyKetone, is an eco-friendly and non-toxic polymer made from carbon monoxide and olefins. The ability to leverage carbon monoxide, which is a leading cause of atmospheric pollution, reduces its overall carbon footprint.”

The Jabil representative explained to us that they developed the material because alternatives were either too expensive, or were somehow compromised on one or more engineering properties. PK 5000 apparently resolves those challenges by providing a good mix of properties, but at a lower price point.

For example, it is chemically resistant, and at the same time provides high thermal properties. This makes it ideal for niche applications such as fuel tanks.

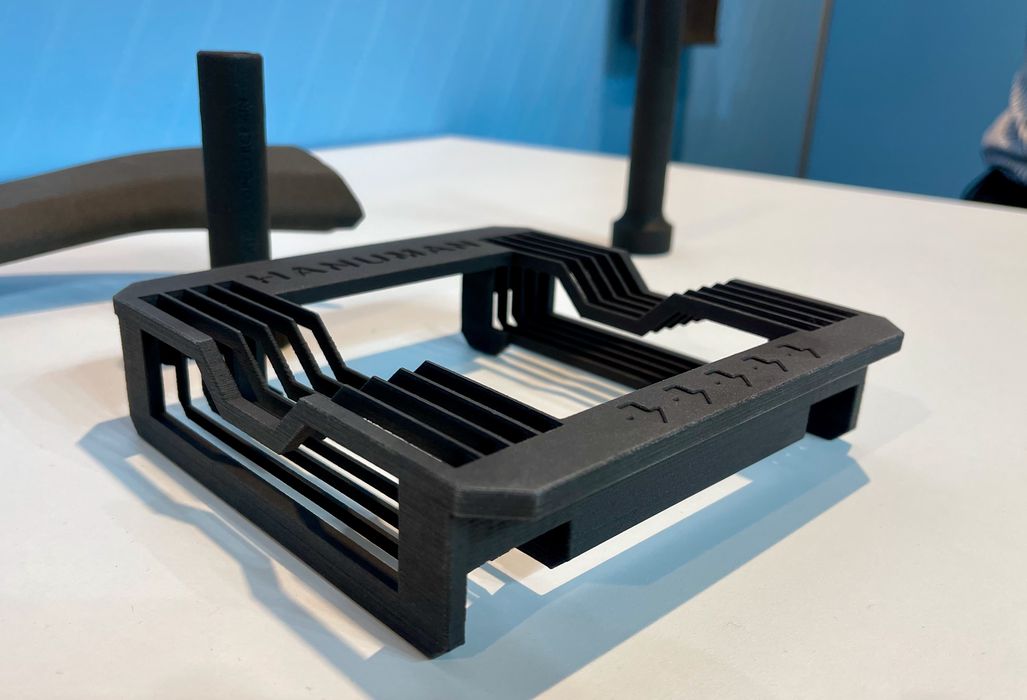

They’ve also used this material to produce safety equipment, such as this helmet.

What do they expect? They’re hoping customers will try the material and “like it”, the classic business strategy.

The combination of properties and cost should unlock more customer segments that would otherwise have not considered 3D printing as a solution for their applications, or at least that’s the Jabil’s hope.

Finally, there’s one personal note about this material: the representative said it “feels different”, and after handling some of the parts, I can say this is actually true. It does feel smoother than other materials I’ve encountered.

Via Jabil