I’ve become aware of at least one provider of apparently non-toxic 3D printer resins.

Toxic resin is the norm in resin 3D printers. The components in the resin are virtually always toxic, requiring 3D printer operators to wear protective gear when working with the resin.

This includes safety glasses, nitrile gloves, and sleeves to ensure skin does not come in contact with the resin. It also requires a very careful workflow, as prints move between printer, wash station and UV curing stations. Each step is a potential spot where resin can be mishandled and “dirty” surfaces or tools.

Honestly, a truly safe workflow is quite a burden and I am pretty sure that many resin 3D printer operators don’t always follow proper safety precautions. I’ve even seen videos where people freely pick up wet prints with bare hands.

The problem is that the toxins enter the body through the skin only gradually. Thus, after multiple exposures the body will sudden reach a threshold level and react. Thereafter, the exposed person will often develop symptoms whenever near resin, even from airborne smells. In other words, you don’t know it’s bad until it is. Therefore we’ve always strongly advised anyone operating a resin 3D printer to take all precautions.

All of this is caused by the toxic resins, which by the way are often totally safe AFTER they’ve been fully cured. Some are even food safe — after they’ve been cured.

I wondered if there was a non toxic resin that could be used to short circuit all these issues, and couldn’t find any.

The closest I could find were “water washable” resins. These are pretty much just as toxic, but they remove the additional issue of washing prints in similarly toxic IPA. Instead of IPA, you wash in water.

The problem with these solvents is that they become corrupted with, you guessed it, toxic resin. To “clean” them, you must leave the dirty solvents out in the sun, where the dissolved photopolymer resin will eventually cure and settle out. Water washable resin is slightly safer, but just as much trouble to use when you consider the entire workflow.

Then it was brought to my attention that there could be a truly safe 3D printer resin, made by, Carima, which just happens to be the oldest Korean 3D printer company.

They produce several different models of DLP-powered resin 3D printers, targeted at the dental, jewelry, ceramic and healthcare industries. Along with the hardware, they also provide a wide range of resins for specific applications.

Hidden in their list of resins is “Nontoxic CMYK” resin. They explain:

“Carima’s CMYK resin, consisting of five colors, is a non-toxic mixable material, allowing users to freely combine colors. The liquid resin has been tested and classified as non-irritant and no harmful chemical substances were detected, which makes it suitable for educational use and children’s toys.”

The emphasis is mine, and I point out the words, “liquid resin”. Not cured. Liquid. Non-toxic.

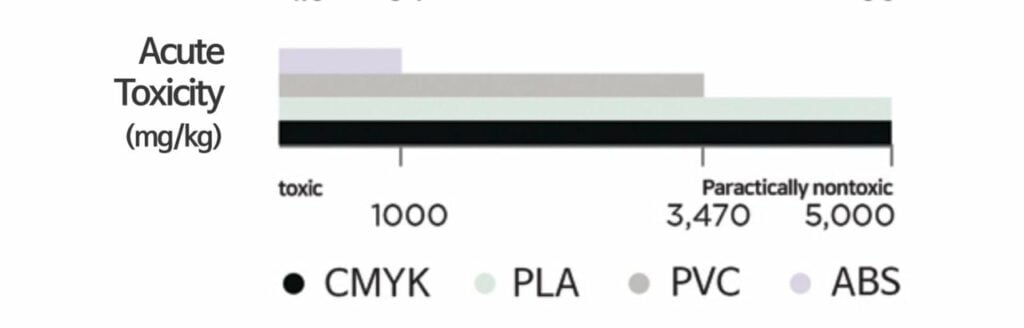

They provide this chart illustrating the toxicity, as measured in mg of toxic chemicals per kg:

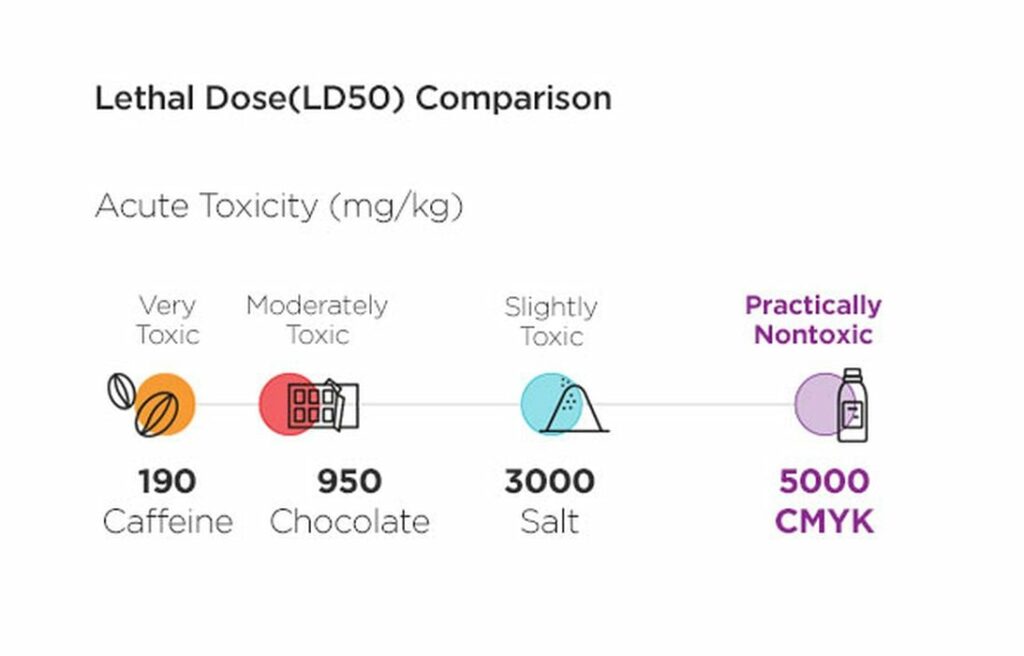

And this chart comparing the material to common substances that you would normally encounter:

You might be surprised that caffeine is so toxic. It’s so dangerous that years ago scientist Dr. Bernard Cohen challenged Ralph Nader to eat the same amount of caffeine as he would eat plutonium. The truth is all about HOW MUCH of the toxin is absorbed, and that’s what we’re talking about with the Carima resins.

However, the chart suggests that you’d need to absorb 26X as much volume of CMYK resin as caffeine to get a toxic dose, and many of you consume some amount of caffeine every day. I’m wondering where standard toxic resin would sit on this chart. [Aside: If you’re interested in the topic of common toxic substances, try searching for “banana radioactive” for a surprise.]

The resins have toxins, but so does everything else! It’s the level of toxicity that’s in question here.

As far as I can tell, these particular resins could be the least toxic one could use in a 3D printer that are commercially available.

But there’s more!

This family of non-toxic resins is actually intended for color mixing. The “CYMK” name is the standard color mixing method in the print industry: cyan, yellow, magenta, and black. With those four colors, it’s possible to reproduce any color you want, so long as you have the right mixing ratio. In the 3D print world, however, there is no “white paper background”, so the family also includes white and clear options.

Those six mixable resins should enable creative 3D printer operators to come up with very unique colors. You can even mix them “without stirring” to obtain wild multicolor resin 3D prints.

These resins are available for purchase from Carima resellers worldwide. I poked around and found a typical price to be about €60 per half liter, or about US$124 per kg. But remember, to get full color capability you need all six, and that would set you back about US$370 for a half liter of each.

I’m very curious about these resins and hope to give them a test in the near future.

Via Carima