3D printing is more involved than hitting Ctrl + P and grabbing a perfect part a few minutes later.

Between that printed part and the 3D model behind it is a 3D printing software, which dissects the model into printable slices and adds support structures when necessary.

But today’s 3D printing software goes far beyond conventional slicing. There are software tools that can automatically adjust the internal volume of parts, maximizing their strength and minimizing material usage. There are also tools that can intelligently modify the printing process, reducing part deformation.

Here’s some 3D printing software you should know about.

It’s What’s on the Inside That Counts

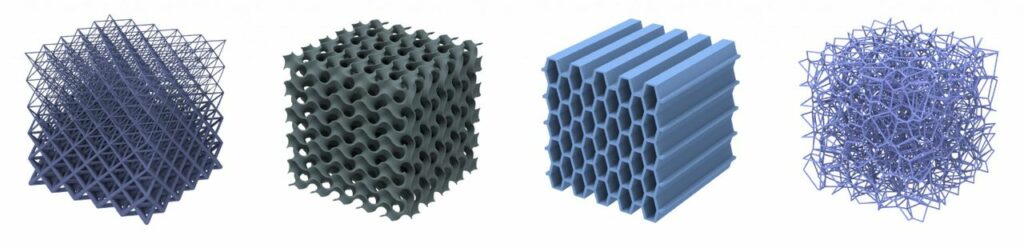

One of the most exciting applications of 3D printing software is the ability to optimize the internal volume of parts with lightweight lattices. Lattices can reduce part weight and material use while maintaining strength where needed. They can also maximize surface area (such as for heat exchangers), optimize geometry for energy absorption (such as for shock-absorbing helmets), and more.

While traditional CAD is ill-equipped for intricate lattice design, there are software tools that can automatically generate lattices for given geometries.

nTopology, for example, develops lattice generation software that can be tuned for function or aesthetics. The company’s eponymous software includes a library of lattice structures such as beams, honeycombs, stochastic lattices, and triply periodic minimal surfaces (TPMSs). Users import their 3D models into nTopology and automatically generate and adjust lattices to suit their requirements.

Lattices are a hot topic. Earlier this month, Altair acquired UK-based startup Gen3D, a developer of additive manufacturing software including Sulis Lattice for lattice generation. Like nTopology, Sulis Lattice allows users to automatically generate and fine-tune a variety of lattice structures for 3D printing. The lattice generation tool will soon be integrated into the Altair Inspire platform.

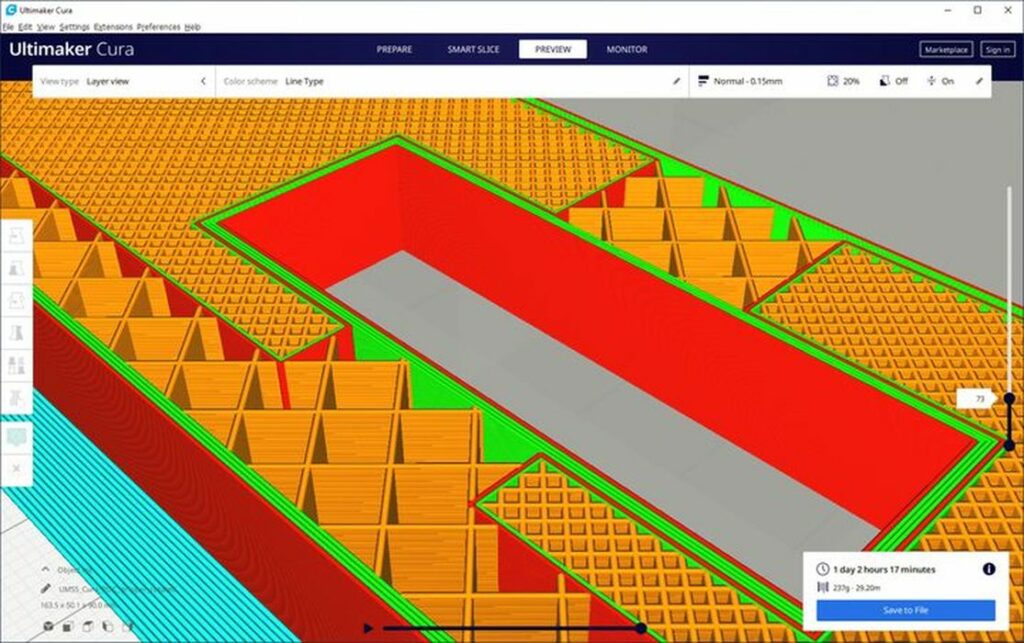

Another recent acquisition also centered on the internal volume of 3D-printed parts. In April 2022, 3D printing company Markforged acquired software developer Teton Simulation for its SmartSlice software, a cloud-based plug-in for existing slicing software. SmartSlice automatically adjusts the infill of parts based on a finite element analysis with user-specified loads. In so doing, the software aims to reduce the number of printed prototypes to save time and material.

Read more at ENGINEERING.com