There’s a rush to produce alt-meat, and it could be that 3D printing techniques could dominate the scene.

“Alt-meat” is a big deal these days, and much of it has to do with climate change. Researchers have determined that a significant component of atmospheric greenhouse gases are produced by agricultural animals. In addition, the expansion of agricultural operations in some countries has resulted in tearing down forests, thus releasing their carbon into the atmosphere and precluding future tree growth that would otherwise have soaked up CO2.

The proposition is that the amount of meat consumption should drop due to the heavy environmental load imposed by meat production.

Many vegetarians applaud this philosophy, but at the same time non-vegetarians really don’t want to abandon meat. In many cultures meat is an essential element in cuisine, and removing it abruptly simply isn’t an option that would be widely accepted.

Entrepreneurs have recognized this dilemma, and have sought solutions to provide alternative meat products that can be substituted, rather than trying to change food cultures that have persisted for literally thousands of years.

There are two approaches for producing alt-meat, but I believe both will end up with 3D printing aspects.

The first approach is to use an ingenious mix of plant material to duplicate the properties of meat. The second is to culture real animal cells in factory labs that don’t require actual animals.

Today it’s unclear which approach will eventually dominate, and it may be that both will exist in the future.

Regardless of the approach, both have a major challenge: replicating not only the nutrition of a meat, but its taste, thermal behaviors, mouth feel, robustness and safety.

Many of the alt-meat ventures try to skip around most of these challenges by starting with “hamburger”, a form where the meat has been ground up into much smaller pieces. This entirely avoids the texture problem.

The problem is that the “hamburger” approach won’t do for anything beyond ground meat because textures become vastly more complex and differentiated in real meat cuts. While today’s vegetarian-friendly buyers do purchase non-3D printed options, these products are not welcomed by carnivores aficionados because they are not “close enough” to actual meat. This means those options won’t be able to truly substitute for meat widely in most food cultures.

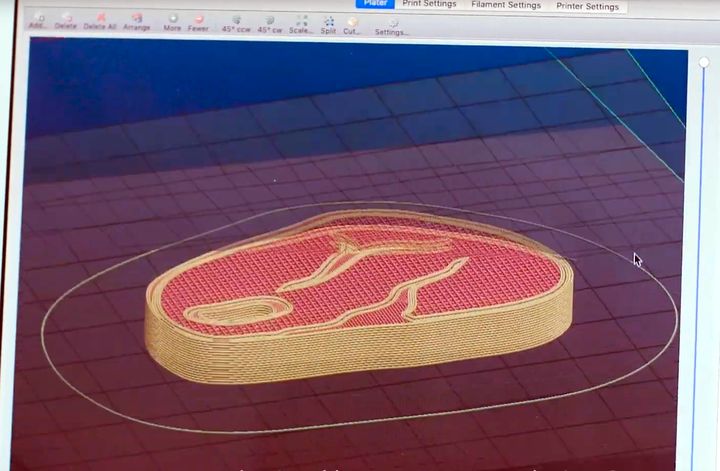

The solution, whether you’re using plant material or meat cells, is to build alt-meat cuts with a design in mind. Different types of material have to be deposited in patterns that create the necessary textures, and perhaps even thermal behaviors.

That sounds a lot like 3D printing, doesn’t it?

A 3D printing approach to alt-meat would allow meat designers to create cuts that mimic actual meat in terms of texture. A bit of fat here, tissue there, fibers aligned this way, etc.

This approach would benefit both the plant material companies and the animal cell companies, as they both need to create the necessary textures.

So far there seems to be only a few alt-meat companies using the 3D printing approach. Novameat and Redefine Meat are two that do so. I’m wondering whether the position of these and similar ventures in this area will eventually be more widely recognized. It could be that our future meat will be 3D printed.