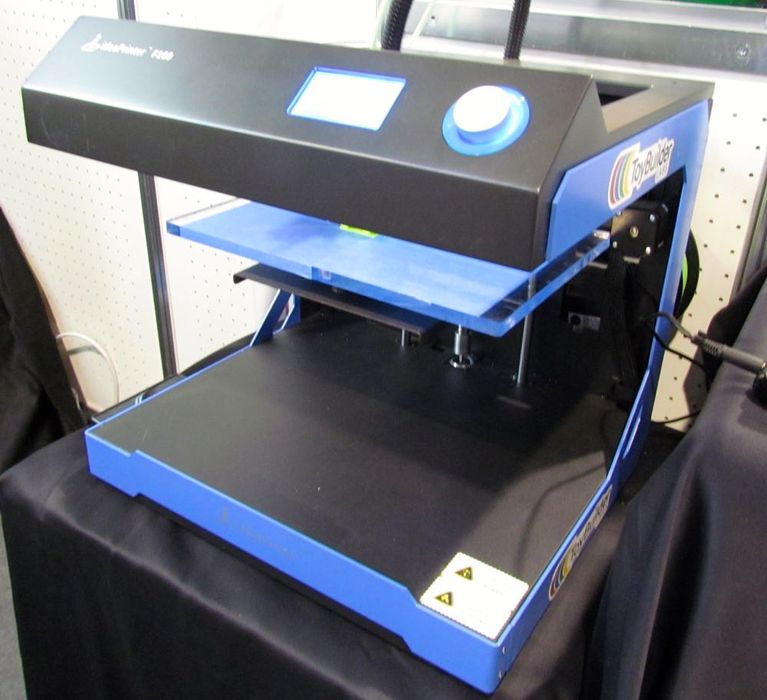

We have more thoughts on the question about the ancient F100 3D printer from earlier this week.

We received an enquiry from a reader that was stuck with a very old, but broken, ideaPrinter F100. Evidently static discharge pooched the controller board in the device, and the reader sought advice on how to bring it back to life.

My thoughts were a choice between these alternatives:

- Find a spare board somewhere (nearly impossible)

- Have someone try to fix the board itself (low probability of success)

- Just replace the machine

The latter option was recommended because even if the board was replaced, the rest of the machine remained in 2015 mode: poor printing characteristics, reliability, materials, bed adhesion and much more. It would be a lousy machine compared to today’s inexpensive equipment.

Thus I recommended giving up on the machine and just buying a new model, which would perform much better and might even cost less than the replacement board.

Then an interested reader suggested another alternative:

“I have to disagree with you with regards to the old 3D printer, the guy can buy a DUET electronic board and get his machine back to life, and it may even work better. If he does not have the skills to do the rewiring and confirmations there are plenty of technicians that can help.”

DUET is a UK-based company that produces well-regarded controller boards for 3D printers. Their boards are used in a variety of off-the-shelf machines and are quite popular.

They provide a variety of board options, with the current flagship model being the DUET 3. After some poking around, it seems that a good option might be the Duet 3 Mini 5+, which is available for around US$150.

This board provides a 32-bit processor, WiFi and Ethernet connectivity, silent stepper motor drivers, expansion capability, ports for up to two extruders. All of those are big upgrades to the F100.

The DUET system operates through a web interface, which is a bit complex at first, but covers all the bases. There is also a port for attaching a Raspberry Pi for a separate control panel interface, but that would add cost and complexity to the solution.

The reason I did not suggest this option was due to the F100 hardware. I’m the proud owner of several very old 3D printers that no longer work. I’ve considered putting new boards into them, but the hardware components are so old they likely aren’t supported by DUET. The same may be the case on the F100.

I don’t know the specifics of the hardware of the F100, but it might be necessary, for instance, to swap out all the stepper motors with current motors that have DUET support. I’m also not sure of the voltage used on the F100, which might be different as well. That could require a power supply replacement.

You see where this might lead. On one hand, it might be a simple matter of replacing the board (if it fits), but it might also lead to a chain reaction of replacement components and a long journey.

That’s all in addition to setting up the DUET so that its configuration matches the F100, which might be a bit of work to do. There will be some steps required to get it properly set up.

There are consultants that can do all this work, but they’ll also cost a bit of money.

If the original requestor has the technical chops to undertake that work, it might be possible to get the F100 working — but it really wouldn’t be an F100 anymore.

Even after all that, you’re still using a machine that doesn’t have a heated print surface, so that should likely be replaced as well. The DUET board can easily connect to it and provide energy for heating.

In the end I think it would still be a lot simpler (and cheaper) to just buy a new desktop machine for US$200-300, which would be pretty close to the cost of doing the DUET upgrade.

Are there any other approaches possible?