3D in Auto Repair Task Force issues final report on the promises and challenges of 3D-printed replacement parts.

Just picture it:

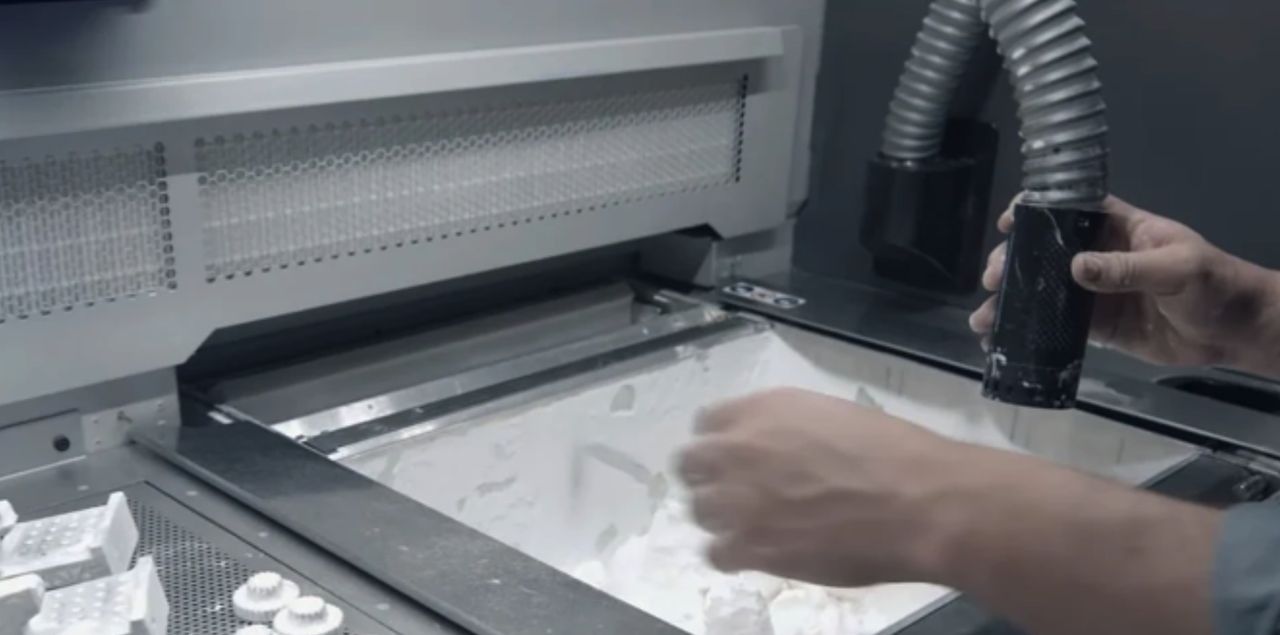

You walk into an auto parts shop, and instead of shelves packed with inventory, you see banks of 3D printers waiting to produce any part for any make and model.

It’s a car lover’s dream, but could it become a reality?

That’s the subject of a recent report by the 3D Printing in Auto Repair Task Force, a group composed of automotive and additive manufacturing (AM) experts who came together to evaluate the potential of using 3D printing technology for automotive repair.

“3D printing exhibits transformative potential in the collision industry,” reads the report, “especially in manufacturing smaller short-run plastic components, in favor of traditional large-volume injection molding manufacturing. In addition, items like repair kits for headlights, sensor cradles for bumper covers, and high-value clips are very favorable for 3D printing applications.”

The report identifies several other promising areas for 3D printing in this space, including discontinued or out-of-stock parts that would typically require high-volume production, as well as attachment-style repair kits that cannot be purchased through existing supply chains.

Balancing risk and reward, the report also cautions against the potential for “an influx of substandard, unregulated parts from unverified or unlicensed sources,” which could flood the market and undermine confidence in 3D printing technology, in addition to posing safety concerns.

When it comes to the benefits of using 3D-printed parts for repair, the report ticks off the usual AM checklist: reduced inventories, lower costs and more sustainable business practices. That goes for OEMs, collision shops and car owners, but there are also insurance companies, which could save money on rental costs thanks to faster turnaround times for vehicle repairs. Everybody wins.

Read the rest of this story at ENGINEERING.com