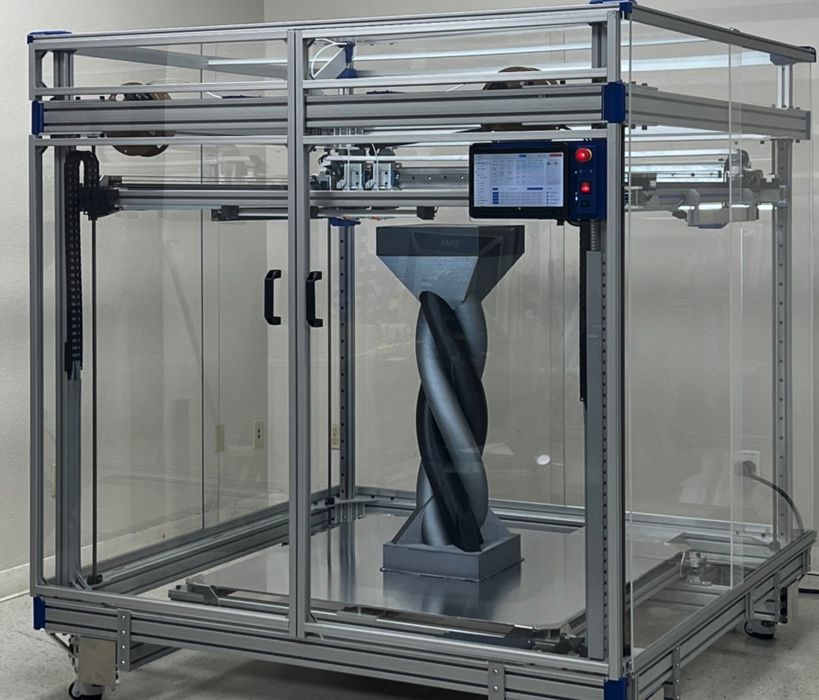

Let’s take a look at the surprising large-scale 3D printer from Syndaver, Apogee.

You may not have heard of Syndaver, as they are one of the more mysterious companies in the 3D print space. If you look online, you’ll quickly realize Syndaver appears to be a company that produces high quality synthetic cadaver models, with no mention of 3D printers.

They are a Florida based company, and they established “Syndaver West” back in 2020 by scooping up a number of experienced 3D printer techs previously from LulzBot, which had then abruptly changed ownership and moved to Fargo.

Syndaver West’s first 3D printer is the Axi, announced in 2020. It’s a desktop FFF device with an open gantry design. The design is extremely similar to LulzBot’s equipment, which is unsurprising due to the company’s history and the open source design files.

We hadn’t heard much from Syndaver regarding new 3D printers for quite some time. Indeed, it’s actually quite tricky to find out anything about Syndaver West online, as the Axi, for example, seems to only show up at reseller sites.

Suddenly there’s the appearance of a new Syndaver 3D printer, the Apogee. This machine is utterly different from the Axi and about as far from LulzBot designs as you could imagine.

The Apogee is still a polymer device, but it’s designed to 3D print large-scale objects. Visually it appears similar to BigRep equipment, and is definitely not a desktop machine.

There doesn’t seem to be any information online from Syndaver regarding this device, which is quite unusual for a manufacturer. However, we were supplied some details by one of their resellers, IT-Works 3D. CEO Zach Ruder’s company is currently selling the Apogee to the public.

Let’s look at the Apogee’s specifications first.

The build volume is massive at a whopping 1000 x 1000 x 1000 mm, making this one of the largest FFF devices available with few competitors at this size.

The Apogee is an enclosed device to maintain a consistent thermal environment during the presumably long duration print jobs that take place on the platform.

The print surface is made of aluminum, and can be heated up to 120C. This is the major source of heat for the enclosed chamber. There’s an optional active filtration system on the enclosure that’s said to remove VOCs and nanoparticles.

The enclosure is composed of perfectly transparent panels, allowing for a full 360-degree view of ongoing operations. The Apogee also includes “stage lighting” that can assist in viewing the print in progress.

Syndaver has engineered the Apogee to be able to handle a wide variety of common engineering materials, including PLA, ABS, PET-G, PA, PC, TPU, glass or CF-reinforced materials and others.

There’s full network connectivity on the Apogee, and you can use a variety of commonly available slicing software tools to prepare jobs for the machine.

This is partly accomplished with the use of an E3D Revo swappable hot end system. The Revo is a sophisticated component that offers easy switching of nozzle diameters between 0.4 – 1.4mm. The wide nozzles will be of particular interest for large-sized prints on the Apogee, as they could potentially speed up the print duration considerably.

Note that I termed the Apogee a “polymer” device. While the standard model is a FFF device accepting filament, it also can be modified to accept standard polymer pellets. It adds a large hopper with appropriate pellet feed mechanisms to deliver a stream of pellets to the hot end.

The pellet option could be quite desirable on the Apogee, as the cost of pellets is very significantly less than the equivalent weight of filament. For large prints this would result is considerable savings.

As you can see by now, this is quite a different machine when compared to the Axi. It seems that Syndaver is heading in a different direction than they initially appeared. That’s likely a good move because the large-format 3D printer space has been quite profitable for the few companies operating there.

However, it’s still a competitive market, and time will tell if Syndaver’s pricing and support are sufficient to attract buyers away from other large-format options.

Via IT-Works 3D