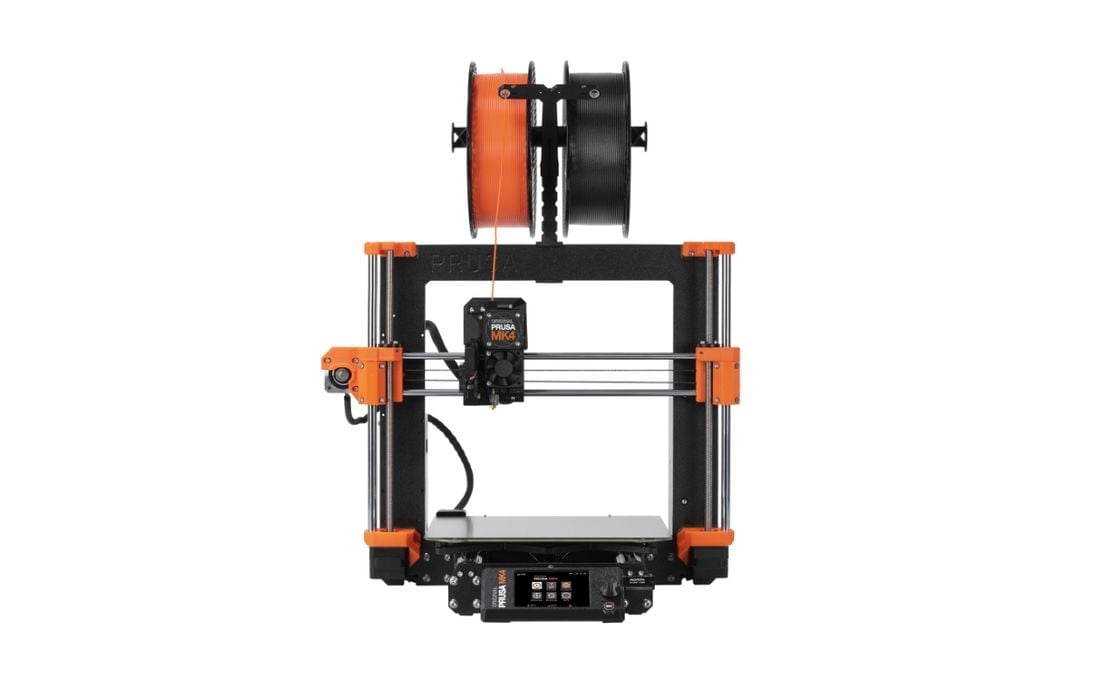

Surprise, surprise! Prusa Research has suddenly announced the Original Prusa MK4 3D printer.

No, it is not April Fool’s day. The long fabled device is set to assume the role of flagship device for the Czech company that has run with the MK3 platform for over five years. The MK4 is overdue, but now it is apparently ready for immediate shipment.

In a very long post, Prusa Research CEO Josef Prusa explained the key features of the new MK4:

“It’s built around our new 32bit connected architecture, it has the next-generation extruder (Nextruder), it lays down a perfectly smooth first layer every time without Live Adjust Z and it has support for high-speed printing with Input Shaper and Pressure Advance. We also improved the safety features even further. Plus, there are a ton of useful things, such as quick-swap nozzles, built-in support for remote printing and webcams, and many more. And it’s still beautifully quiet.”

My initial thought is that the MK4 is inheriting not only features from the MK3, but also from the Prusa XL professional 3D printer that was recently shipped, such as the Nextruder and 32-bit architecture. However, at the same time, Prusa said “90% of the parts” have been replaced in the new MK4.

Other improvements include:

- A stiffer frame and thicker Z-axis rods that are “vibration dampening”, and this is especially important for higher-speed 3D printing

- Network connectivity through either WiFi or wired Ethernet

- Full color screen

- A curious new light bar below the screen to visually identify current machine status

- Quick-swap nozzles

- V6 nozzle adaptor for using third-party nozzles

- Literally no calibration required as both leveling and Z-axis configurations are automated

- Magnetic filament-out sensor

- USB-C interface

- Power loss job recovery

- Slightly increased build volume to 250 x 210 x 220 mm

The Nextruder’s gear is vastly larger than typical extruder gears, meaning it will have considerably more “bite” on filaments. This should lead to far less slippage and more consistent printing.

Alas, the MK4 still does NOT have a touch screen. Instead the color screen is operated by the traditional rotary knob. It looks like quite a nice knob, however.

Prusa Research’s video shows a typical print that would have taken ten hours on a MK3 device can be 3D printed on the MK4 in only 3.5 hours. This is a result of the input shaping feature and vibration dampening frame, and likely provides a 2-3X speed improvement on prints. They can apparently 3D print a #3DBenchy in only 20 minutes!

The MK4 can be operated remotely using the network connection using Prusa Connect, and this is now using an encrypted data flow for added security.

Prusa Research has included several new sensors to provide added safety and most likely a reduction in problems and maintenance:

- Heatbreak thermistor, which should prevent major clogs

- Hardware overheat detection

- Overcurrent protection

- Dual voltage monitoring

These are unique and definitely will improve the safety and maintainability of the MK4.

The control panel now offers the ability to do “one click printing”, which appears to be a way to interface directly with the company’s Printables online 3D model repository. There is also a way to trigger preprints of previously printed files. This could be quite useful for those using the MK4 for low volume production.

An interesting feature I want to learn more about is the use of “Non Vertical Feature Artifact” motors, which seem to reduce patterns on printed vertical surfaces.

A slight timesaving new feature is that the pre-job mesh bed leveling inspection can now take place only on the area that is actually to be used in the forthcoming print job. This avoids the relatively slow process of checking out the whole bed.

There are a slew of other features, but you’ll have to read through all the documentation to see them. It’s pretty clear that Prusa Research has been working on this device for a long time, and they even say the design has been tested for one million hours.

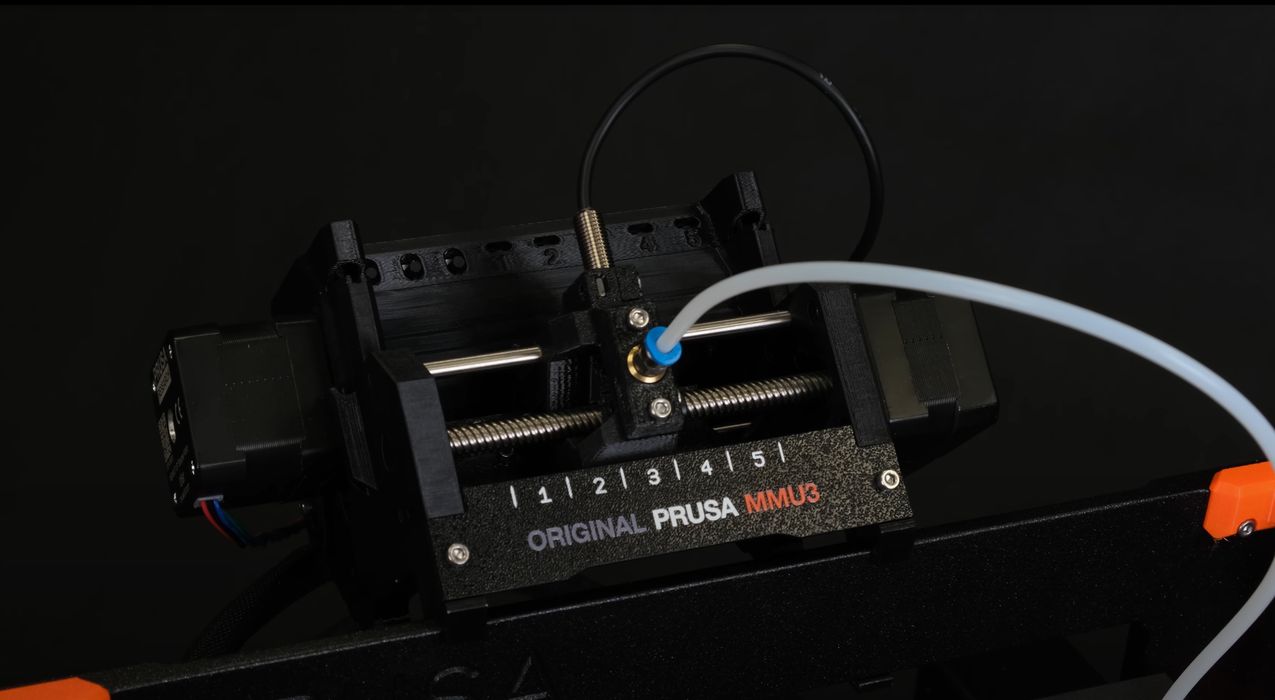

Simultaneously, the company also announced a new MMU3 to replace the very challenging MMU2 multimaterial accessory. This attachment enables the use of up to five different filaments in the same print job. They say:

“The MMU3 is MORE RELIABLE and easier to use”

That’s good; the MMU2 was extraordinarily difficult to use, and I — and many others — have basically given up on it. I’m really curious to see how the MMU3 works and what Prusa Research has done to make it more reliable.

Surprisingly, the MK4 is available now! Prusa Research apparently has a few hundred units ready to go, but I suspect they will clear out very quickly and a waitlist will emerge.

The price of the machine is much the same as the MK3S+, US$799 for the kit, and US$1099 for an assembled version. They are also offering those who order the much larger and more expensive XL device to switch to a MK4 unit.

There are also three different upgrade options for taking a MK3S+ to MK4 territory. There is a full upgrade that costs almost as much as a new MK4 kit, but less expensive options that provide some of the new functionality.

I’ll have more thoughts on this announcement after I digest it all — there is an enormous amount of information provided by Prusa Research for their new flagship product, the Original Prusa MK4.

Via Prusa Research (Announcement) and Prusa Research (Product) (Hat tip to Morgan)

The MK4 comes with a touch screen. It’s just not enabled in the firmware – yet.

Also: I hate touch screens.

thanks for the article