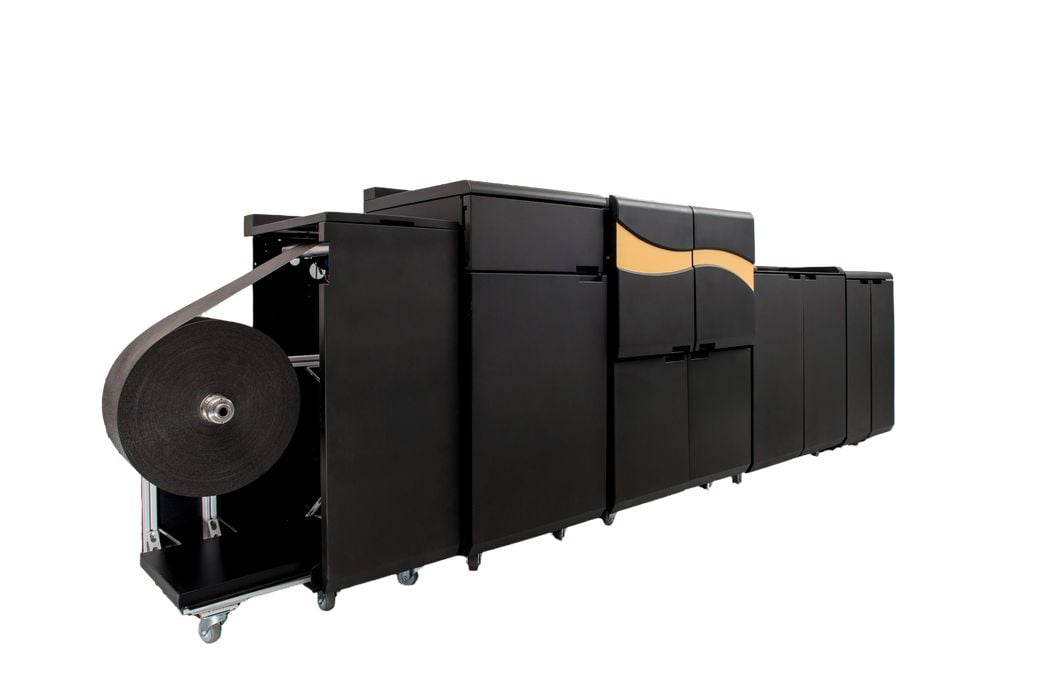

Impossible Objects has announced a new 3D printer, the CBAM 25, which prints at an incredible speed.

The Illinois-based company has been developing its unique sheet-based “CBAM” system for around ten years now, and it seems they’ve managed to fine-tune it for rapid production.

CBAM is a process unlike any in the 3D print space, as it uses sheets of material rather than powder, resin, or filament. We took a look at CBAM a few years ago, but here is a summary of how it works:

The CBAM Process Explained

- A standard sheet of, say, carbon fiber material is laid down in the build chamber

- A high-resolution inkjet system selectively drops a special aqueous solution (mostly water) on the sheet

- The entire sheet is swiftly covered in a powder; some powder sticks because of the fluid

- A second sheet is placed on top of the first sheet

- Registration holes are cut into the sheet

- This repeats, layer by layer, sheet by sheet, until the object is complete

- The entire stack, with a shaft through the registration holes, is removed

- The stack of sheets, still bound by the registration holes, is placed in a powerful heat press

- The heat press bakes the carbon fiber sheets together in the same manner as is done in non-3D printing applications

- The baked stack is removed from the heat press and excess, non-adhering pieces are cut off, yielding the final object

The CBAM process is able to quickly produce very high-strength objects due to the embedded composite materials, often being carbon fiber or similar.

Increased Speed and Production Applications

It’s not clear what the company did to increase the print speed or even the updated speed specifications. However, they believe the new CBAM 25 has sufficient throughput for production applications. In fact, the company’s chair believes the CBAM 25 to be the “World’s fastest 3D printer.”

Impossible Object’s CEO Steve Hoover explains:

“With a fifteen times speed improvement over existing 3D printers, our new CBAM 25 completes the transition of 3D printing from its roots in prototyping to the heartland of manufacturing. It’s hard to actually imagine what fifteen times faster means. For a comparison, this is also the speed difference between the fastest human running the mile and a Formula race car in a straightaway. That’s the same difference that our new CBAM 25 has versus prior technologies. We believe that this is a huge step forward not only for our company but also our industry, as it moves 3D printing into volume manufacturing.”

One of the materials being used in the CBAM 25 is carbon fiber PEEK sheets, which should enable the production of not only strong objects but also parts resistant to heat and chemical corrosion.

Impossible Objects believes many of the parts that can be produced on CBAM equipment can be used as substitutes for certain metal parts in specific applications. These parts could also be far lighter in weight than their metal counterparts, making it more advantageous to use them.

We’re interested to learn more about how the CBAM 25 achieves these higher print speeds.