SprutCAM’s P3D slicer offers full robotic 6-axis slicing of 3D models.

SprutCAM is a software developer that produces a CAM (Computer Aided Manufacturing) tools for manufacturing, specifically for multi-axis robotic systems.

Robotic systems are rarely seen in the world of 3D printing because they are vastly more complex than the relatively simple “cartesian world” in which most 3D printers exist.

For cartesian systems, the slicing software logic that drives the motion system is quite straightforward:

- Cut the 3D model into layers of uniform thickness

- For each layer identify the outline of the object

- Generate a 2D path for that perimeter

- Generate a fill pattern for inside the perimeter

- Raise the platform by the layer height

- Repeat

That’s it. That’s the core of every cartesian 3D printer slicing software that’s ever been written. It’s not even 3D; it’s actually 2D, but with stacked layers.

But controlling a robot is far more complex. You really have to manage the 3D environment. In fact, it’s even worse as robots typically have 5 or 6 axes of motion: 6D.

As the robot moves about in 3D space it runs a significant risk of collision with the print that’s taking place. The print could be any geometry, while in the cartesian world the layer approach guarantees collisions will never happen.

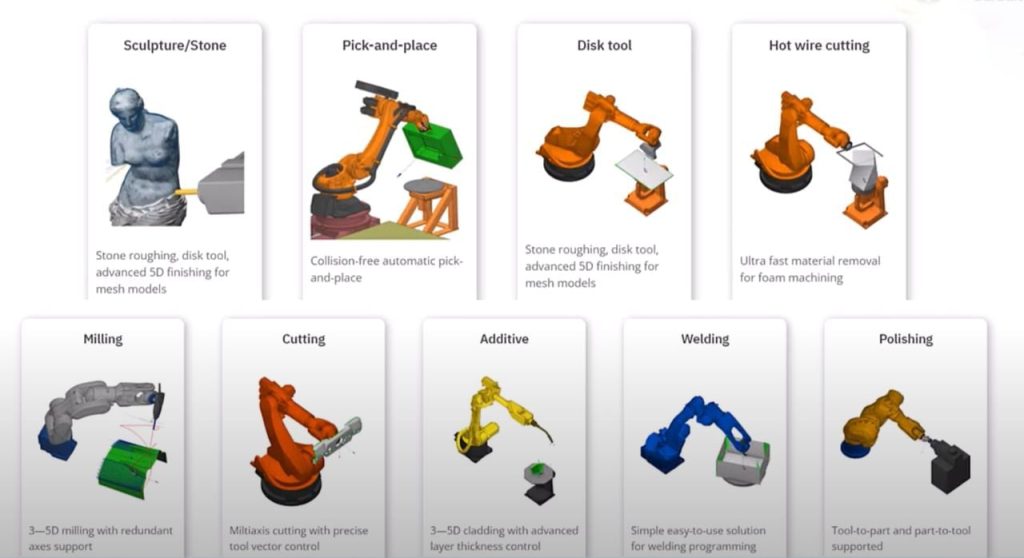

SprutCAM has produced software that can control these complex robotic motions with their SprutCAM X software. It’s used for a variety of industrial purposes, as you can see here:

Note that one of the many applications shown is additive. You can use SprutCAM’s software to control a robot that’s equipped with a 3D print toolhead (either metal or polymer) to actually perform a print job.

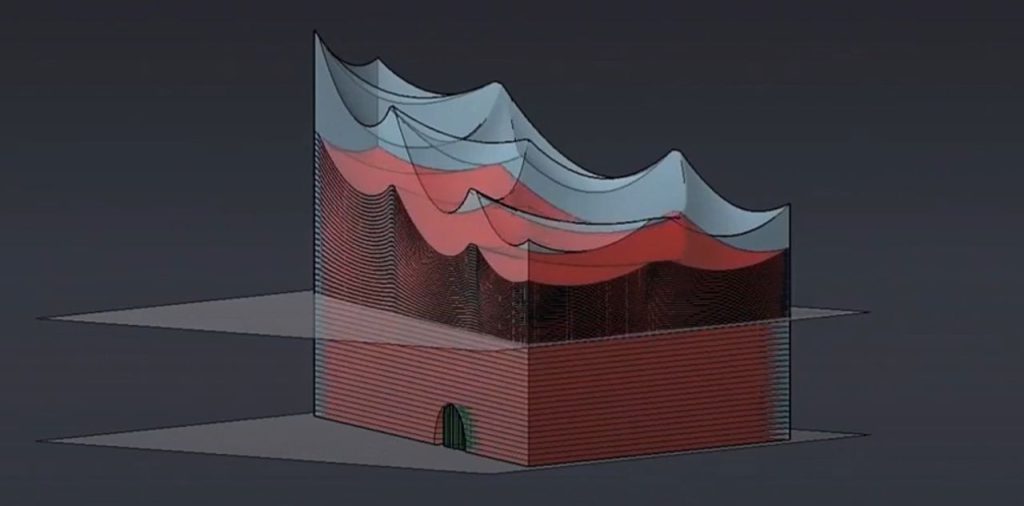

To do so, SprutCAM has developed “P3D”, a slicing extension to their software that can perform non-planar slicing. That is, slicing that is not in uniform layers.

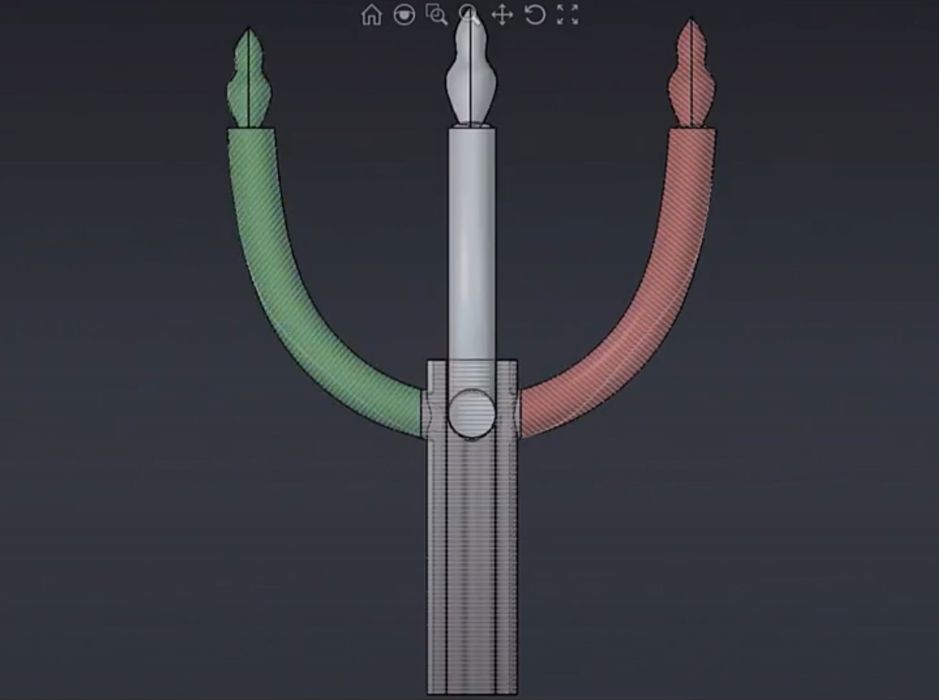

The software allows the operator to specify different slicing orientations within the print, as you can see here.

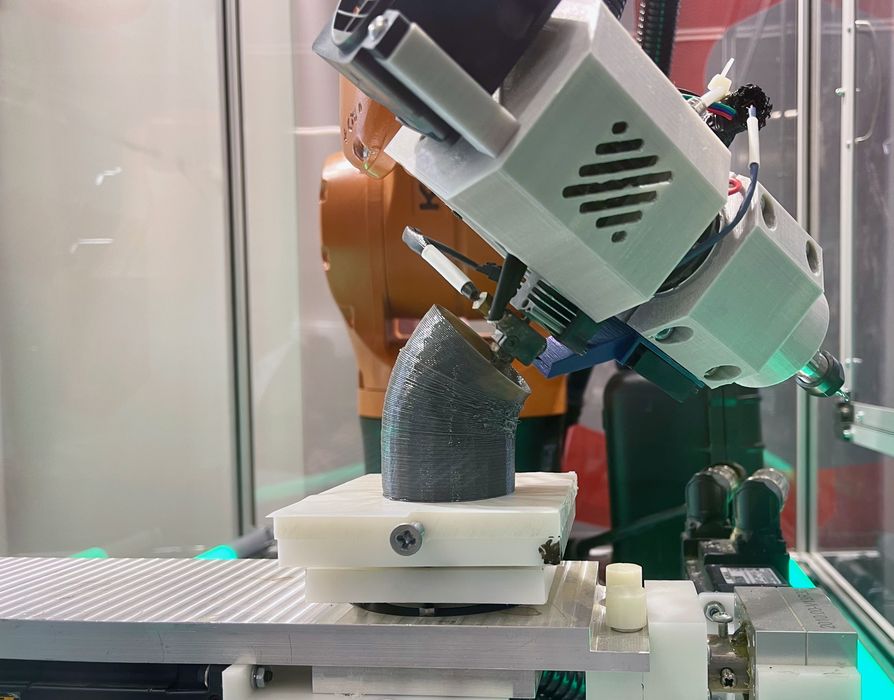

It can also slice in gradually changing planes, as you can see in the image at top.

This capability is not only fascinating, but provides a way for 3D printer operators to gain more strength in printed objects by aligning the extrusion directions along mechanical stress lines. It can also significantly reduce the amount of support material used.

However, using these techniques requires some training and a different way of thinking about slicing 3D models.

The presence of SprutCAM P3D and similar software has allowed many new entrants into the 3D print market. For example, if you use a standard robot, add an extrusion toolhead, enclose it in a heated box with a print plate, you have a robotic 3D printer — as long as you use P3D or similar software.

This is probably why there’s so many new robotic 3D printing options for industry recently.

However, experienced 3D printer operators will know that there’s a lot more to the job than just the motion system. There are considerable complexities in the handling of materials, thermal management, speeds and post processing, all of which must be done optimally, regardless of the machine configuration.

If you’re looking to develop an industrial robotic 3D printer, SprutCAM’s P3D could be a key element of the solution.

Via SprutCAM