Meltio has released a unique slicing system for its 3D printer.

The Spanish company produces DED-style metal 3D printing gear for industry, and in particular offers a hybrid solution for companies operating robotic solutions.

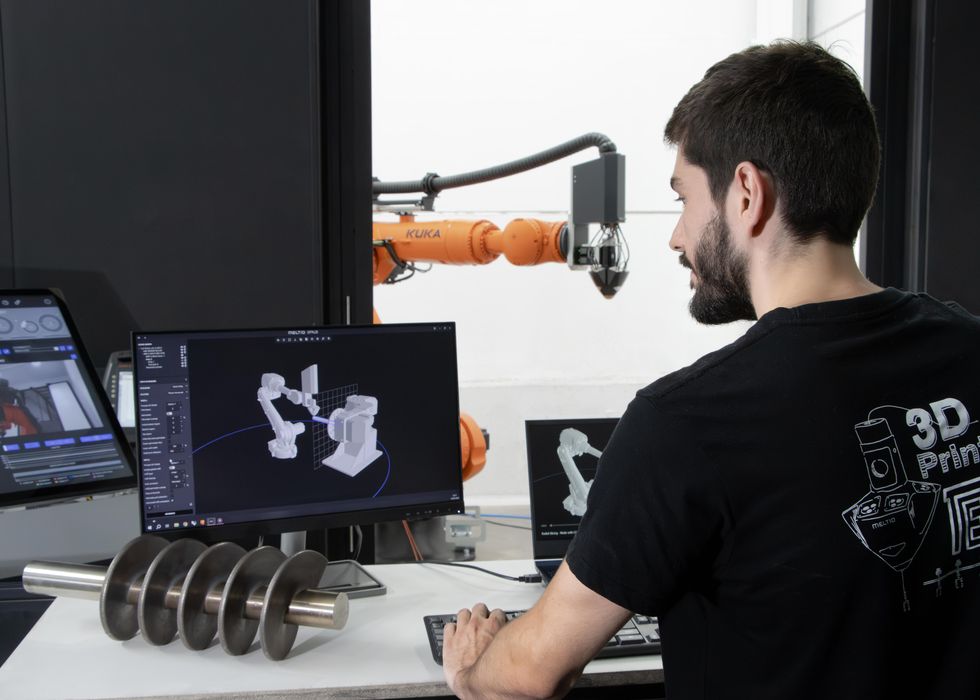

Their “Meltio Engine” is a way to convert an existing robotic system used for CNC milling into a fully capable metal 3D printer using their DED toolhead. This approach allows a far easier entry into additive manufacturing for companies as they simply modify an existing device to keep costs down.

To complete the system, Meltio has released a slicing software tool for the Meltio Engine, called “Meltio Space”. Meltio Space can generate toolpaths for companies operating the Meltio Engine system.

If “Space” seems like a strange name for a slicer, there is method in this madness, read on.

The first thing you must know is that the Meltio Engine is very different from typical 3D printers. Normally machines operate on a planar basis: one layer is printed on top of another. That’s not the case with the Meltio Engine because it is based on a robotic system, which can move in any direction at any time.

This provides a host of new opportunities for motion within a 3D print job, but also disqualifies other slicers that assume the world is planar.

Meltio Space allows operators near complete freedom of movement during a print job, and this can provide many advantages. One could be lowered use of support structures: overhangs don’t exist when you can reach under with the robotic arm. Meltio Space can handle six-axis robots from the most popular suppliers, including ABB, Kuka, FANUC and Yasakwa with their post processing capabilities.

Meltio has designed the software to be user friendly, and they say this:

“Prior to the launch of Meltio Space, the company had signed an agreement with 12 major software companies with which its technology is compatible and open. But, thanks to Meltio Space now the company facilitates the use or adoption of its wire-laser technology for industrial customers who do not have specific expertise in robotics and additive manufacturing, and all these capabilities are integrated in the new Meltio Space.”

It’s also friendly to those with robotic experience: The ability to easily use already-in-place robots will make operators somewhat more comfortable. Meltio believes the workflow should be simplified and allow the preparation of jobs in less time by operators.

Industrial robotic software is notoriously expensive, so I wondered how Meltio would handle this challenge.

The software is available by subscription, and Meltio is providing the first year for free with the purchase of a Meltio Engine. After that they say the price will be “very competitive”.

Via Meltio