Raise3D made a surprise announcement: they have a new 3D printer with a completely different printing process.

Raise3D has produced professional 3D printers for several years quite successfully. We performed a hands on test of their current flagship device, the Pro 3 Plus recently, and can attest to the device’s capabilities.

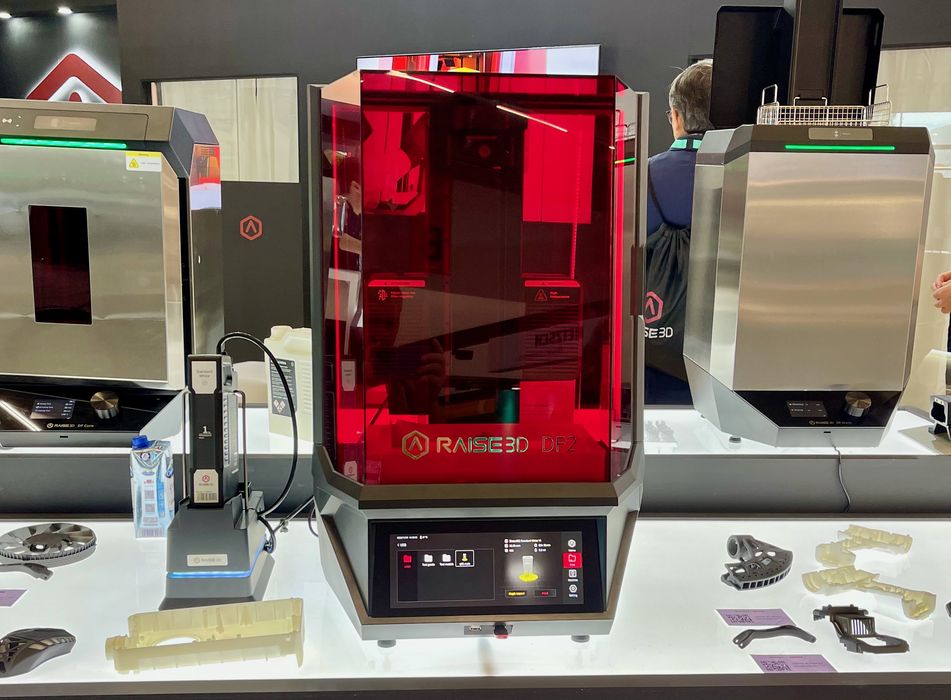

Now they’ve come out with the DF2, and it’s not a FFF device: it’s a resin machine. This is quite a switch for the company, which has never produced a resin device.

The market is quite crowded with desktop resin 3D printers, so entering that space requires some way to differentiate the product from others.

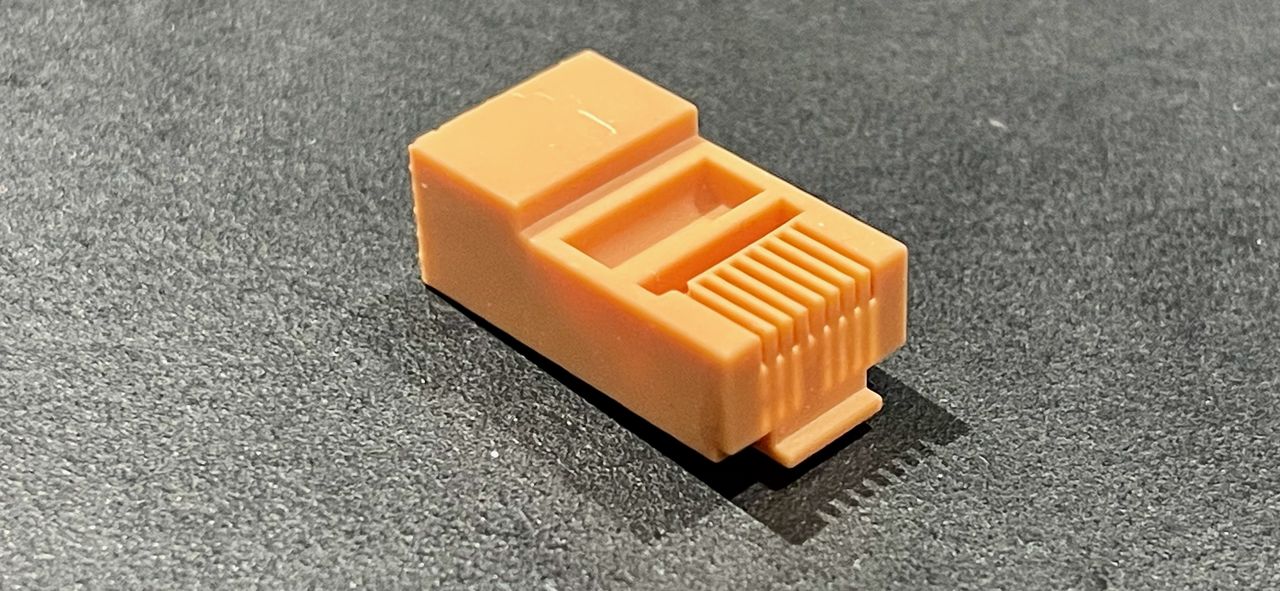

Raise3D has a strategy there: the DF2 environment will offer a combination of high quality results with a simplified end-to-end workflow. The DF2 system is designed for production, as the equipment, materials and workflow are set up to ensure consistency from job to job.

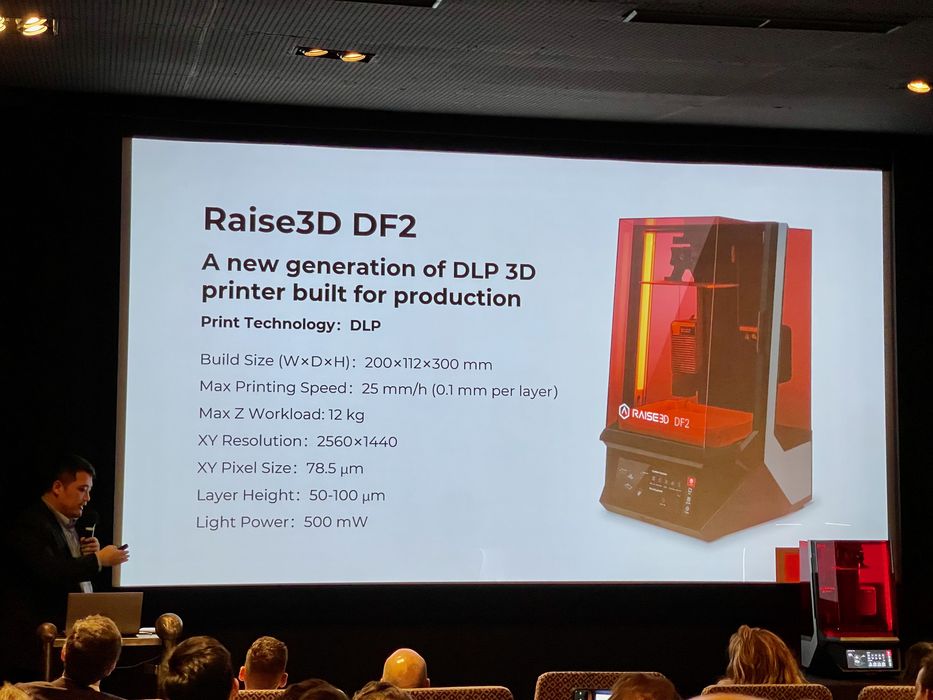

For quality, Raise3D has selected a DLP light engine for the DF2. Most desktop resin systems use an LCD approach, where light passes through an LCD screen. This is inexpensive and works reasonably well, except that the pixels are not actually square. They are “L-Shaped” due to the need for a bit of electronics for each cell of the LCD. That means that the optics must slightly blur the pixels to eliminate the “L hole”, and that can compromise print quality.

Meanwhile, the DF2 uses a DLP system, which involves a chip with microscopic mirrors. These produce fully square pixels and as a result the print quality can be much more precise. Raise3D has used “industrial grade” optics in the system as well.

The workflow is quite interesting as it is very different from others. Typically resin 3D printer operators take a completed build plate and toss it into a washer, and then a UV curing station.

The same steps take place in the DF2 concept, but it’s all under control. The print plate is RFID enabled, and when a job completes the system “knows” what material was printed and other job parameters. Then when the plate is put into the washer and curing stations, they know which recipe to follow for post processing automatically.

That means that you can actually do proper production with the DF2: parts will emerge with identical properties, job after job.

The system also includes an automated resin level detection feature, and if levels are low, it automatically “doses” the vat with more resin from the cartridge.

Raise3D has, as you might have guessed, made some changes to their IdeaMaker software to accommodate a resin system. The new features include:

- Antialiasing

- Auto-generated support structures

- Automatic orientation

- Automatic cross section analysis

- Contour compensation

- Suction cup detection

- Hollowing

- Drainage hole cuts

- Texture generation

- Compressed GCODE files

I should mention some of the basic specifications of the DF2. The build volume is quite generous at 200 x 112 x 300 mm, enabling printing of reasonably large parts. Raise3D said the system is capable of handling prints that weigh up to a massive 10kg through the robust nature of the Z-axis motion system.

The DLP resolution is 2560 x 1440 pixels, and by my calculations that means a voxel size of around 0.078mm, which is quite precise. Layer size is as low as 0.05mm, and the maximum print speed at 0.1mm layers is about 25mm per hour.

There’s also a massive 10.25 inch color touchscreen where you can control the DF2. Raise3D has implemented a feature to easily re-run print jobs, furthering the ease of production with the DF2.

Another unique feature of the DF2 is that the build chamber is heated, up to 40C. This is quite important for many resins that tend to be viscous. Heated resins flow much easier, making layer changes more reliable.

Raise3D has produced a selection of resins for use with the DF2, including a standard white material, a high detail material, a “tough” material and a “rigid” material. They plan on releasing clear and high temperature resins in the near future.

Note that these are resins from Raise3D that will follow the workflow system described above. It’s also possible to use third party resins in the DF2 through Raise3D’s Open Resin Program. The program will validate resins and provide print parameters.

The DF2 looks to be quite an interesting desktop resin 3D printer, particularly for low volume production of highly precise parts. It’s scheduled for shipping some time in 1Q24.

Via Raise3D