Ai Build has introduced something quite amazing: AiSync.

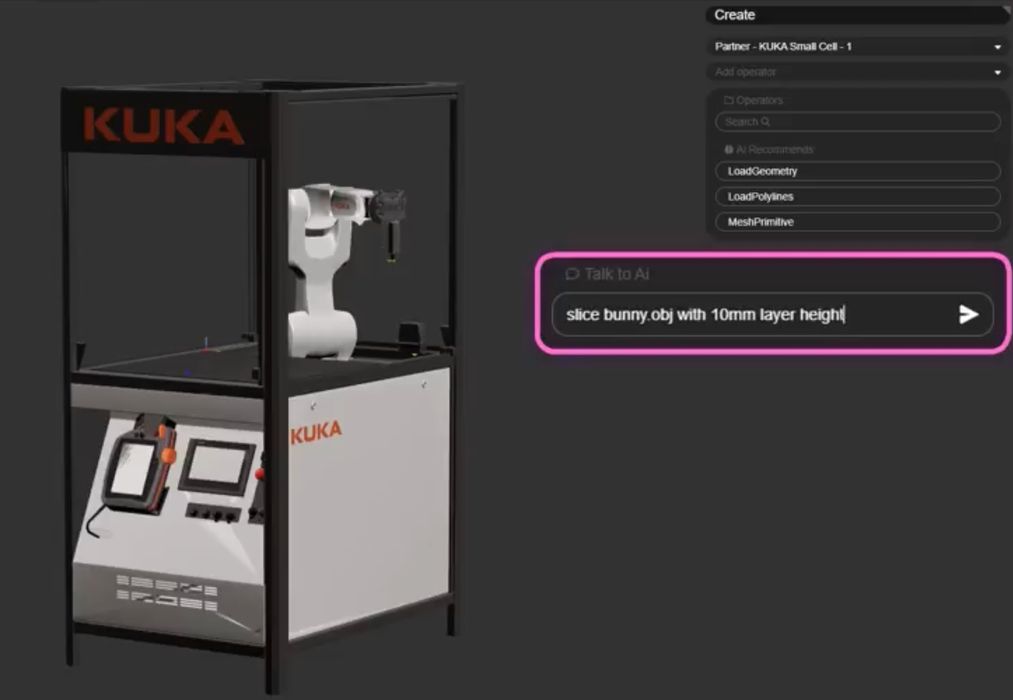

Ai Build is a London-based operation that is using various AI techniques to optimize additive manufacturing. Their technology involves a Kuka robotic system inside an “AiCell” to control the environment during printing, and the company has received a significant investment last summer.

The news this week is their announcement of “AiSync”, which is a highly advanced text interface to their job preparation software.

Setting up jobs in a professional setting can be a pain. While desktop 3D printer operators might not be too concerned about the strength of their plastic dragon, someone printing industrial parts that have very specific engineering property requirements may have other thoughts.

Achieving the necessary part strengths requires a careful configuration of slicing zones and other parameters to ensure the part comes out as intended. This usually means a lot of very tedious and error-prone tweaking in the slicer to get it just right.

That work may go away with AiSync, which is basically a text to slice interface. In a short video provided by Ai Build, you can see the operator enter text commands such as:

“Slice bunny.obj with 10mm layer height and infill”

And the system generates the correct slicing parameters to achieve this.

Then it gets more interesting:

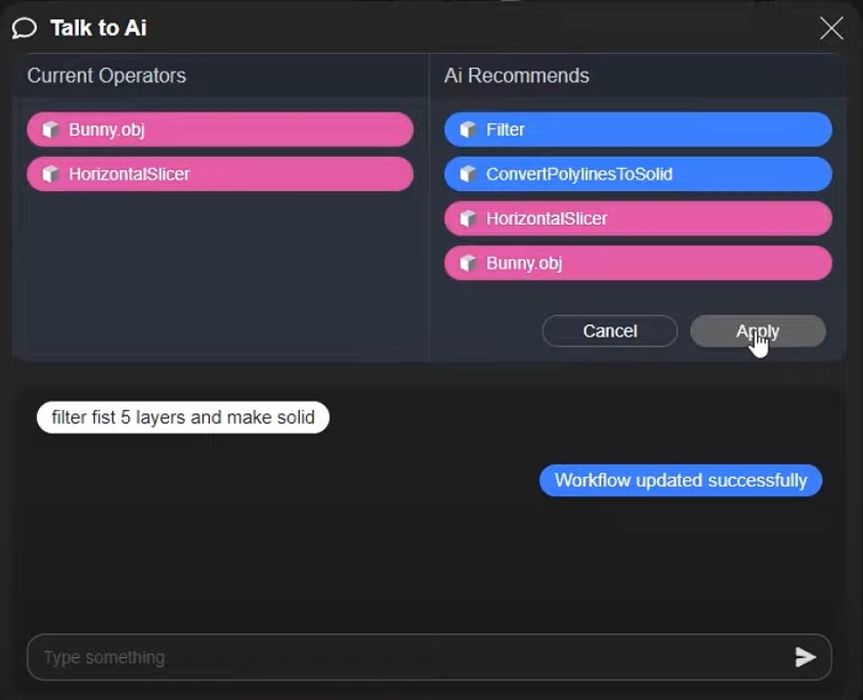

“Filter first 5 layers and make solid”

And the AI does just that. So, instead of setting up a new slicing zone and going through several parameters, AiSync seems to do this automatically, and instantly.

You can see how this works this video from Ai Build:

Here you can see a bit of the interface, as the AI is building up a series of recommendations for slicing.

It’s not clear how deep this tool goes, but one can imagine an enormous amount of tedious job setup could be automated in this fashion.

The idea here would be to vastly simplify the path to making use of currently challenging additive manufacturing processes. Today if you want to set up a proper industrial additive manufacturing operation you have to acquire not only equipment and materials, but also a staff with expertise in job setup and processing.

This approach could short circuit that need, which is often the most difficult to fill.

It seems that AiSync is designed for use with Ai Build’s systems, but the concept itself might also be attempted by others using slicing software for their own systems. We could see AI tools for the future interfaces for additive manufacturing become a normal approach.