Modix announced two interesting new add-ons for their large-format 3D printers.

The Israeli company produces a line of rather large FFF 3D printers under their “BIG” brand. The print volumes range from “only” 400 x 400 x 800 mm for their BIG-40, up to their enormous BIG-180X, which has a staggering build volume of 1800 x 600 x 600 mm.

Their equipment is built from top-grade components, including metal extrusions, linear rails, Duet 2 controller, and much more. The company has been quite successful in their large-format strategy, and now improves their design with a couple of changes.

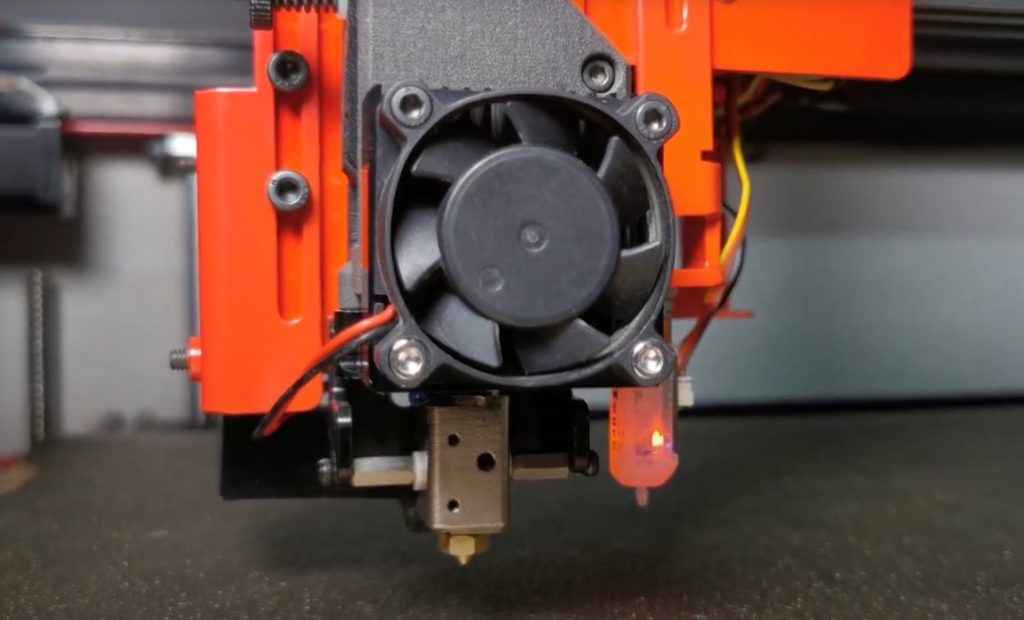

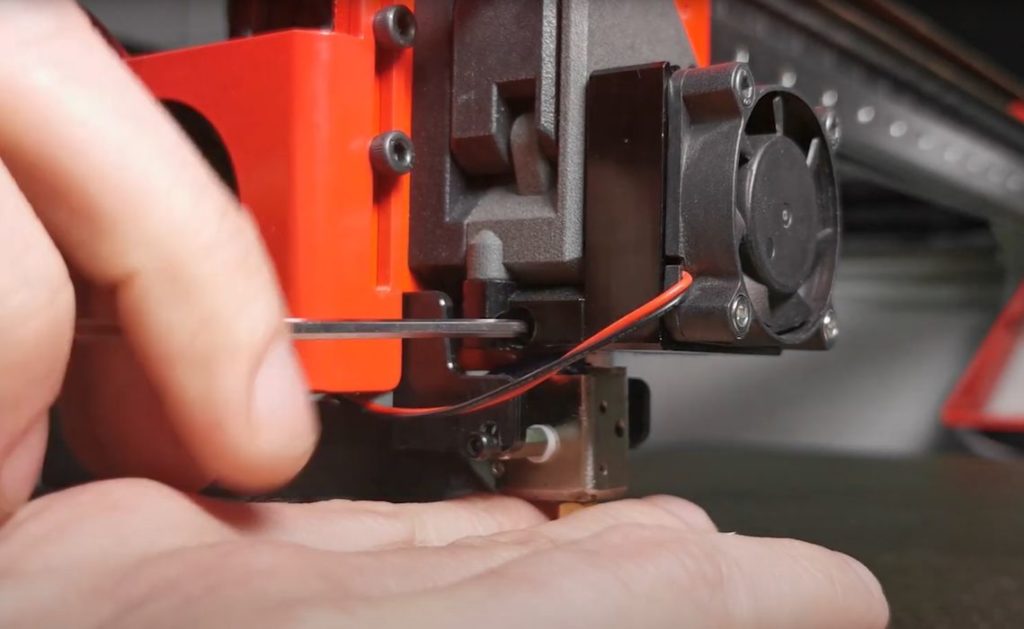

The first is a new hot end system they call “Griffin”. It’s a modular design that is easily swappable. In fact you can watch the entire swapping process in their video, which apparently takes only a couple of minutes and involves three screws and an Allen key.

The extruder is more reliable and potentially faster because it now uses dual Bondtech gears that grab the filament on two sides. The heat block is designed for efficient heat transfer, which again should enable faster 3D printing operations.

It’s also mounted in a very rigid frame that should protect it against damage should the nozzle hit a misbehaving print. In some other 3D printers it’s even possible to bend the hot end from such an impact. Aside: one of my previous 3D printers was designed in such a way that would permit the nozzle to strike the side of the print bed. I literally broke off three hot ends before I gave up. That kind of problem will not occur with the new Modix hot end.

The new hot end can now reach an amazing 500C, which might normally be a signal that the machine is able to 3D print higher temperature materials. However, in this case I think the high hot end temperature could instead be a way to increase the speed of printing.

Remember that as you speed up printing, every section of filament spends less time in the hot end as it passes through. If the speed is increased too much, then the filament doesn’t have time to absorb the heat and soften sufficiently. One way to enable faster printing is to increase the heat of the hot end so that a an appropriate amount of heat is absorbed by a fast-moving filament.

Modix representatives confirmed that it would be possible to run standard materials through a bit faster at hotter temperatures, but cautioned that you could not stray too far outside of the safe temperature range. This is because you’re not constantly printing at the higher speeds, as the job will have to intermittently deal with slower speeds in corners, etc. If the temperature is too high, then you run the risk of over-softening or burning the filament, neither of which are good things.

It appears that this new extruder could be the first step Modix has taken towards a true, high temperature 3D printer that could handle materials like ULTEM or PEEK. However, that would require a pretty fancy enclosure, as the company’s equipment tends to be rather large. We’ll keep watch for their moves in that direction.

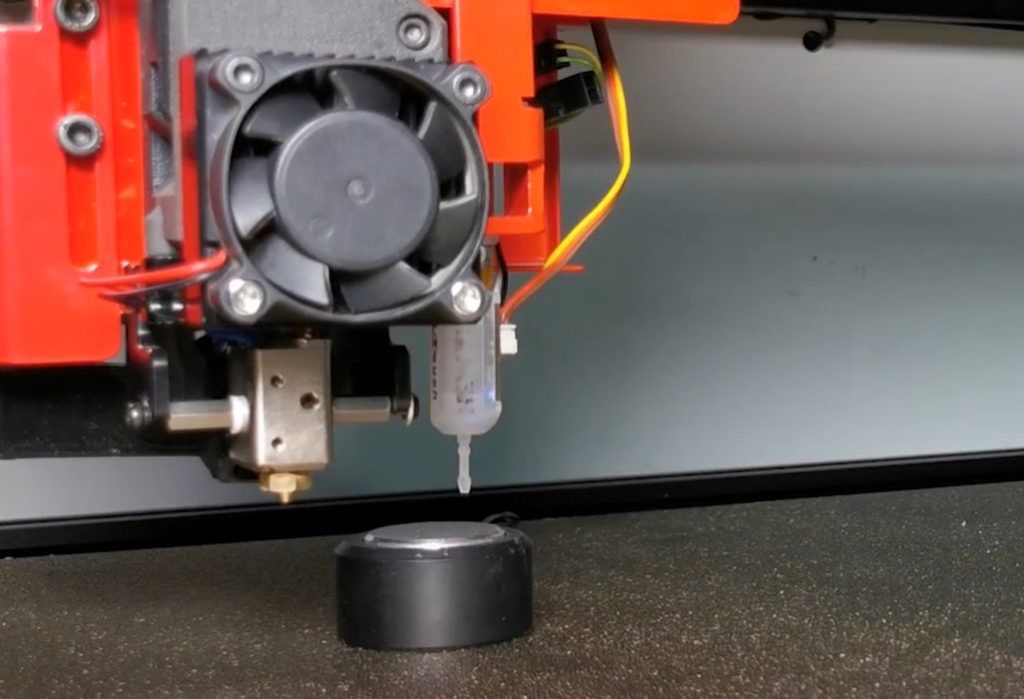

The second add-on Modix has revealed is a unique system for precisely setting the z-gap.

The z-gap is the distance the nozzle must maintain above the print bed for the critical first layer. If this is not set optimally, then there is a risk of print detaching during the job because it wasn’t firmly attached on the first layer.

The new Modix system involves placing a special “puck” shaped device on the print bed. This is then probed by the hot end and BLtouch sensor to precisely set the z-gap to a 0.001mm accuracy. This should ensure prints are properly attached to the print surface for all jobs, and increase print reliability.

Two very interesting and highly useful additions to Modix’s 3D printing equipment.

Via Modix