Charles R. Goulding and Preeti Sulibhavi discuss the history of the Jacuzzi family and how 3D printing can be used for different aspects of hot tubs.

“Aqua Vita Est.”

Water is life. This is the unofficial motto of the Jacuzzi family. You may relate the famous name to fancy hot tubs, but the monicker, Jacuzzi, refers to much more than that.

A traditional, hard-working, Italian family makes its way to the US and builds a better life. Sounds like your boiler-plate immigrant success story. Maybe. But this one refers specifically to the Jacuzzi family.

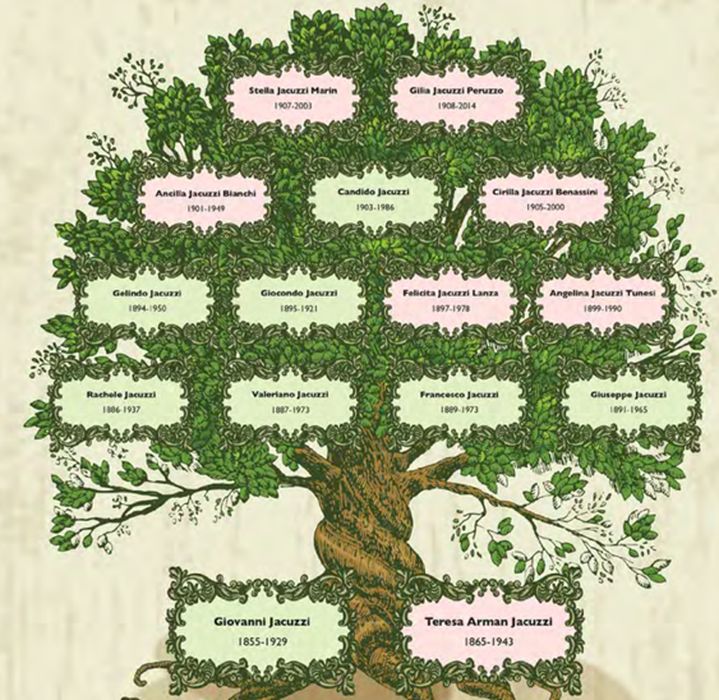

Originating from a rural farming community in Northern Italy, the Jacuzzi clan comprised of Giovanni and Teresa and their seven sons and six daughters fled one by one during World War I.

They had humble beginnings and worked on everything from airplanes to farming and irrigation equipment.

After their aviation business took a deep dive, the Jacuzzis rode the hot tub wave. It all began when Ken, Candido Jacuzzi’s son, developed a degenerative disease and lost mobility at the age of just 15 months. The Jacuzzis saw that hydrotherapy worked wonders for their ailing son. The rest is history.

In an August 13, 2023, New York Times SundayStyles piece, which featured both the Jacuzzi family history as well as the evolution of its famous hot tubs. The acquisition of the Jacuzzi brand by American Industrial Brands in 2021 was not an easy one for the family. But when one door closes, another opens. We see this as an opportunity to integrate more 3D printing into the hot tub industry.

Hot Tubs, Plumbing and 3D Printing

Plumbing and 3D printing are commensurate industries. One can support the other and both can be integrated to produce high quality, cost-effective products (as we have previously covered). Kohler has utilized 3D printing in its innovation efforts. And, with the passage of the CHIPS Bill in 2022, many successful plumbing companies pivoted from residential work to providing much-needed HVAC and plumbing to the burgeoning semiconductor market.

Hot tubs are not excluded from this trend. The components of a hot tub include its shell, cabinet, pumps, hydro jets, blowers, controller and heater (spa pack), controls, lighting and filters (sanitation). Many of these components are amenable to being 3D printed. In fact, the acquisition of Jacuzzi by American Industrial Brands can help Jacuzzi innovate further by integrating 3D printing into its designs.

Many hot tubs come with accessories. Some may include a towel rack, handrail (for easy entry and exit), food or beverage trays and the list goes on.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The Jacuzzi family history is inspirational. A hard-working family turns their efforts to improve their son’s health into a global brand that denotes quality and luxury. While the Jacuzzi trend may not be as popular as it was in the 1970s or 1980s, with the advent of COVID-19, many families have been involved in home improvement hobby projects – hot tubs are one item to add to their lists. The 3D printing industry can find opportunities to advance this trend.