Intech Additive Solutions announced a new metal 3D printers that has a much bigger build volume.

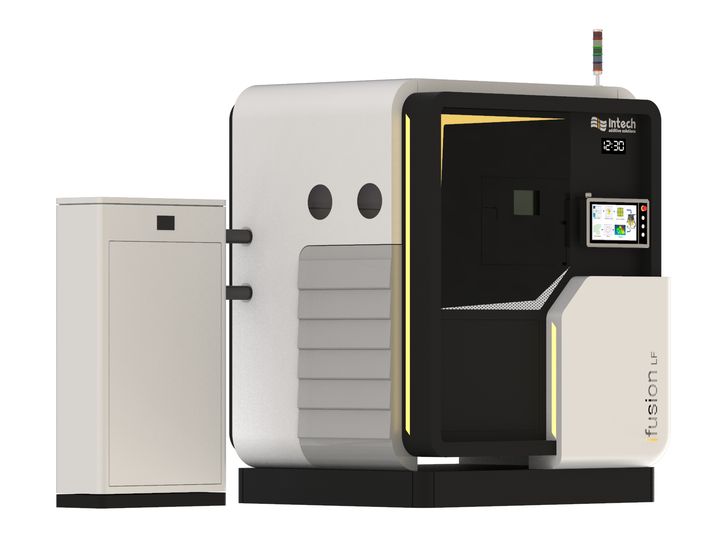

The Bengaluru-based company has existed since 2012, but more recently produced a metal 3D printer, the iFusion SF1. Building on the success of that machine, they have now announced a new metal 3D printer, the iFusion LF. “LF” stands for “Large Format”.

The iFusion LF uses the LPBF process, and offers a build volume of 450 x 450 x 450 mm, able to produce quite large metal parts. The machines come with a standard 500W laser, but there are upgrades available to either 700W or even 1000W to allow for more rapid 3D printing.

Intech said the LF series is compatible with a variety of metal powders, including aluminium, cobalt chrome, stainless steel, maraging steel, titanium and Inconel.

Intech has provided “established parameters” for the above materials, making it relatively straightforward to obtain good print results immediately.

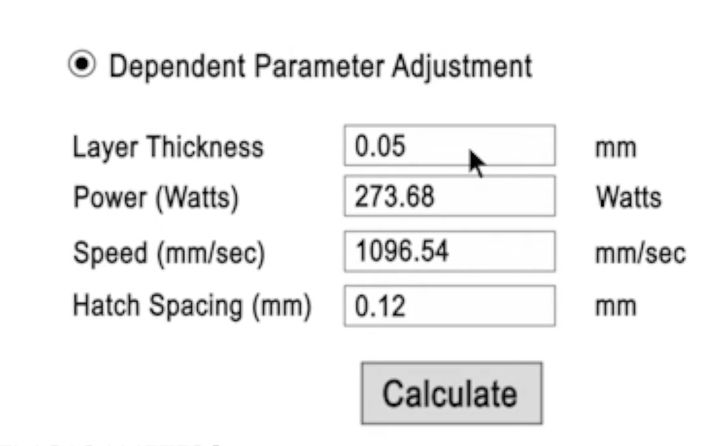

One of the unique features of the iFusion series is that Intech provides their own suite of sophisticated management software. There’s a tool to prepare print jobs, AMBuilder, but there’s also an interesting additional tool called AMOptoMet.

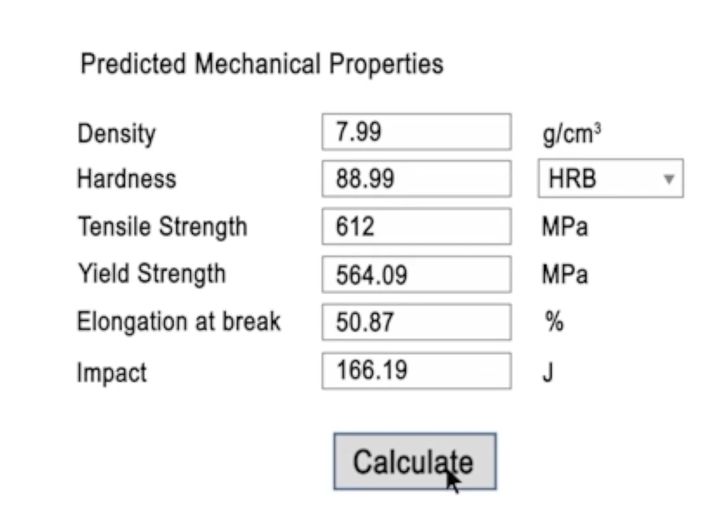

AMOptoMet is a tool that can automatically generate optimized print parameters, with a goal of achieving the best surface finish on the prints. It’s quite interesting as you can specify a mix of materials and the software automatically calculates the predicted strengths of the resulting 3D print.

It can also generate 3D print parameters. You specify the independent parameters, and it calculates the parameters dependent on them. This software looks extremely useful.

Intech is targeting the machine at several key industry sectors, including automotive and aerospace. Apparently they’ve already signed deals for the equipment with an Indian UAV manufacturer.

There’s another aspect of Intech’s business that warrants discussion: their locale. They design, build and sell their equipment in India, and as such they are one of the few who do so for this type of metal 3D printing equipment. The only alternatives would be to purchase equipment from distant manufacturers, and this would require lengthy and expensive shipping, insurance and customs duties.

To complement the “made in India” approach, Intech also provides a full set of local service with their engineering team, making a purchase much more comfortable for local industry.

This is good news for Indian buyers, but perhaps less good news for non-Indian 3D printer manufacturers hoping to sell equipment in that country. It would be difficult for foreign firms to compete against a local company with connections, integration with the economy and culture, etc.

I’m wondering if we could see similar ventures in other countries that wish to localize their 3D printing ecosystems. If India can do this, other countries could do the same. This may suggest today’s larger 3D printer manufacturers had better beef up their regional operations.

Via Intech and Hindu Business Line