SPONSORED CONTENT

INTAMSYS was one of many who attended the recent TCT Asia trade show.

TCT Asia was one of the first large-scale in-person 3D printing events to take place since the beginning of the pandemic in 2020, and the 2021 event was attended by over 11,000 attendees and 250 exhibitors. This makes the event one of the largest in the world after Formnext and RAPID + TCT.

I can’t say enough about the benefits of attending an in-person 3D print event. You can see and touch 3D print samples, ask questions, peer inside machines and generally learn far more than you can from websites or even webinars.

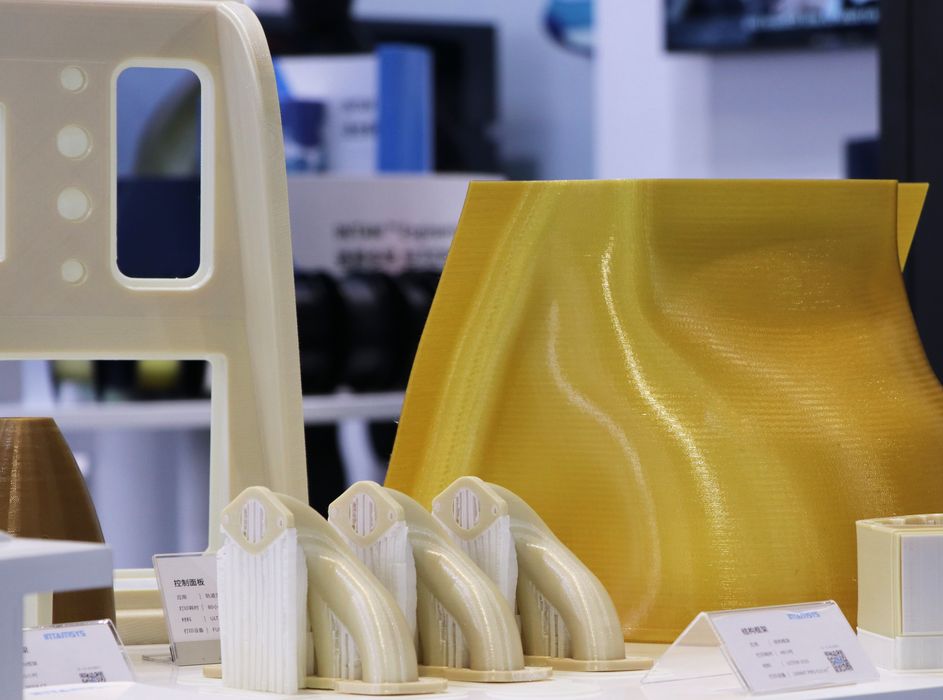

That capability was leveraged to the fullest by INTAMSYS, a maker of high-temperature 3D printing gear for industry. Their popular INTAMSYS FUNMAT PRO 610 HT was featured at the show. The system is equipped with a 500C nozzle and build chamber that can maintain 300C for long duration print jobs, and this enables it to print parts in exotic engineering materials such as PEEK, PEKK or ULTEM.

Not only that, the machine has a massive build volume of 610 x 508 x 508 mm, making it possible to produce large parts. This is quite impressive because the exotic materials mentioned above are normally challenging to 3D print without warping. The FUNMAT PRO 610 HT’s 300C build chamber temperature easily takes care of that issue.

INTAMSYS bills the FUNMAT PRO series of 3D printers as open material devices, meaning an operator is free to use any reasonable material in them without technical restrictions. This allows operators the ability to test and use exotic materials that might not be feasible available for other equipment.

That said, the company also introduced a new line of 3D printing filament brand specifically designed for use in their equipment.

INTAM Filaments

The new brand is called INTAM filaments and it organizes their filament offerings in a sensible manner. There are, at launch, four categories of materials in the INTAM line:

INTAM Performance

These materials are the filament options that provide both mechanical performance and very high heat resistance. Included are:

- PEEK

- PEEK-CF (Carbon Fiber)

- PEEK-GF (Glass Fiber)

- PEKK

- ULTEM 9085

- ULTEM 1010

- PPSU

- PPS

INTAM Engineering

These materials function in lower temperature ranges, but offer a wide range of engineering capabilities. They include:

- PC

- PC-ABS

- PC-PBT

- PC-FR (Flame Resistant)

- PA

- PA6-CF (Carbon Fiber)

- PA12-CF (Carbon Fiber)

- ABS

- ASA

- PLA

INTAM Elastic

At the time of this writing, INTAMSYS offers only one option in the INTAM Elastic category, TPU 95A. It’s likely they will add more as time passes that might have different shore values.

INTAM Support

INTAMSYS offers five different support materials that cover the range of the other INTAM materials. Note that you need special support materials to withstand the extreme temperatures when printing their High Performance materials. They include:

- SP5000 (For most high-temperature materials)

- SP5030 (Breakaway support for ULTEM 9085)

- SP3040 (Water soluble, higher solution rate)

- HIPS (Breakaway support for lower-temperature materials)

- PVA (Water soluble for lower-temperature materials)

INTAMSYS also cooperates with Victrex and promotes their Victrex AM 200 filament, which is a PAEK material with a high Z-direction strength.

By organizing their materials under the INTAM brand, INTAMSYS clients will be assured that these materials have been certified for use on the equipment, and can make use of pre-made print profiles for quality print results. The INTAM brand already contains quite a number of exotic materials that are 3D printable on the company’s high-temperature equipment, but it’s likely INTAMSYS will add more in the future.

Via INTAMSYS