There’s been another development in the science of recycling polymers that could affect 3D printing.

Researchers at RWTH Aachen University have been investigating the problem of breaking down specific plastics. This is inspired by the ongoing microplastics crisis.

Our habit of using and discarding plastic items is beginning to catch up to us. These discarded items, whether in landfills or the ocean, mechanically break down into tiny particles, sometimes even dust-sized.

These microplastics then blow or flow around the world, and now they are basically in every environment, even the distant arctic. Their presence then gets into the biosphere and ultimately into our own bodies.

That’s right, a small percentage of your body is actually made of microplastics, right now. And worse, we don’t really know what those chemicals are doing to you in the long term.

Because of this, I expect that there will be a gradual shift towards recyclable 3D print materials. In fact, it’s already happening. Materials companies I speak with have already have begun to receive requests from large buyers that require sustainability information or constraints.

However, most 3D printing is still performed with difficult—to-recycle and non-biodegradable materials such as PLA, ABS, ASA, PETG and others.

Is there any hope of dealing with these materials?

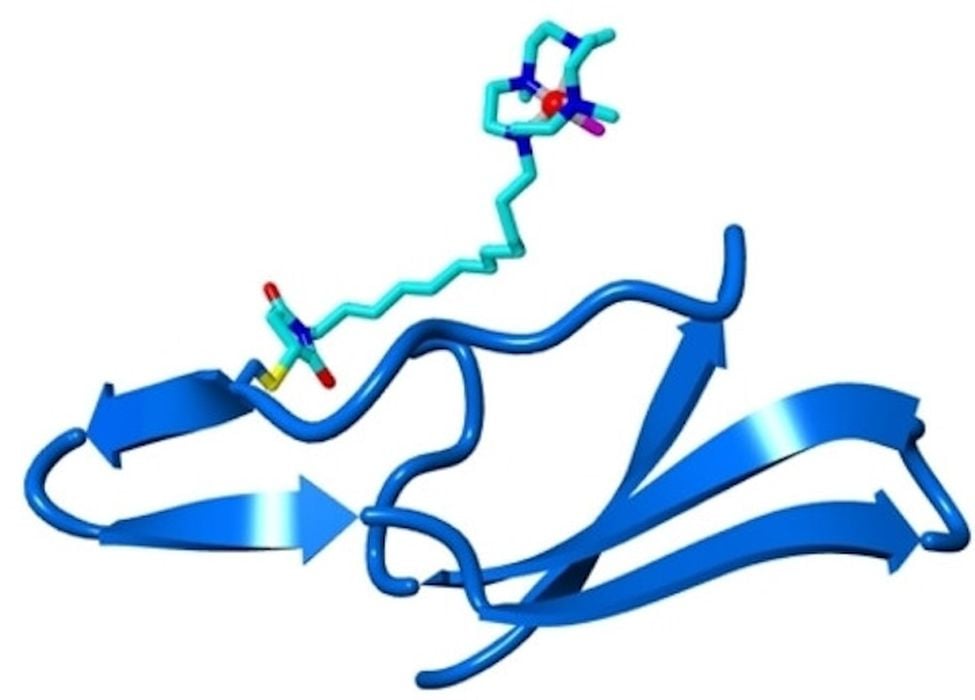

It turns out the new research may point in a direction that could help with this issue. They’ve identified chemistry that breaks down styrene molecules in a paper entitled, “Engineered Anchor Peptide LCI with a Cobalt Cofactor Enhances Oxidation Efficiency of Polystyrene Microparticles”.

The gist of what they have discovered is that a specific peptide, when combined with oxone, can break down styrene microparticles.

Styrene is a very common microplastic pollutant, and get this: ABS stands for Acrylonitrile Butadiene Styrene”. It’s a styrene, and therefore can be broken down with this new peptide.

That’s very good news, as it seems that the process is quite effective and efficient. This might mean it may in the future be adopted by recycling centers that would be able to decompose ABS materials.

But what about the other commonly used polymers? The researchers write:

“It is very likely that the general concept of polymer degrading biohybrid catalysts can be expanded to hydrophobic polymers such as PP or even PE owning to LCI’s binding properties. Through coating at ambient temperature, the biohybrid catalysts for polymer degradation reported here could be scalable and energy-efficient.”

This would potentially enable sort-free plastics recycling systems, and help with the growing mountain of 3D printed plastic waste.

Via Wiley