Researchers at the University of Tokyo have developed a way to 2D print 3D objects.

That’s something that might not make sense at first, but it turns out that’s precisely what they are doing. The method is called “Inkjet 4D Print”, and it leverages 4D concepts using 2D printing.

4D printing is the science of printing a 3D object and then having that object change its geometry after production. That is done by leveraging some property of the materials used, such as differing rates of thermal expansion.

4D printing would typically involve printing an object that’s much larger than the build volume of the 3D printer, and then having it “unfold” afterwards into the final shape.

That’s the 4D concept, but what’s happening in the new research? They write:

“We propose Inkjet 4D Print, a self-folding fabrication method of 3D origami tessellations by printing 2D patterns on both sides of a heat-shrinkable base sheet, using a commercialized inkjet ultraviolet (UV) printer.”

It’s therefore NOT 3D printing, as they use a 2D UV printer. However, the process does produce 3D objects.

The researchers propose a number of advantages of Inkjet 4D print over earlier 4D methods that use 3D printers, including:

Higher Resolution: The UV printer can reach 1200 times higher resolution, equivalent to what you’d see on a page of a magazine. That’s far higher resolution than the typical 0.1mm extrusions from an FFF device.

More Complexity: The added resolution enables the creation of far more dense self-foldable facets in the design, making more possible geometries.

Faster Production: The UV printer is a high speed device that can produce output at a much faster rate than FFF 3D printers.

Full Color: The UV printer is designed to print in color, and thus the printed 4D objects can have color textures if required.

The process is both hardware and software. The idea is to design a mostly 2D structure that includes layers of differing thermal expansion properties. By controlling the strength of regions within each layer, it’s possible to generate folding by the application of some heat.

The problem then is to devise software that can leverage this phenomenon to produce desirable geometries. That seems to have been solved by the researchers, who were able to produce 3D objects using the technique.

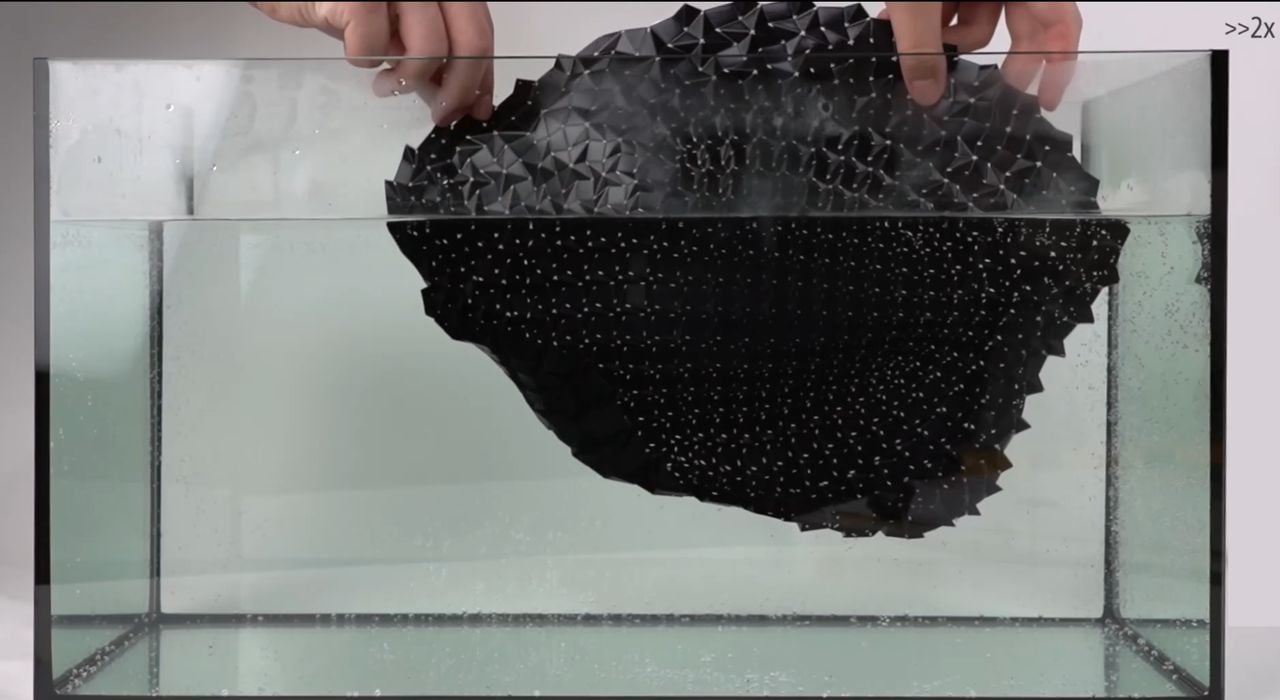

At top you can see a hat produced by the process. The site below includes a video showing the process, where a floppy flat black item is produce on the printer. It’s then immersed in warm water, where it near instantly folds into the hat shape. Dry it off and you have a baseball cap ready to wear.

While there will certainly be some constraints on the possible geometries that can be made with this approach, there will also be many items that can be made in this way.

Since the process seems to be well-adapted for large scale production use, it would seem clear that it could be used to produce many flat items for sale that can be “4D’d” later by the purchaser.

Imagine heading into a store and buying items that are simply flat planes that transform themselves into the actual product later.

Also imagine the effect on shipping: what if items were all flat instead of 3D? This method could very dramatically affect shipping efficiency.

On the other hand, imagine a shipping container of 2D hats when the air conditioning fails. Exploding hats! Progress is never easy.

Nevertheless, this is a very interesting approach that might even make its way into a desktop form for hobbyists.

Via Narumi