Inkbit, it seems, has firmly etched its name in its very own 3D print application niche.

My recent tête-à-tête with Inkbit representatives at the RAPID+TCT event in Chicago was quite enlightening, shedding light on the company’s forward march strategy. If you’re still playing catch up with their unique 3D printing process, let me break it down for you.

Vision Controlled Jetting: The Game Changer

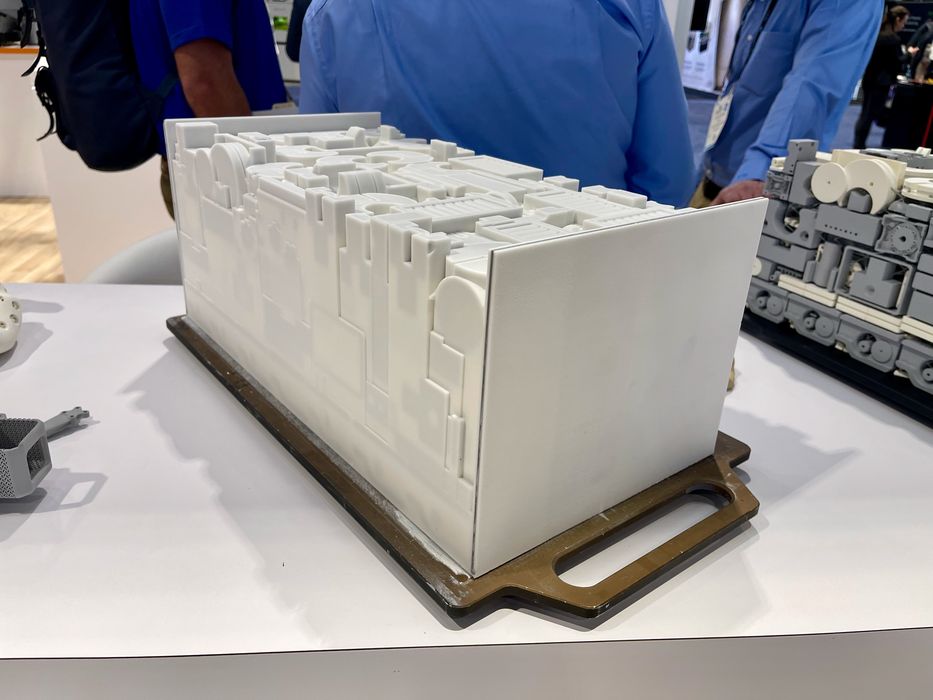

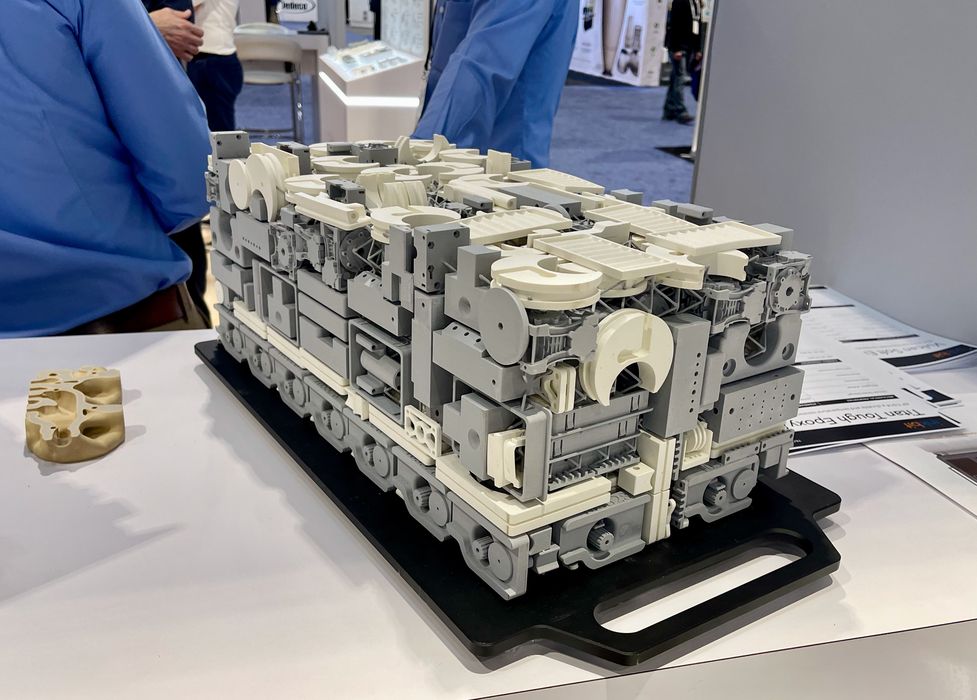

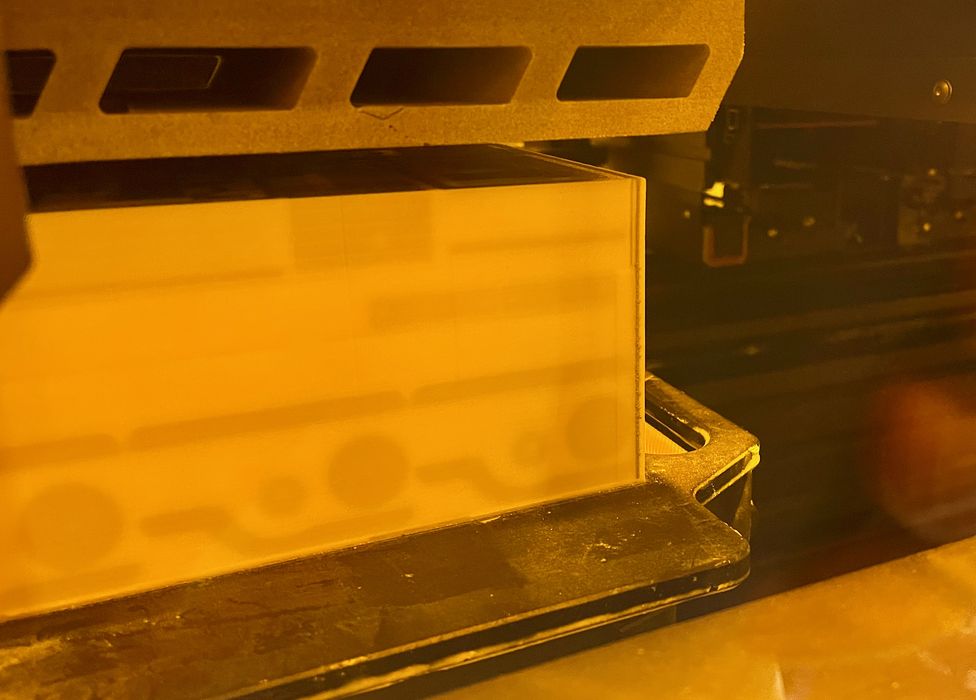

Their process, referred to as “Vision Controlled Jetting” or VCJ, is nothing short of revolutionary. It leverages high-density inkjets to selectively layer up to four different materials. Think of VCJ as sculpting a solid block of these materials within a 500 x 250 x 250 mm space. And here’s the kicker, they use wax as a support material.

Once the print job is done, what you have is a mammoth block of wax with all your printed objects encased within. Melt away the wax, and voila! You have your finely detailed prints inside, ready for use.

The genius of the wax approach is that it facilitates incredibly intricate geometries for printed objects. Imagine a contorted tube with a 1mm inner diameter—printing such a structure with any other 3D printing process is something I’d call a tall order.

The Drone Sector: A Promising Application for VCJ

Inkbit has poured substantial resources into refining the printing process, aiming for print reliability and consistency. As the “block” zips back and forth inside the printer, it’s crucial to maintain unerring positioning and velocity. That’s a puzzle Inkbit seems to have cracked, paving the way for large-scale production of dimensionally accurate parts apt for end-use applications.

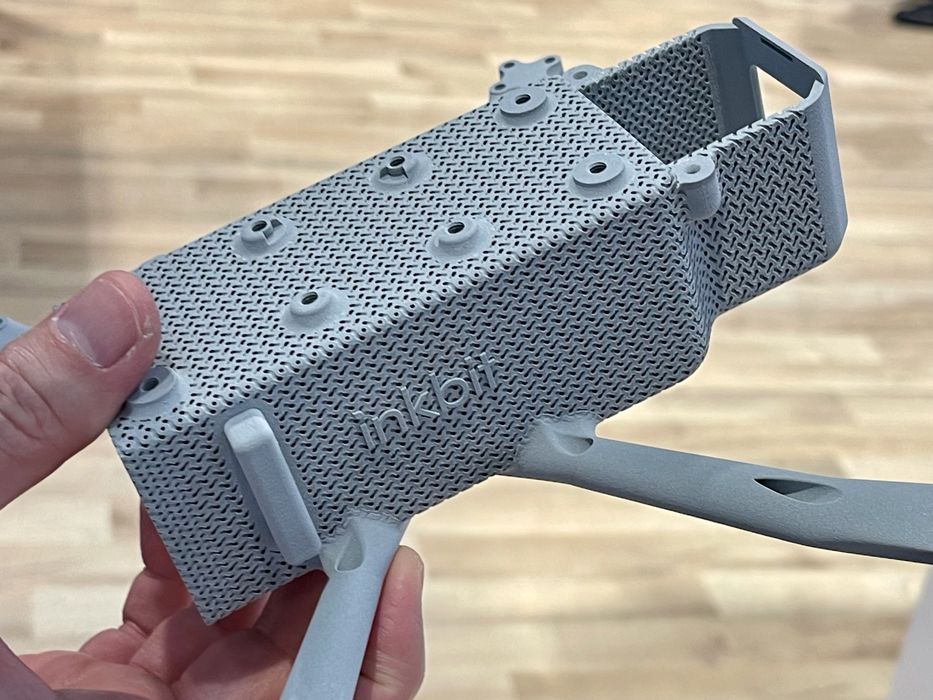

Recently, Inkbit has set its sights on specific applications that can exploit VCJ’s capabilities. Drones, for instance. With VCJ, Inkbit can churn out highly accurate parts in volume, perfectly tailored for drone use.

Take a gander at this prototype drone housing, for example. It’s been strategically lightweighted using a lattice design. What’s more, this is a single part that includes components that would usually be built from multiple parts. The need for screws to bind these parts? Gone.

Inkbit’s CEO, Davide Marini, envisions a manufacturing future sans the “assembly journey”, creating parts in this style. The ultimate aim? Print the entire mechanism. This is a power punch that could significantly alter how manufacturers design their products and the frequency of those changes.

An intriguing possibility that Inkbit might explore in the future is a “pick and place” capability in their equipment. This would allow the production of not just the plastic part, but also the embedding of other non-printable components, such as wiring or electronics.

While that might be the future, for now, Inkbit has built a robust manufacturing system capable of producing high-resolution parts with remarkable throughput.

Via Inkbit