The Builder Extreme 1500 Pro is an impressive industrial 3D printer.

Builder, based in Netherlands but also with an office in the USA, has been developing large-scale extrusion-based 3D printers for many years. These days they have quite a lineup of large-scale 3D printers on their product shelf, ranging from the Extreme 1000 Pro with its 700 x 700 x 820 mm build volume to the large Extreme 3000 Pro, which has a massive build volume of 1100 x 1100 x 820 mm.

In the middle of their line lies the Extreme 1500 Pro, which has an intermediate build volume of 1100 x 500 x 820 mm, large enough to handle all but the most extreme parts.

The extrusion system is a dual-feed arrangement that’s been developed in-house by Builder itself. Using 1.75mm filament, the machine is certified to print PLA, PET, PVA, certain composites, flexible materials and their own ABS-style PRO1 material. I’m pretty sure there are plenty of other materials usable on this device, including PC, ASA and ABS.

Since the 3D prints made on this device are quite large, Builder has made the ability to swap nozzle diameters easier with the addition of optimized print profiles for 0.4, 0.8 and 1.2mm nozzles. The larger nozzles can dramatically shorten print job durations as they deposit more material each second.

Printing large objects in some materials can be challenging, as materials can thermally distort during printing, commonly known as “warping”. This is notably evident on large prints, where forces are amplified over the longer dimensions of the print.

To counteract this, Builder has a secret weapon: a heated chamber.

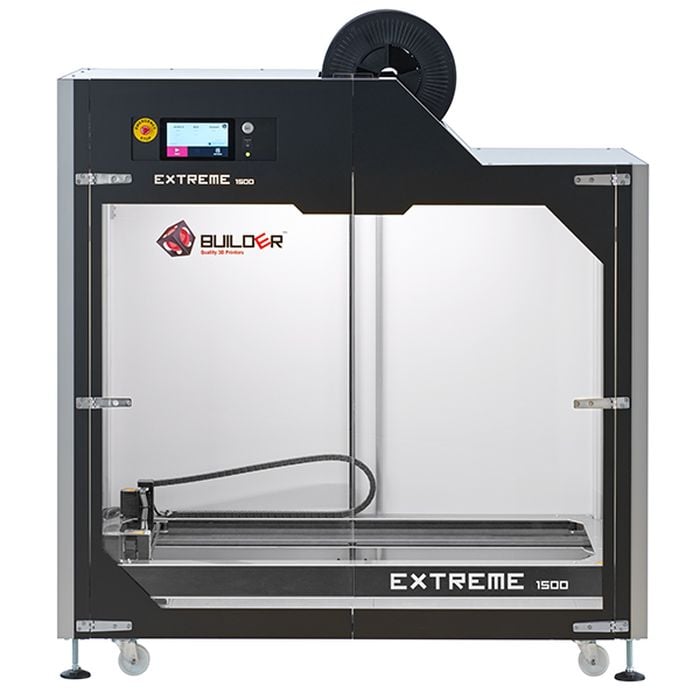

Notice that the standard Extreme 1500 Pro appears like this:

While the image at the top seems quite different. However, if you look closely you’ll see that the Builder Extreme 1500 Pro is built into a frame that provides the heated chamber: the entire machine is heated.

In this advanced version, the extruder is water-cooled to counteract its surrounding hot environment, which can be as high as 70C. There’s also an air filter that not only cleans the air, but recycles hot air back to the machine, saving considerable energy.

The thermal management systems on the Extreme 1500 Pro enable the use of many engineering materials in a practical sense: they are far less prone to warping due to a reduction in the thermal gradient.

Although there are many other large-format 3D printers and 3D printers with heated chambers, there are very few that combine both: a large-format, heated chamber 3D printer.

Builder said the standard Extreme 1500 Pro goes for US$35,000, while the heated chamber version is priced at €50,000 (US$54,000).

If you’re looking for a way to reliably 3D print large objects in a variety of engineering materials, Builder seems to have several good options.

Via Builder