SPONSORED CONTENT

The pace at which AM technologies has accelerated to improve performance, lower lifecycle costs, and help domestic industrial production are contributing to an increased use of AM. One of the most efficient way to increase productivity per employee and create a lean supply chain is by implementing digital technologies such as additive manufacturing.

The people and companies propelling AM forward will connect at IMTS 2022 – The International Manufacturing Technology Show, which has become a primary AM destination.

IMTS is the well-known manufacturing trade show that’s so huge, it takes place only every second year. From Sept. 12-17 at Chicago’s McCormick Center, IMTS 2022 will be filled with equipment, demonstrations, conference sessions, and people related to all manner of manufacturing gear.

The event in total is expected to showcase more than 2,000 exhibitors of manufacturing solutions covering 1.2 million square feet, host tens of thousands of visitors, and provide a considerable amount of additive manufacturing content. The additive solutions are sufficiently numerous that IMTS has placed them in a dedicated location, the AM Pavilion, one of nine different pavilions at the event. Additionally, AM can be found throughout the other pavilions including hybrid systems in the Metal Removal Pavilion, metrology solutions in the Quality Assurance Pavilion, and software in the Controls & CAD-CAM Pavilion.

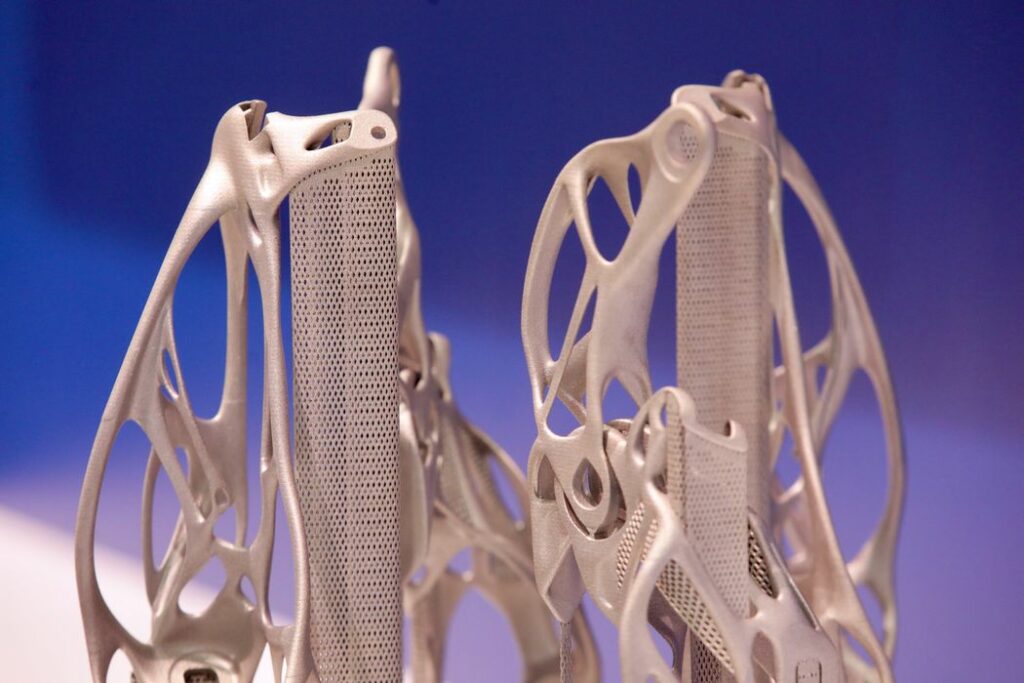

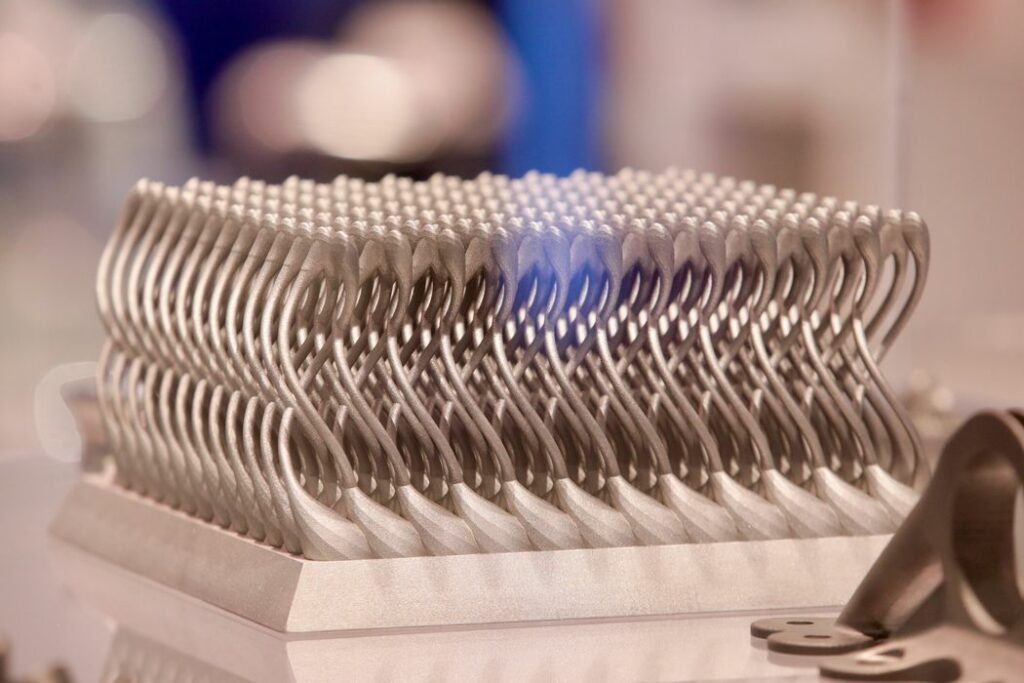

AM solutions shown will encompass equipment for both prototyping, the original use of the technology, as well as tooling and end-use parts, which are high growth applications for the technology. And, it is not just small parts that are gaining traction in AM. Large-volume print beds continue to expand and deliver precision and repeatability for different industry standards thanks to in-situ metrology and closed-loop controls.

Sample of AM Solutions in the AM Pavilion

One outstanding prototyping solution is Xact Metal’s XM200C metal 3D printer, to be exhibited at IMTS booth 433041. Although this device exhibiting a smaller build volume than most metal 3D printing systems, it carries an unheard of price tag: only US$65,000. It’s often used by educational institutions and as an in-house production system for tooling.

Another fascinating system is Hybrid Manufacturing Technologies’ AMBIT system, which is a swappable toolhead system allowing use of multiple additive, subtractive, and inspection processes on the same platform, with an ability to change heads in only seconds. AMBIT technology includes toolheads for a wide variety of making processes, including powder direct energy deposition, machining, pellet-fed polymer extrusion, non-contact inspection, laser scanning and much more. Hybrid Manufacturing Technologies will be present at IMTS booth 433137.

One metal additive system we’ve seen elsewhere is the SPEE3D system from Australia, to be presenting at IMTS booth 433027. This device uses a supersonic cold spray process to blast fine metal particles at a target. By moving the spray angle, the SPEE3D process can gradually build up solid metal objects in aluminum or copper.

Low volume production with additive processes is a hot topic these days, and several exhibitors will demonstrate systems that can automate the often manual processes associated with additive manufacturing. One to watch is 3D Systems’ Figure 4 system, which is a modular device that can not only 3D print solid objects in a variety of engineering resins, but also post process them automatically by moving print trays between stations on the Figure 4.

Those are but four of the scores of additive manufacturing solutions that will be on display in the AM Pavilion at IMTS 2022.

AM Solutions in the Metal Removal Pavilion

Visitors to IMTS 2022 will also find AM solutions embedded within metal cutting machines. Hybrid systems combine traditional subtractive processes with additional processes, including laser metal deposition additive manufacturing (AM) and friction stir welding (FSW).

Instead of using a stand-alone FSW system, which may have lower utilization rates, Mazak offers an alternative with its VTC-300c hybrid system, which offers everything users expect from a three-axis CNC, except that its powerful 40-taper spindle also accepts FSW tools. (IMTS booth 215218 and 338300) Instead of multiple workstations, some parts can be “done in one.” This removes the time and labor associated with moving parts between machining and welding stations. It also removes potential sources of error, such as losing zero due to refixturing.

“Adoption of hybrid systems will accelerate when large manufacturers design parts that require internal structures,” says Jim Kosmala, vice president of engineering and technology, Okuma (IMTS booth: 338500). “That will inevitably occur because mechanical engineers understand the strength, weight, and performance benefits of additive designs.”

Okuma’s MU-8000V LASER EX “super multitasking” CNC machine combines five-axis subtractive capabilities with laser metal deposition (LMD) technology for AM, hardening, and coating of workpiece blanks. By implementing LMD instead of laser metal fusion (LMF), this machine offers mid-process part inspection and material exchange, coolant use in work envelope, higher deposition rates, and three-dimensional fabricating. A 4kW Trumpf laser can supply power to up to four LASER EX machines. (Trumpf IMTS booths: 236217 and 433037.)

AM in the Quality Assurance Pavilion

Exhibitors in the Quality Assurance Pavilion at IMTS will showcase digital metrology solutions that enable users to optimize workflow, improve manufacturability, and increase quality.

Technologies making their pavilion debut include those for CT and CMM systems that can create a digital twin and output a file that drives 3D printers as well as traditional machine tools; automatic creation of measurement programs from 3D CAD models; self-learning (AI) CMM measurement programs that can be taught to ignore characteristics that do not impact quality; measurement of fragile parts, using non-contact optical techniques; and more options for non-destructive inspection; remote monitoring of machine status via a smart phone app. ZEISS Industrial Quality Solutions (IMTS booth 135502), Hexagon’s Manufacturing Intelligence division (IMTS booth 135202), Creaform (IMTS booth 135258), and more offer multiple digitally integrated metrology equipment.

AM in the Controls & CAD-CAM Pavilion

Advanced manufacturing has experienced a seismic shift in the democratization of digital manufacturing technologies designed for job shop use to increase CNC and 3D printer productivity. The first step to optimizing manufacturing and job shop efficiency starts with a visit to the Controls & CAD-CAM Pavilion, where exhibitors such as Autodesk, ESPRIT, Dassault Systemes, HEIDENHAIN, Mastercam, and more will showcase new digital twin and virtual solutions.

Other new product launches include machine and enterprise-wide monitoring software to identify bottlenecks and increase OEE, ERP systems that can reduce setup time and increase employee productivity, cybersecurity preparedness solutions, and advanced estimating and quoting software that enables job shops to respond to RFQs in hours, not days.

Beyond the Exhibits

New to the North American market and IMTS, the AM4U Area, presented by Formnext, will feature talks about adopting industrial AM into your production process., as well as entrepreneurship and business models. Highlights include:

- Discover 3D Printing seminars by Aachen Center for Additive Manufacturing (ACAM)

- Trends in Additive Manufacturing by AMT – The Association For Manufacturing Technology (AMT is the owner and operator of IMTS.)

- Cool Parts Show hosted by the editors of AM Magazine

- In addition. the AM 2022 Conference at IMTS, brought to you by Gardner Business Media, focuses on industrial applications for making functional components and end-use production parts. It will cover the processes, applications, and materials to give you practical knowledge on how to implement AM in your facility.

The Future, Now!

IMTS 2022 will again host AMT’s Emerging Technology Center presenting the absolute latest advancements just on the horizon. You’ll see the AM equipment, processes, and materials manufacturers are presently using to drive outer space missions for long-term presence on the moon and deep space exploration.

See it all at IMTS 2022, September 12-17, 2022, McCormick Place, Chicago, Illinois. Get a head start, discover more at IMTS.com and register at IMTS.com/Register.