AM Ventures announced an investment in startup Scrona AG. But what’s so important about this company?

They don’t make 3D printers or materials, but instead have been developing a rather unique printhead that could revolutionize future 3D printers.

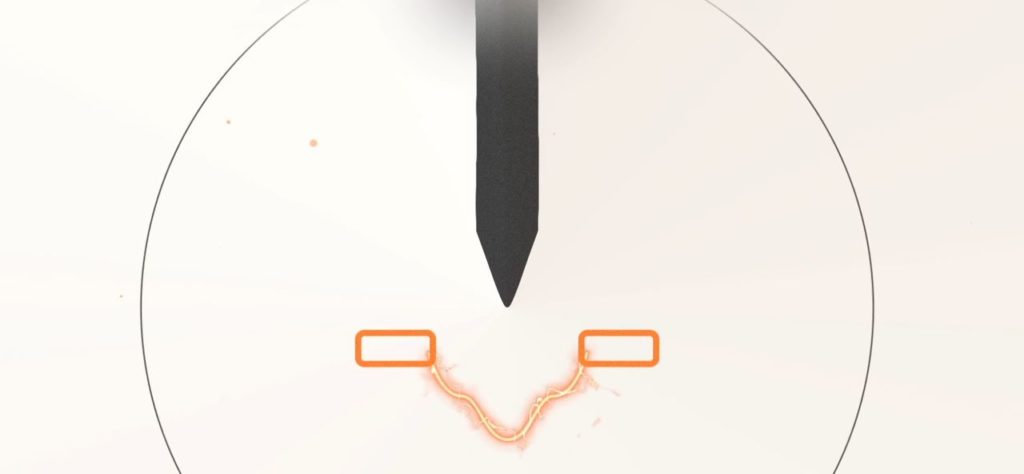

The Scrona printhead uses what they call “EHD Technology”, which is short for “ElectroHydroDynamic”. In a gross oversimplification, the printhead simply drops a uniform droplet of liquid material onto a surface below. But it’s how EHD does this that is interesting.

Conventional liquid printheads use a pressure-style approach to push a liquid through a tiny nozzle to form the droplets. By placing many of these nozzles in parallel it is possible to create a printer. Imagine an arm fitted with these nozzles, and have it sweep across a surface with droplets falling in such a way to completely cover the print surface.

That’s how high speed 2D printing takes place today, and in fact the same principle is also used for some 3D printing processes. A binder jet system, for example, might sweep across a flat bed of polymer powder, selectively depositing binder where the object is to be solid. These systems can be quite fast as the sweeping motion is similar to that of high speed 2D printing. However, many layers must be done in order to complete a print.

This droplet approach to 3D printing is limited in a couple of ways. First, the ability of the printhead to emit more droplets has a short delay. This ultimately moderates the maximum speed an arm can move during a print operation.

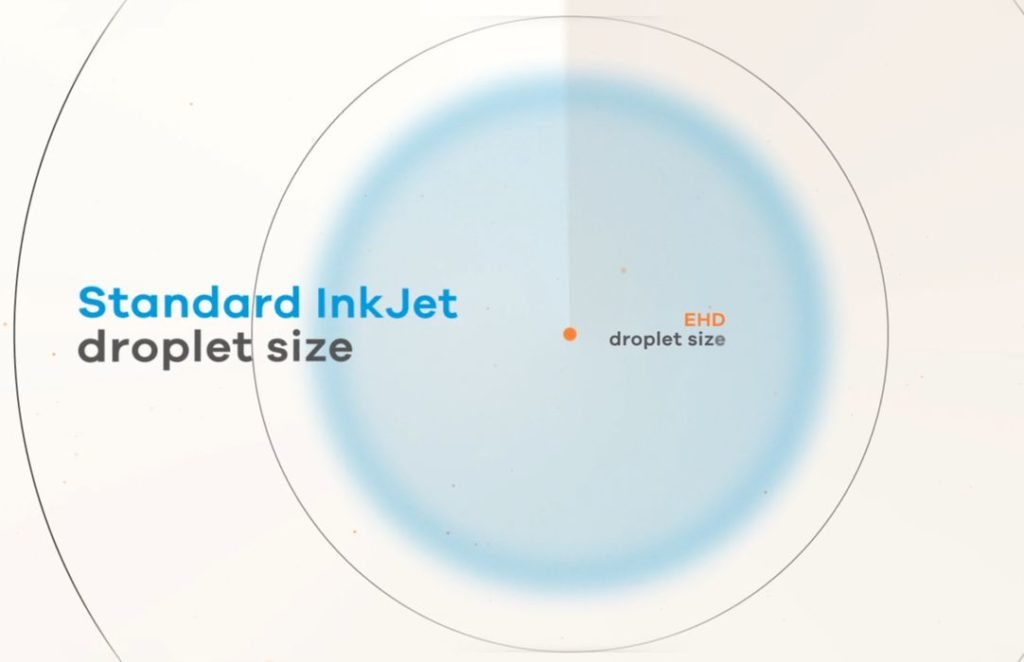

Secondly, the maximum resolution obtainable in such a system depends on the size of the droplets. You can’t make features smaller than the droplet.

Regardless of these limitations, this type of 3D printing has been quite successful. However, with Scrona’s new EHD technology things could change.

EHD technology involves using an electrostatic method to create droplets. Instead of back pressure pushing out a droplet through a nozzle, an electrical field pulls a tiny drop from the tip of the nozzle. These droplets can be 100X smaller than conventional droplets, with the implied affect on print resolution. The small size of the droplets also speeds drying, if that is what is to happen with the liquid material.

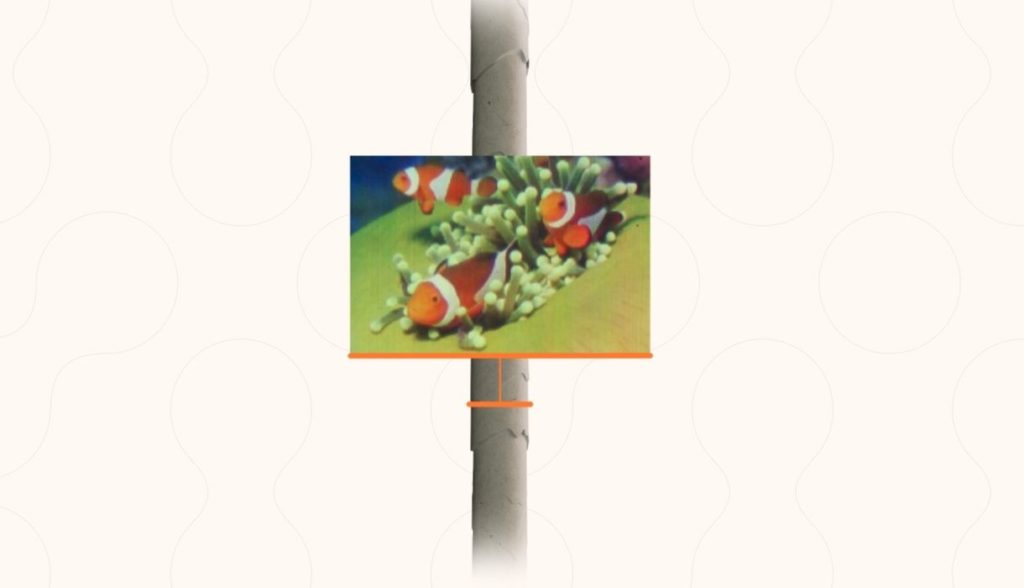

In fact, Scrona posted an image of a 2D full color print, as seen here:

What’s that pole behind the picture?

It’s a human hair. Now that’s high resolution, wouldn’t you agree?

If that wasn’t enough, the EHD printhead can also handle materials far more viscous than can be used on conventional printheads, apparently 100X more viscous. They say it can process materials including: molecules & salt solutions, microparticles, proteins, melts, waxes, epoxies, and much more.

This has another implication. Conventional droplets tend to be less viscous and thus they will spread out wide when impacting the surface. This means you end up with a thin deposition. In contrast, the EHD droplets are more viscous and end up having much more “Z” than liquid droplets. This means a 3D printer using this printhead could build thicker layers and whole objects faster.

EHD has yet another advantage: speed. They say the droplet frequency is 10X that of conventional print heads. This means that the sweeping arm could potentially move at 10X the speed and still get 100% coverage of the print surface.

Finally, Scrona has been able to create chips containing 1000 of these printheads all in parallel. This means that a potential 3D printer could equip a long sweeping arm with several chips to gain a wide print volume. It would also be possible to have multiple chips/arms loaded with different kinds of materials for multimaterial prints.

What we have here is a “super printhead” capable of both high speed and high resolution. It will almost certainly be used in future 3D printers, and I have little doubt someone is already working with Scrona on that at this moment.

We could see EHD technology supercharge existing 3D printers using this type of liquid printhead, or we could see new entrants suddenly appear with ultra-fast 3D printers. Or both. Note that TRUMPF is one of the new investors.

There’s one more point to make here. While these printheads do offer ultra-high resolution, it’s unlikely that will be used for larger objects. Typically larger items don’t require particularly good resolution, and one might wonder where EHD would fit in the 3D printer spectrum.

My thought is that we would see a large format 3D printer using EHD technology, but that it would be used to print smaller, high resolution objects en masse. Instead of printing a big object in the build volume, print 1000 smaller high resolution items. In other words, I see EHD as a means to achieve very high production throughput for an additive manufacturing organization.

What are your thoughts on this technology?

Via Scrona and AM Ventures