Researchers have developed “iCLIP”, a new 3D print process that is 5-10X faster than current resin 3D printing processes.

You might recall “CLIP”, the advanced 3D printing process used by Carbon. CLIP enables substantially faster 3D printing than typical resin approaches because it eliminates a tedious portion of the build sequence.

In SLA, MSLA and DLP processes, each layer is built on the bottom of a resin tank. The laser (or light engine) solidifies a layer of resin, but also tends to bond the new layer to the resin tank. This necessitates a slow “peel” sequence where the new layer is slowly pulled off the tank surface. This is done on each and every layer, and significantly delays printing.

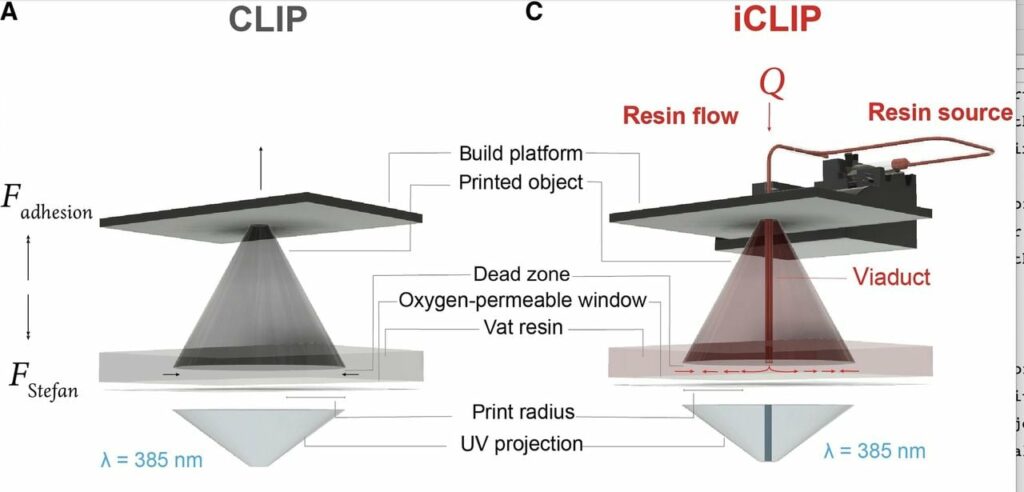

CLIP is a bit different in that it has a special tank bottom that permits oxygen molecules to penetrate. This creates a thin layer of oxygen mixed with the resin at the bottom of the tank. This is important because the oxygen inhibits the resin from polymerizing, meaning there is NO adhesion to the tank. The printing can proceed without delay, hence the greater print speed.

So can you really 3D print faster. The answer is yes and no. For typical resins this is indeed the case, but for more viscous resins it is not.

While CLIP prevents tank adhesion, the process still requires fresh resin to flow into the space as the build plate lifts on each layer. If the resin is thick, then that flow can be quite slow and we’re back to slow prints again. This is especially true for “solid” prints (think of a “brick”) but less so for spindly prints (think of the Eiffel Tower).

It now appears that researchers at Stanford have figured out a way to make this go much faster.

Based on CLIP, using an oxygen-permeable tank window, their new iCLIP process is brilliant: instead of waiting for fresh resin to flow in from the sides after a layer completes, they inject resin into the gap.

The resin is injected from the build plate itself, using a large number of micro fluidic channels. Basically the build plate “bleeds” resin after each layer, eliminating the flow delays.

The implication here is that iCLIP could use far more viscous resins, and that’s a good thing.

3D printer resins are essentially composite materials that include the base photoinitiators and other ingredients that determine the material’s properties. If you are limited to less viscous resins, there are fewer ingredients you can add to the mix.

The possibility of more viscous resins means there will be far more advanced and interesting resin materials that can be 3D printed.

There’s more.

The elimination of “suction forces” during these movements means it will be possible to 3D print more delicate objects and also better retain object dimensionality and reduce delaminiaton. They explain:

“As a result, resins with highly attractive material properties that are too viscous for CLIP are thus accessible to iCLIP, at high volumetric throughputs. Multiwalled carbon nanotubes (MWCNTs), for instance, are extremely attractive additives for their electrical, thermal, and mechanical properties, with applications in, e.g., strain sensors, wearable electronics, and structural health monitoring. iCLIP can readily process such a filled resin, forming a body-centered cubic lattice with MWCNT-filled resin flowed through lattice struts at percolation threshold–exceeding concentrations (23) without cavitation.”

Hold on, there’s even more here.

Because the injection process can be controlled, it’s possible for iCLIP to inject DIFFERENT resins into the build space during a print job!

”iCLIP, by mechanically injecting different resins through viaduct(s), can create multimaterial composite architectures in all three Cartesian dimensions. Because no commercially available multimaterial AM design software is available, we implemented a custom CFD simulation–guided and microfluidics-enabled multimaterial control methodology. In a multimaterial iCLIP–printed part, resin may either be supplied by the vat or through injection.”

This, I believe, could be the first time anyone has figured out how to 3D print multiple resins in a single print job using vat technology. I have many questions about this, however, such as what kind of a Frankenstein resin remains in the build tank afterwards, and can it be reused? They do address this question:

“Resin contamination during multimaterial iCLIP printing, and thus the potential for added waste, also presents a concern; however, if all injected resin is consumed by part production, as demonstrated by calibration experiments in Fig. 4, then the remaining resin in the vat can be recycled.”

This is fascinating stuff and will absolutely be commercialized if it isn’t already underway somewhere. It may even be that Carbon is involved, as one of the paper’s authors is none other than Joseph DeSimone, founder of Carbon.

Via Science Advances