The UK’s high-speed rail project, HS2, will use advanced construction 3D printing.

Rail in the UK is an essential element of everyday life; almost everyone takes a train of one kind or another, daily or weekly. The country was the birthplace of rail travel in 1804, and today that small step has covered not only the UK, but the rest of the world.

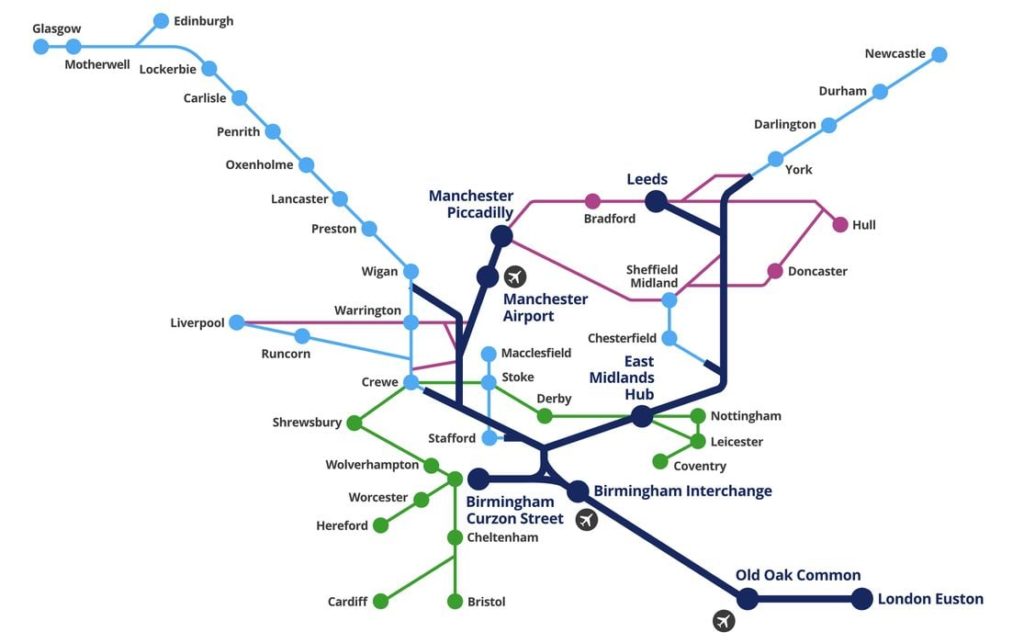

The UK continues to improve its rail network, and one of the biggest projects is “HS2”. It’s an initiative that is to dramatically improve service between London and seven of the country’s ten largest cities in the Midlands, the North and Scotland.

The project focuses on high-speed rail to solve a current issue: today’s high-speed trains use existing railways, causing conflicts with slower-moving local trains. The HS2 concept involves building a second, dedicated rail specifically for high-speed train use. HS2 explains the benefits:

“By building a new railway line, HS2 takes fast trains off the existing railway and places them on to their own dedicated tracks, better connecting our major towns and cities. This then allows slower, local trains to bunch up on the existing lines, freeing up space across the country for many more commuter services and freight trains.”

That makes sense, but building a second railway line is a big deal. This map shows the amount of track to be laid after all three phases are completed:

The sheer amount of railway line to be built here means that any seemingly small improvement to the efficiency could result in massive savings. To that end, HS2 has been exploring different approaches to all aspects of the project, and one of them involves 3D printing.

The plan to be executed by HS2’s contractor, SCS JV, is to 3D print rail sections in place rather than traditional methods. In past projects concrete slabs would be cast at a factory, loaded on trucks and shipped to the build site for assembly with cranes.

That process will now be quite different. Robotic 3D printers will extrude the concrete structures in place. The only thing to be moved will be the robots themselves as they proceed along the railway line.

This approach dramatically changes several aspects for the project. Far less shipping will occur, as will the need for assembly, cranes and their operators. Not only will money be saved, but also CO2 emissions due to the lowered amount of transport.

You might be wondering how this could work without the use of steel reinforcing material, which is typically used in structural projects. Here HS2 will use a unique solution that I suspect will be used in other projects in the future.

SCS JV has partnered with materials specialist Versarien and ChangeMaker 3D to develop a composite extrudable concrete mix that includes graphene.

Graphene is a 2D material made from a hexagonal lattice of carbon atoms. It’s one of the strongest possible materials, and its inclusion in the mix will make the concrete one of the strongest ever produced.

The strength of the material will allow the project to 3D print railway structures using a lattice approach that will significantly reduce the amount of concrete used. Again there are savings due to this, but importantly the lowered amount of concrete will very significantly reduce the amount of CO2 generated. Cement production requires very high heat for long periods, so it’s important to minimize the concrete used.

The HS2 project is very likely the largest 3D printing project of any kind to be undertaken. However, if it is successful it is likely similar approaches would be used in other regions, and not just on rail projects.

The demand for construction 3D printing continues to rise.

Via HS2