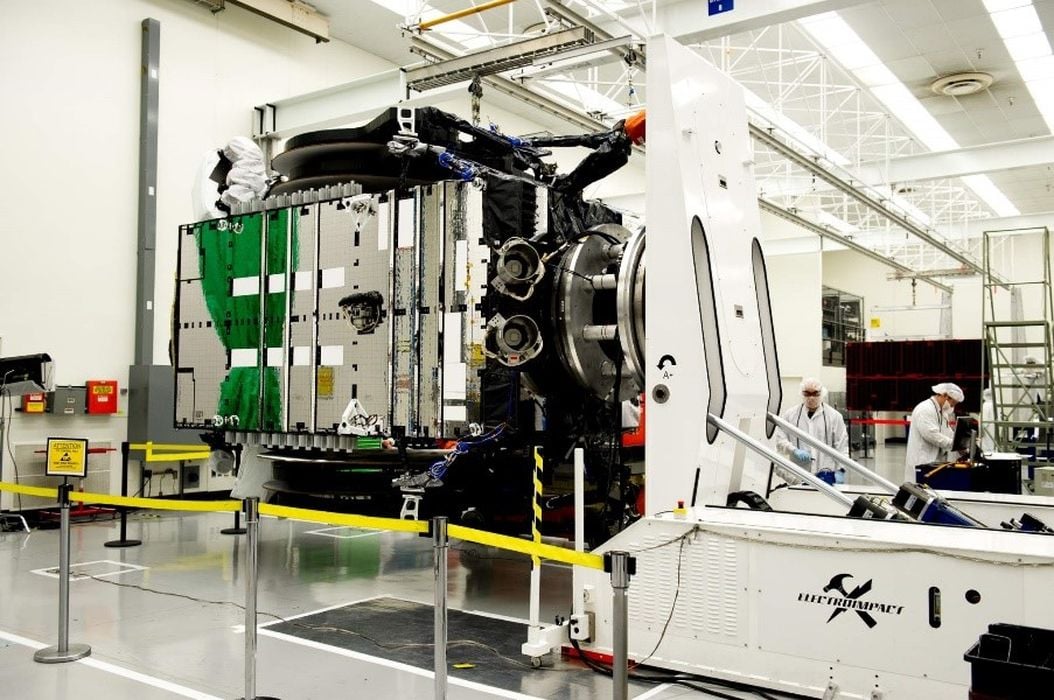

SES-15 satellite by Boeing involved 3D printing to make [Source: 3DEO]

Preeti Sulibhavi and Charles Goulding look at the 3D print possibilities that may open up should United Launch Alliance (ULA) be sold.

ULA is the rocket launch business jointly owned by Boeing and Lockheed Martin. With 155 successful missions spanning nearly 15 years, ULA has established itself as the most reliable launch provider in the industry. The company’s largest customers are NASA and the Department of Defense (DoD), who rely on ULA to deliver critical national security and scientific payloads into space.

However, change may be on the horizon for this staple of the aerospace sector. Since early 2023, rumors have swirled regarding the potential sale of ULA. Among the rumored bidders are Jeff Bezos’ Blue Origin commercial space firm, private equity giant Cerberus Capital Management, and an unnamed major aerospace company. As an established player in the launch services marketplace, Blue Origin potentially stands to gain the most from an ULA acquisition. Absorbing ULA’s contracts, expertise, and launch vehicles would bolster Blue Origin’s position in the sector.

Of course, with any joint venture, there is always the possibility that one of the parent companies could emerge as the buyer. As 50% stakeholders in ULA, either Boeing or Lockheed Martin could look to take full ownership. Regardless, any sale would need to pass regulatory scrutiny from the FTC and Department of Justice based on competitive and national security concerns.

Integral to ULA and the future of the space industry is the advancement of 3D printing technology. All ULA’s major stakeholders have made substantial investments in 3D Printing over the past several years across rocket production, satellites, and space exploration.

Boeing has utilized 3D Printing to construct intricate rocket engine parts and satellite components that are lighter and more resilient than conventional manufactured parts.

3D printing at Boeing has now become “part of our standard design processes.” The company isn’t alone either as 3D printing is becoming increasingly pivotal to accelerate satellite production and reduce lead times, as well as provide complex design options.

Boeing launched the SES-15 satellite, which included over 50 metal 3D printed components and represents Boeing’s new approach to innovation.

Many satellite manufacturing companies have begun complimenting their production processes with 3D printing and British company Surrey Satellite Technology is quoted as saying that 3D printing is “changing the economics of space.”

3D printing is also used for the creation of smaller satellites referred to as “cubesats.”

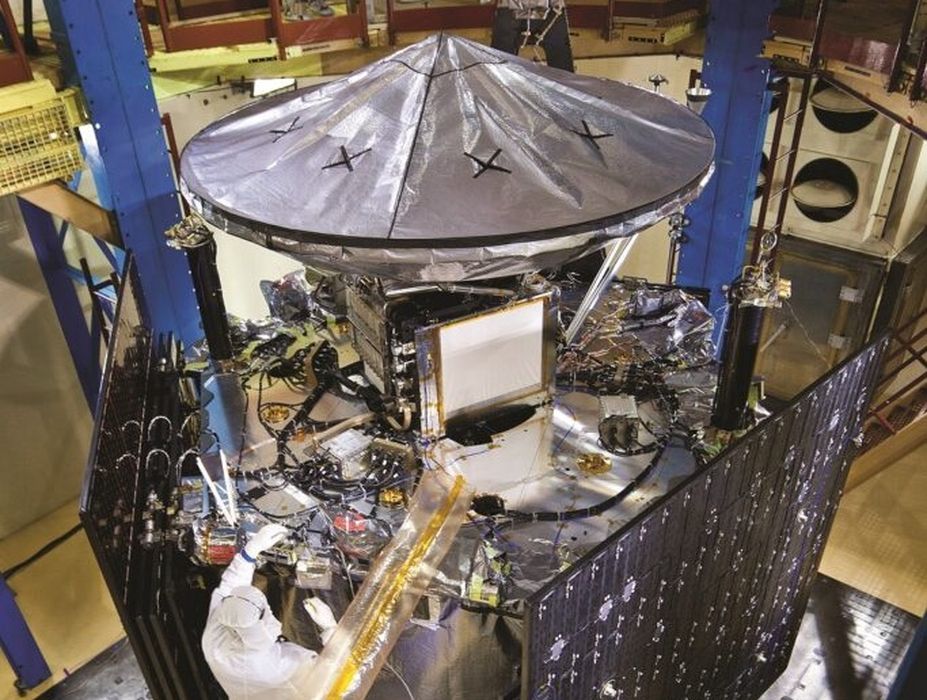

Lockheed Martin has printed various spacecraft parts needed for NASA’s Orion exploration program. The printed Orion parts include environmental seals, cable trays, and even a 3D printed shelter used by astronauts.

NASA relies on 3D printing for an array of space applications, like fabricating rocket test components and extraterrestrial habitats. The space agency has also installed 3D printers aboard the International Space Station (ISS) to provide crews with on-demand tool production.

The Air Force has worked extensively with 3D Printing technology to sustain aircraft and manufacture rocket parts that are no longer in production. The Air Force, in collaboration with Essentium, worked to develop and deploy 3D printing applications in tooling, ground support, maintenance, repair and overhaul (MRO), and flight-certified parts for military aircraft and ground vehicles. These components will be delivered to the US Air Force and the National Guard Bureau (NGB) in a bid to save both services millions of dollars.

The US Air Force tested and prototyped new materials and processes using the Essentium High Speed Extrusion (HSE) technology. The US Air Force tapped into Essentium’s materials expertise to enable drop-in replacements for Military Specified materials, such as phenolics, and is targeting the certification of four times the quantity of materials at reduced cost and time than is currently possible with the technology solutions used by the Air Force.

As the launch industry continues evolving, the expertise and resources required to leverage 3D printing will only become more vital. Any prospective ULA buyer would be wise to understand the incumbent aerospace companies’ substantial existing investments in 3D printing. Doing so would allow them to fully capitalize on synergies across this innovative set of technologies and processes.

We have previously covered the relevance of 3D Printing with rockets in multiple Fabbaloo articles including our review of the Ashlee Vance’s book “When the Heavens Went on Sale: The Rocket Pioneers Revolutionizing Space” and “3D Printing Implications of the L3Harris Technologies Acquisition of Aerojet Rocketdyne.”

The Research & Development Tax Credit

The now permanent Research & Development Tax Credit (R&D) Tax Credit is available for companies developing new or improved products, processes and/ or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits

Conclusion

The potential sale of rocket pioneer United Launch Alliance will be an intriguing storyline to follow across the aerospace sector. Considering ULA’s prestige and deep-space customer relationships, the bidding process is likely to draw immense interest. Ultimately, the winner will obtain not only well-established rockets but also an opportunity to deploy additive manufacturing techniques that can transform space systems production.