I’ve been using Simple Green as a resin 3D print solvent, and it works quite well — if you know what to do.

Most people use isopropyl alcohol (IPA) to clean 3D prints, and it works extremely well. The most effective IPA is 91% pure, which apparently works a bit better than 100% IPA. However, there are a number of issues with IPA:

- It can be expensive, particularly at points during the pandemic

- It is highly flammable

- It is toxic

- It can open the pores of your skin, which permits easier absorption of both IPA and the toxic resin dissolved in the IPA

As a result, many resin 3D printer operators are a bit wary of using IPA, including myself.

Are there alternatives? There are indeed.

One approach is to use water-washable 3D printer resins. To clean them you can literally substitute fresh water for IPA and use the same process. Just make sure you don’t put the dirty water down the drain, because it contains, you guessed it, toxic resin. You’ll have to sit the dirty water in the sun to allow its UV rays to solidify the resin, which show up as loose bits at the bottom. Sift them out and toss them, and you can even reuse the water for additional cleaning.

However, the choice of water washable resins is far less broad than traditional “IPA” resins, so many people continue to avoid water washable options.

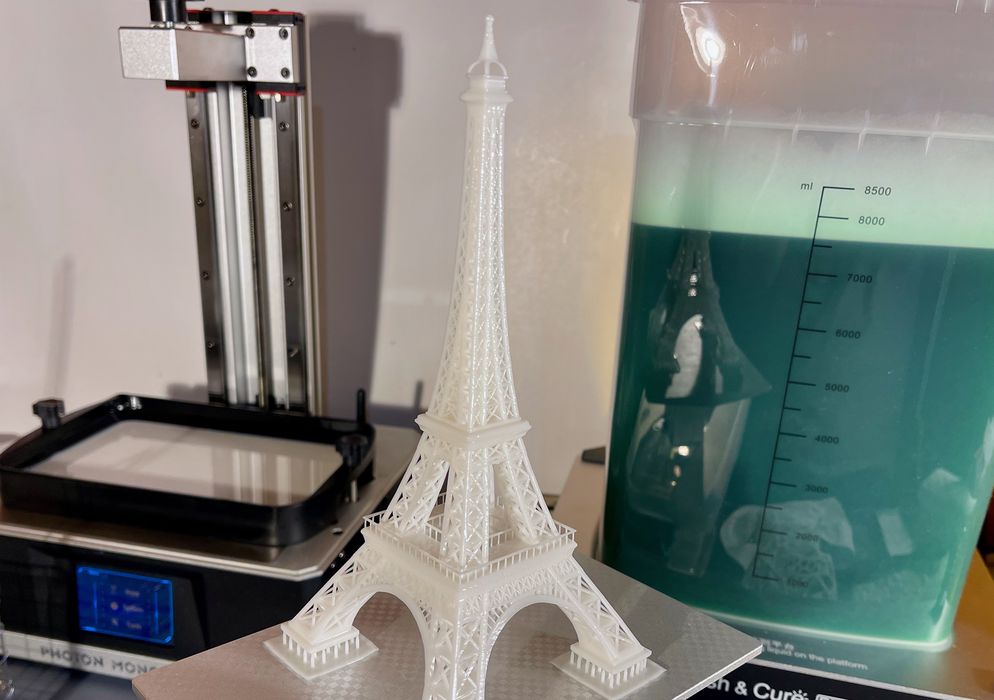

In my case, I happened to be testing the new Anycubic Photon Mono X 6K, which is used with the accompanying Wash and Cure Plus Machine. This highly capable washer is able to handle the large print jobs that come off the 6K, and so it has a massive wash tank volume of 7L.

Given the issues with IPA listed above, and in particular the flammability, I wasn’t keen on having 7L of IPA lying around waiting for trouble.

I looked into alternative resin solvents, and several have been described elsewhere. One that caught my eye was something called “Simple Green” by Sunshine Makers, Inc., which is commonly available and is quite inexpensive. This solvent comes in two formulations, regular and a “Pro” version for heavy-duty cleaning. I used the regular formulation, because it was cheap and turned out to work well enough. Also, it apparently comes in different scents, including lemon and lavender, if you’re picky on smells. My choice was the default “green” version, which comes with a strong detergent smell.

To use Simple Green, simply use it instead of IPA. I filled my massive wash tank with two jugs of regular “green” Simple Green solvent, and was ready to proceed.

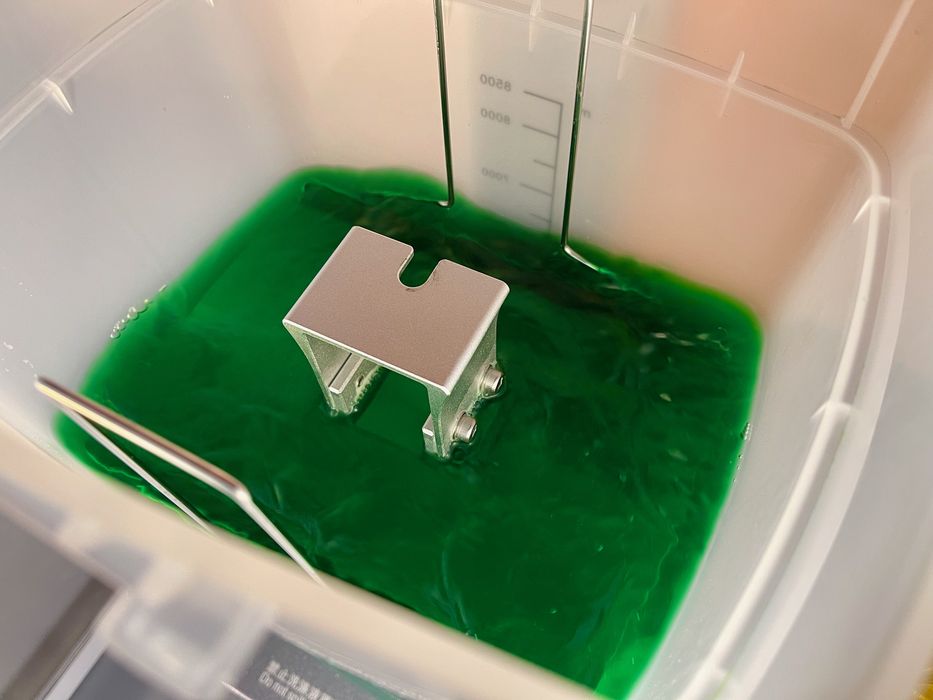

The first thing I noticed was that Simple Green seems to work differently than IPA. IPA dissolves resin, and after a few cleanings IPA tanks typically become cloudy, being polluted with toxic resin. However, resin in Simple Green seems to act differently. Instead of dissolving, it clots up and sinks to the bottom.

When I turn on the circulation of the washer, I always see some globs of previously cleaned resin float up from the bottom.

Does Simple Green clean off wet resin? Yes, indeed it does. I found that resin comes off within a few minutes. Typically I’ve been running the washer for only ten minutes on every 3D print, and perhaps it might even be possible to run it for shorter durations. But ten minutes is pretty quick.

One issue I found that occasionally occurs when using Simple Green is foam. Here we can see my Eiffel Tower print covered in green foam. While it looks bad, it really isn’t: just scrape some off and wash with water.

I initially thought I had completed the wash process, but that was completely wrong, and this is where the special steps came in.

3D prints cleaned with Simple Green are indeed free of resin, but they don’t appear to be so. They have a slimy feel on the surface.

I initially thought this slime was uncleaned resin, and that the Simple Green hadn’t actually cleaned it off completely. To fix it, I placed the print in the curing station to solidify this remaining resin.

However, I was wrong: after pulling the print out of the curing station, it was still slimy. Even leaving the slimy print in the sun for a half day didn’t remove this apparent resin.

That’s because it wasn’t resin — it was actually Simple Green residue.

The question then was, how does one remove the Simple Green slime? The answer turns out to be IPA.

The use of IPA somewhat contradicts the original intention of avoiding IPA and using only Simple Green, but I don’t see a way around it. Here’s what I did.

I organized a far smaller, 1L plastic tub to contain the 91% IPA. This was just large enough to hold the prints after removal from the print plate, and safer than having a massive 7L of IPA on the work table.

I found that a moment’s swish in the IPA completely removed the Simple Green slime.

Mission accomplished — but actually not.

While I found the IPA-swished parts to be entirely dry and slime-free, they still had a very strong odor. That odor, as you might have guessed, was that of Simple Green.

At first I tried to ignore this pungent aroma, but after a while it began to bother me due to its strength. I could not sit beside one of these prints because the smell continues to leak out, and eventually I sought a method to remove the offensive “Green” odor.

That method turned out to be a soak in the IPA. I found that if I placed the completed prints in the small, static IPA bath to soak for a few hours, even with no circulation, they would emerge with absolutely no odor whatsoever.

My new resin post processing steps now became:

- Finish the print job

- Scrape off stray resin back into the 3D printer’s resin tank

- Place the entire print plate, with attached prints, into the wash tank filled with Simple Green

- Circulate the Simple Green for ten minutes

- Remove the washed print plate and let drip back into the wash tank, turning occasionally to ensure pockets of Simple Green decant

- Wash the Simple Green off the print plate and prints with plain water

- Remove the 3D prints from the plate with a chisel

- Place the 3D prints in the IPA bath and let soak for a couple of hours to remove slime and odor

- Remove prints from the IPA and let air dry

- Remove support structures from the prints

- Trim or file off support stubs from prints

- Cure finalized prints for a few minutes

I’ve found this process to be entirely reliable and relatively safe. Prints produced are near-perfect, odorless and strong. The IPA also doesn’t have toxic resin dissolved within it, and remains clear. Although there is IPA involved, it’s far less than the massive 7L that would otherwise be required, and I feel much better about it.

While my process uses Simple Green, it’s likely a similar process might be required when using alternative, but similar detergent-style solvents.

Hopefully this may help you with your resin cleaning process, and possibly increase safety and ensure your resin 3D prints are the best quality possible.

Hi Kerry!

I too love the safety aspects of cleaning prints with Simple Green – also how long it lasts before needing to replace! Do you use full concentrate or dilute to say 50/50 with water?